| Informational Websites | ChronoMaddox -- the legacy of Chuck Maddox | OnTheDash -- vintage Heuer website | Zowie -- Omega information |

| Discussion Forums | ChronoMaddox Forum | Heuer Forum | Omega Forum |

| Counterfeit Watchers | ChronoTools Forum | ChronoTrader Forum |

|

|

The largest independent, non-commercial, consumer-oriented resource on the Internet for owners, collectors and enthusiasts of fine wristwatches. Online since 1998. | |||||||

|

||||||||

|

||||||||

|

Vintage Heuer Discussion Forum

The place for discussing 1930-1985 Heuer wristwatches, chronographs and dash-mounted timepieces. Online since May 2003. | ||||||

| |||||||

| |||||||

Fantastic posting . . . let's save as a blog posting, for the whole world to see!! [As a blog posting, it will be easier to update / revise, should you want to do so.]

Jeff

++++++++++++++++++++++++++++

: Hi all,

: some time ago I started to service some of my watches (the cheapest

: one like this Monza, surely not the Monacos ;-) ) and I

: documented, for myself, all the dismounting procedure...until

: now I don't think a similar post has ever been posted so I hope

: to please you all showing how an Heuer Cal15 (but is the same

: for a Cal11 or Cal12, chrono module apart) is made, part after

: part...

: I only recommend, if you want to service one, to do it at your own

: risk, is easier to damage it rather than make a good job if you

: don't have a bit of experience and don't know some tricks (I

: started with a movement bought on Ebay and had the help of an

: exceptional person..thanks again mate).. but is neither so

: impossible...

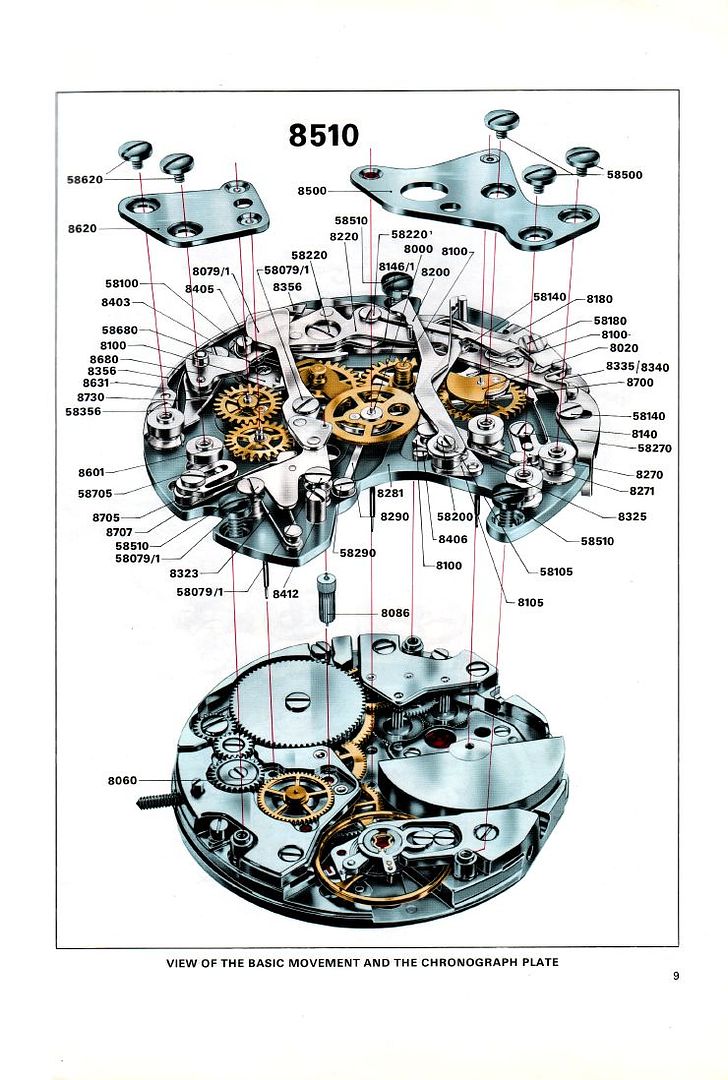

: This images are taken from the service manual and contain an

: exploded of the main parts (the chrono module and the basic

: movement):

:

:

:

:

:

:

: First of all you have to uncase the movement from the case,

: assuming you have already opened the caseback start unscrewing

: the 5443 (sorry the image is wrong, is not 5446) setting lever

: screw (1.5 turns, not more !!) and pull outward the stem 401

: with the crown, then unscrew the two 5166 casing clamp screws

: and remove (or simply push inward) the two 166 casing clamps:

:

:

: Then take the watchmaker's cushion and put it upside-down on the

: movement, turn the watch together with the cushion and the

: movement should remain on the cushion while you lift the case.

: Next step is removing the hands (you need specific tools to do it

: and can risk to bent or damage them, I always have a bit of fear

: every time I have to do it, anyway is a mandatory step and not

: the argument of this post) and the dial: to do this unscrew the

: two 5750 dial screws (are located on the movement's sides at

: 1.30 and 8.30):

:

:

: Then take apart the 498 washer (very thin, take care) and the 145

: dial rest:

:

:

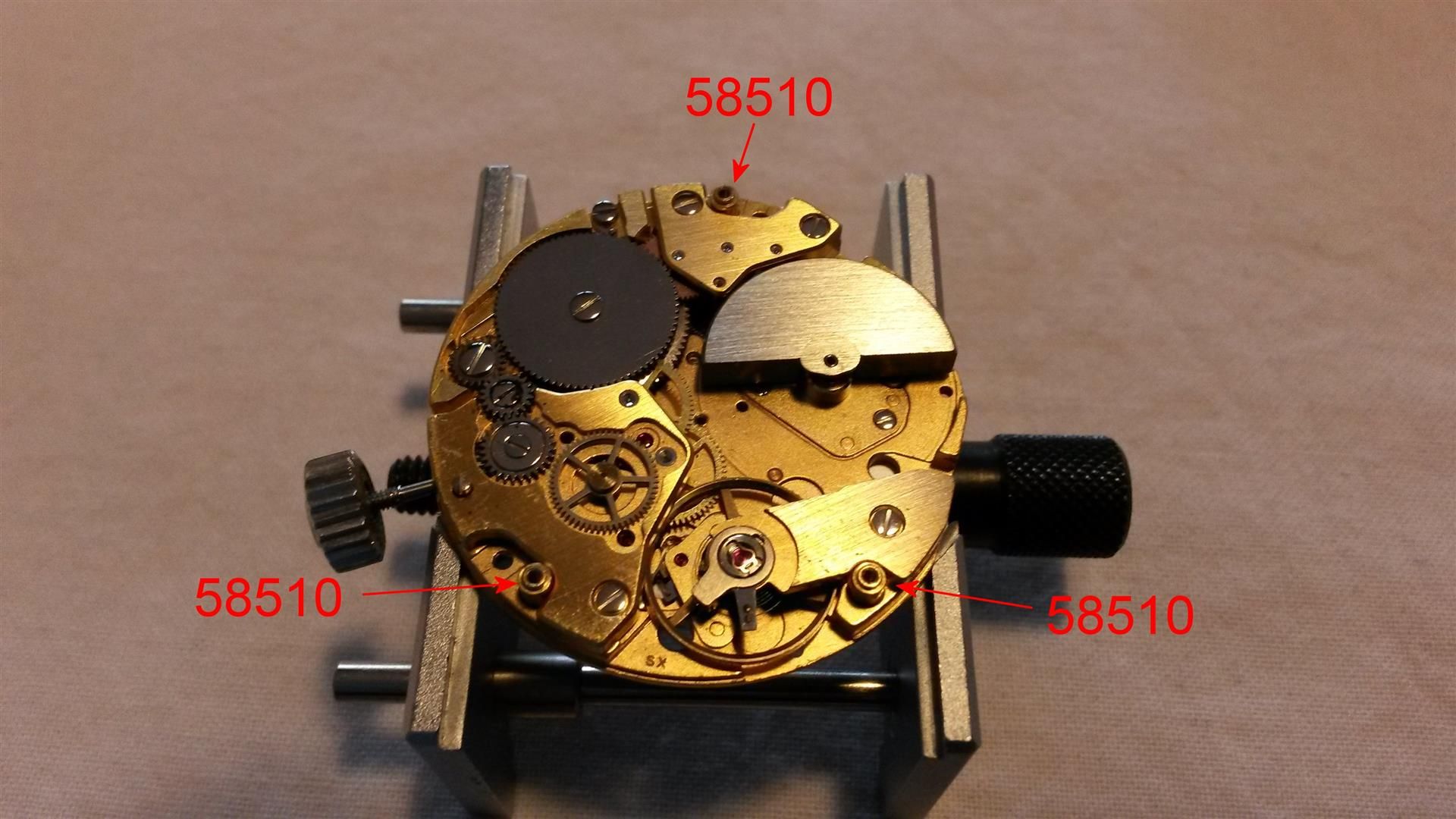

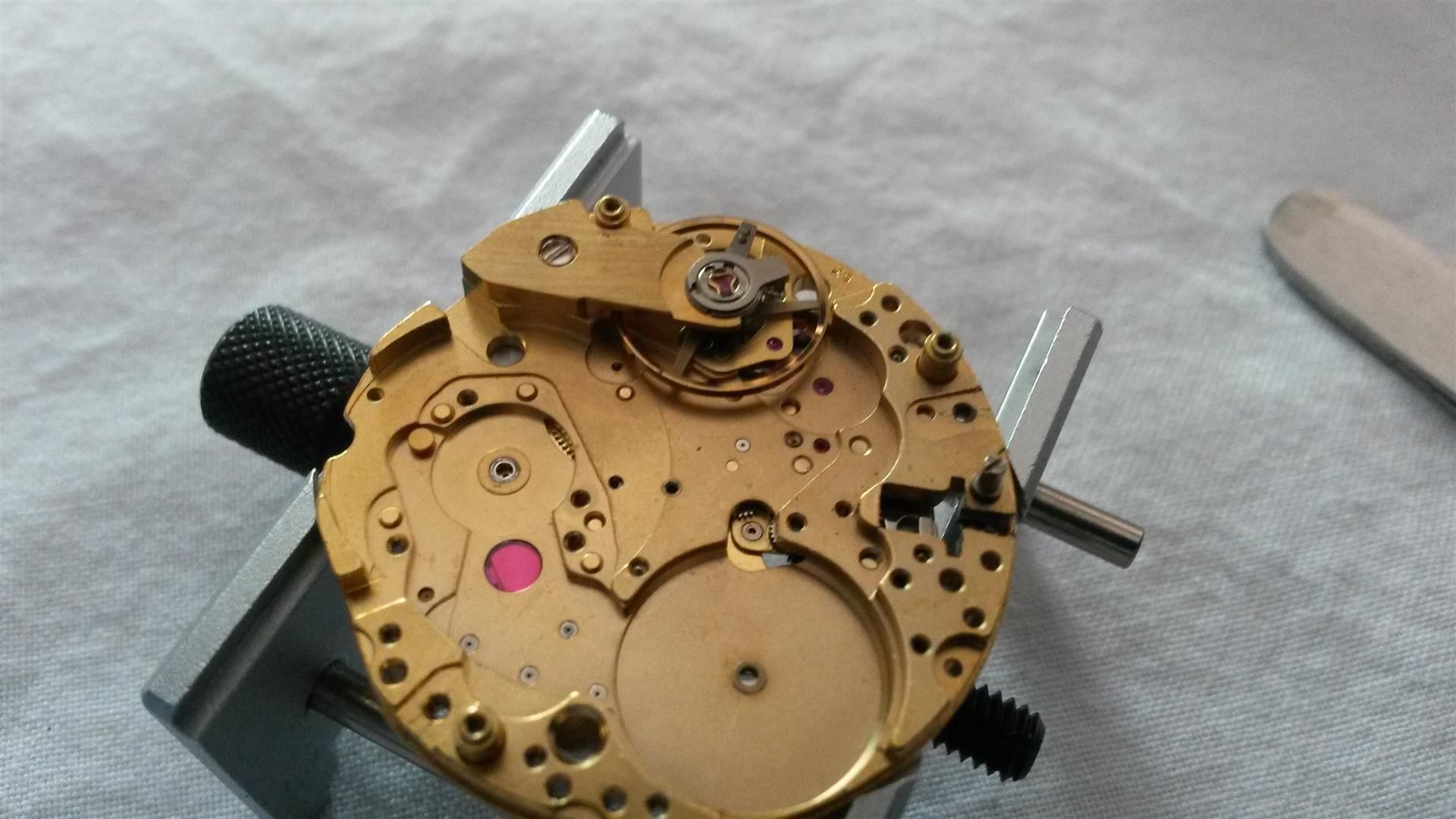

: Now put the movement on the clamp and remove the chrono module

: unscrewing the three blue 58510 screws (the following image is

: of a Cal12 movement, not 15, but screws are located in same

: place):

:

:

:

:

: Take care because probably the 8086 oscillating pinion will remain

: attached to the chrono module, so remove it gently (avoid

: damaging with the plier its small teeth):

:

:

: Take apart and store the chrono module as isn't necessary to

: dismount it, simply wash it with the ultrasonic bath, just some

: parts like the chrono bridges will be removed after washing for

: oiling some parts.

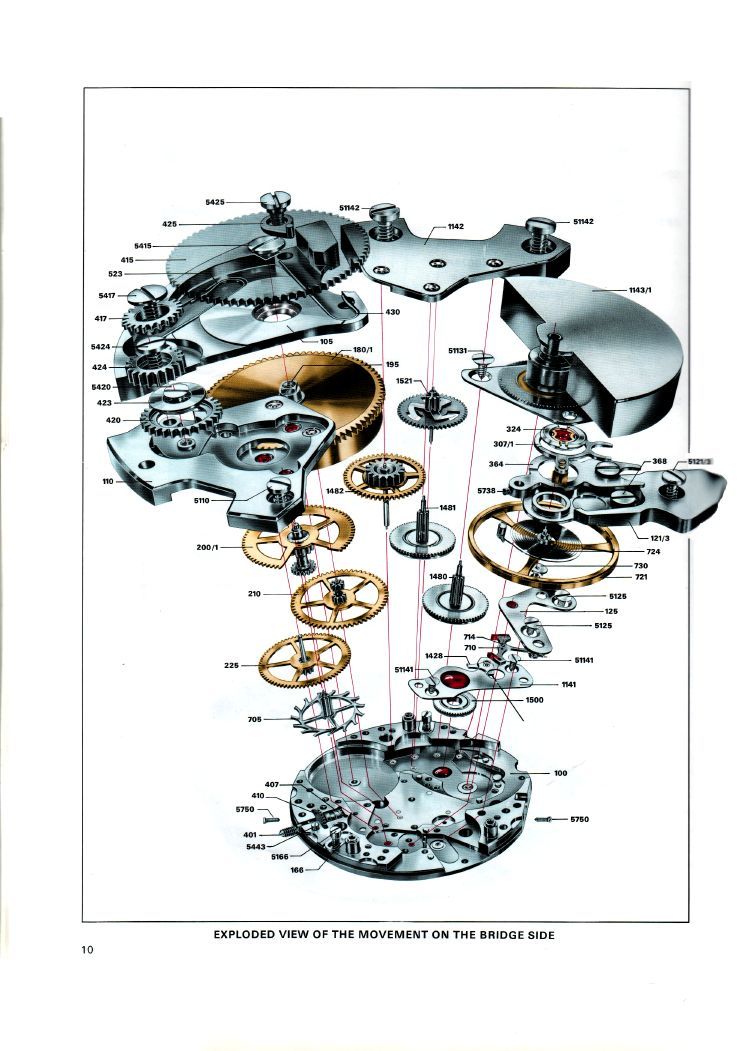

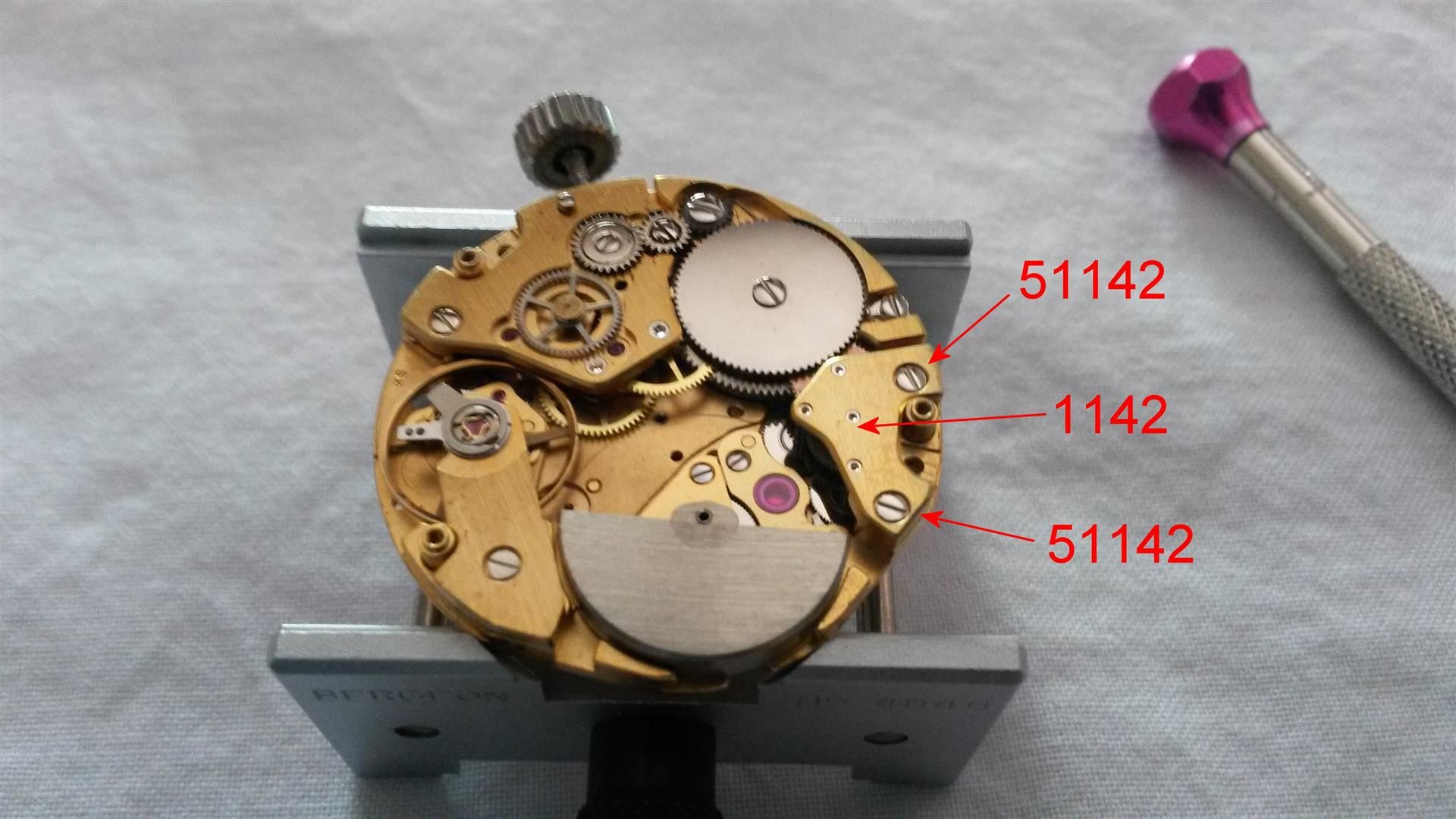

: Now let's start to dismount the main module: remove the 1142 upper

: bridge for automatic device unscrewing the 51142 screws:

:

:

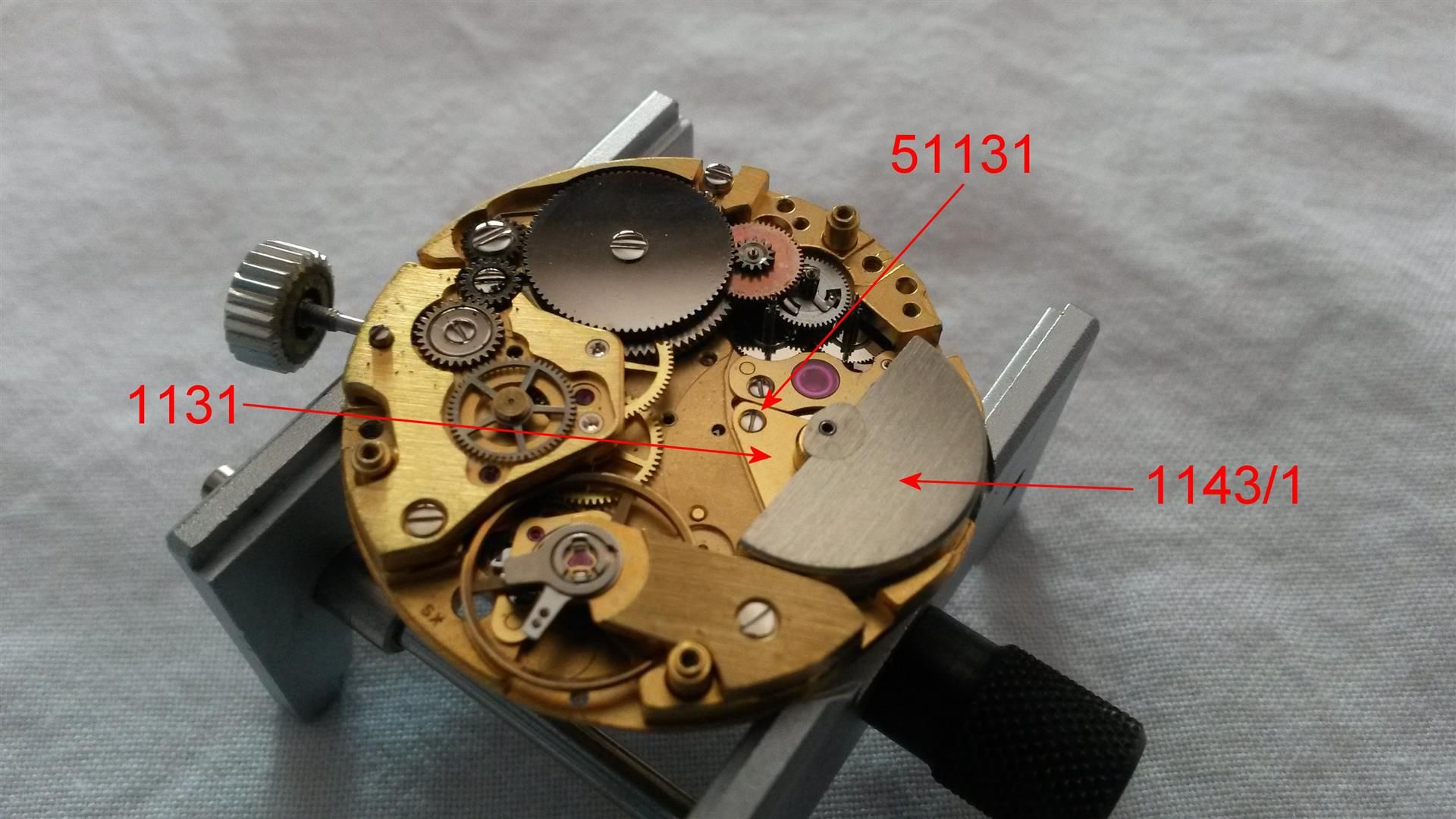

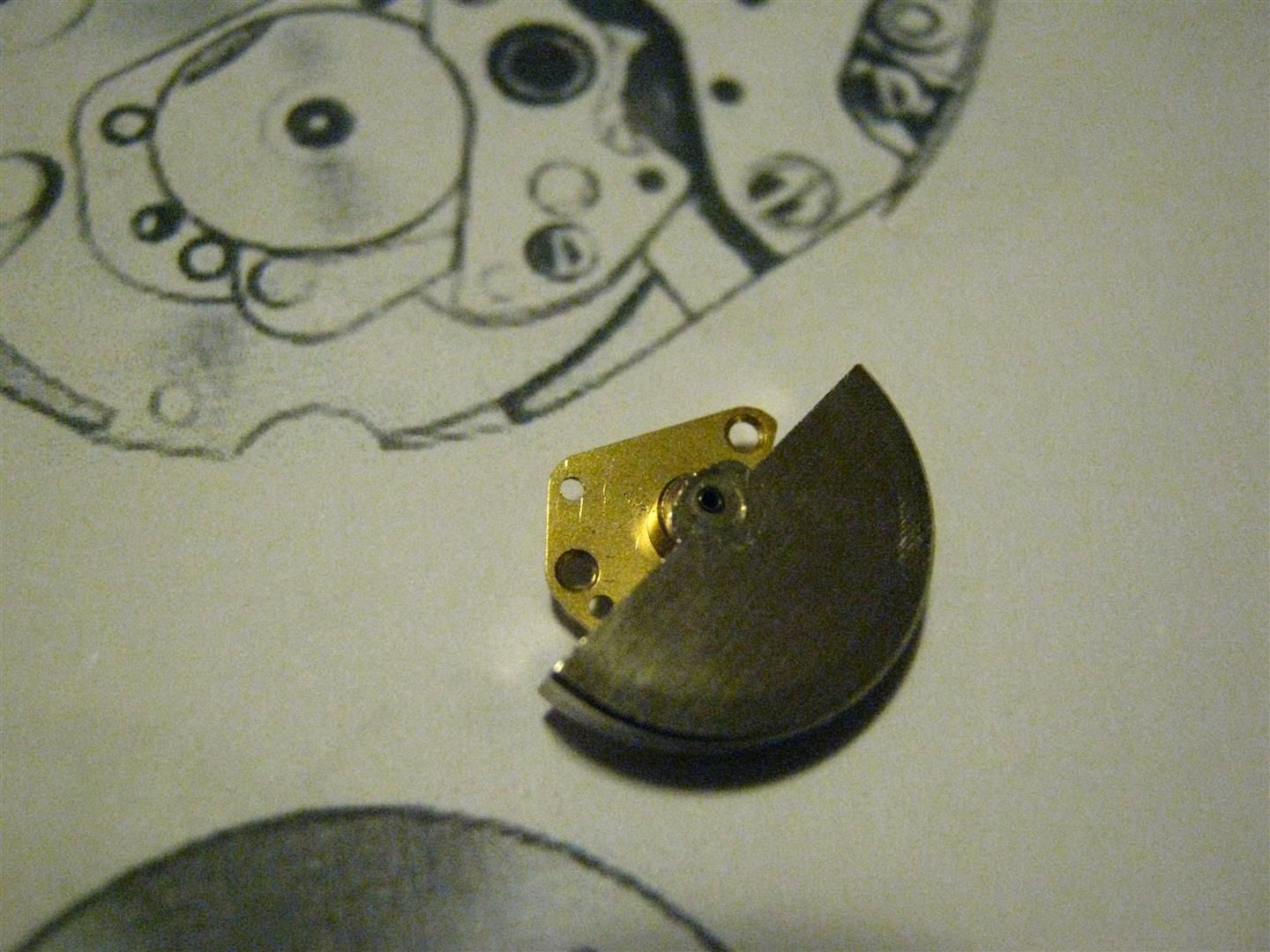

: Then remove the 1143/1 oscillating weight (the famous

: "microrotor") unscrewing its two 51131 screws (the

: second one is under the rotor):

:

:

: The microrotor with its bridge 1131 will appear like this (under

: the golden bridge there is the gear that allows the recharge):

:

:

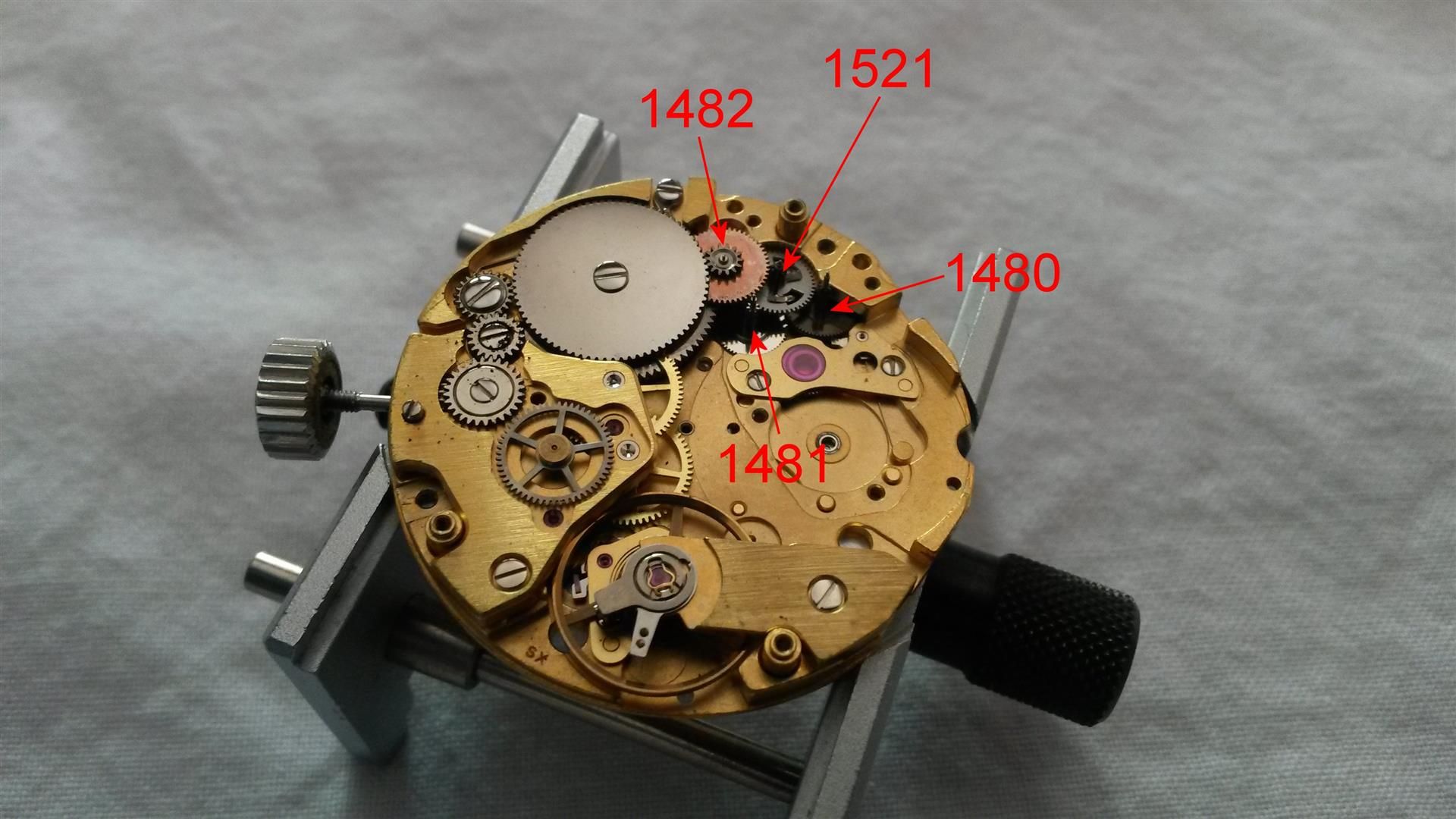

: Now remove the four wheels starting from the 1521 coupling wheel,

: then the 1482 driving gear for ratchet wheel, then the 1480

: winding up wheel and 1481 reduction gear (the last two are

: identical, no problem to store them together):

:

:

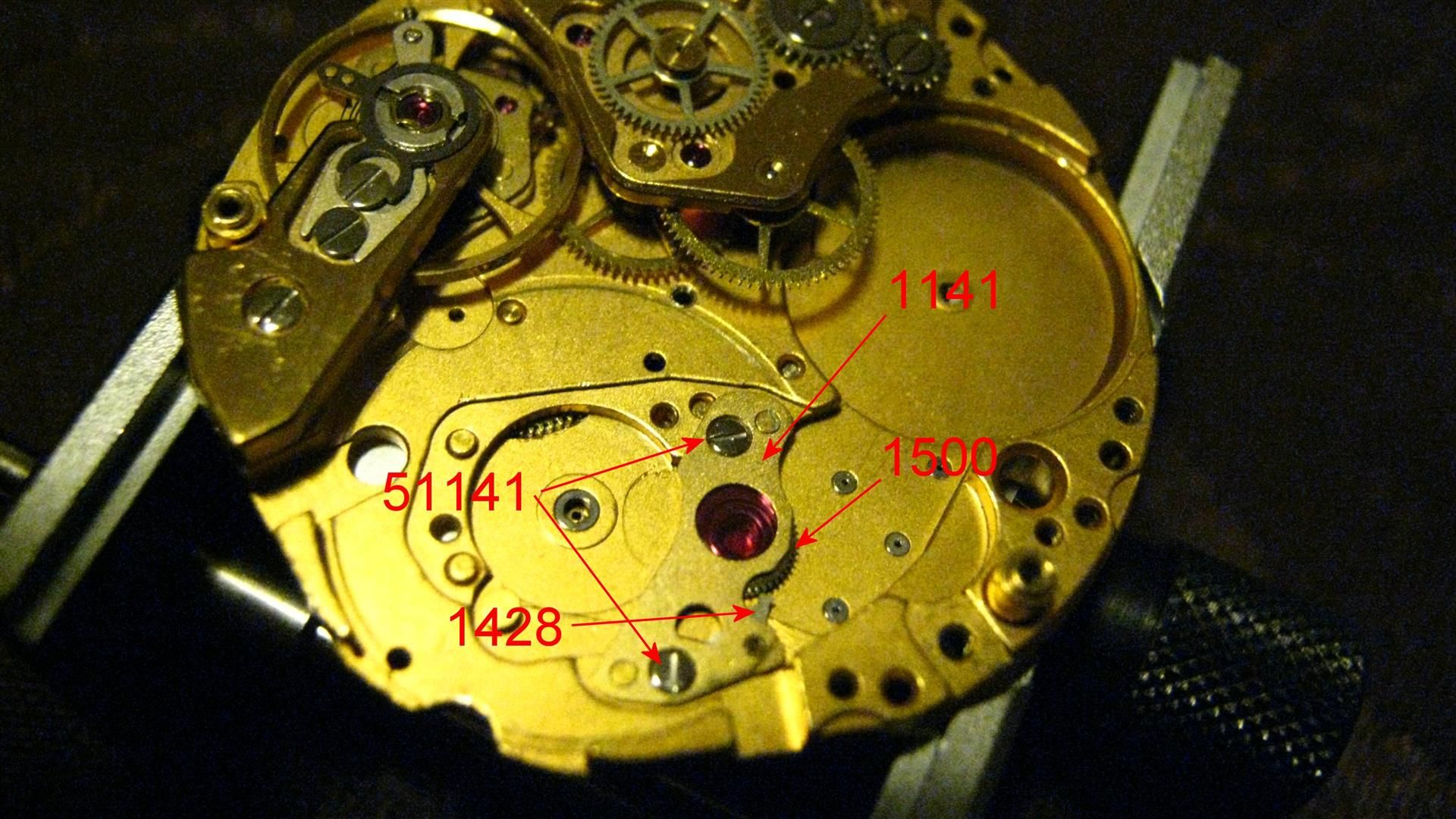

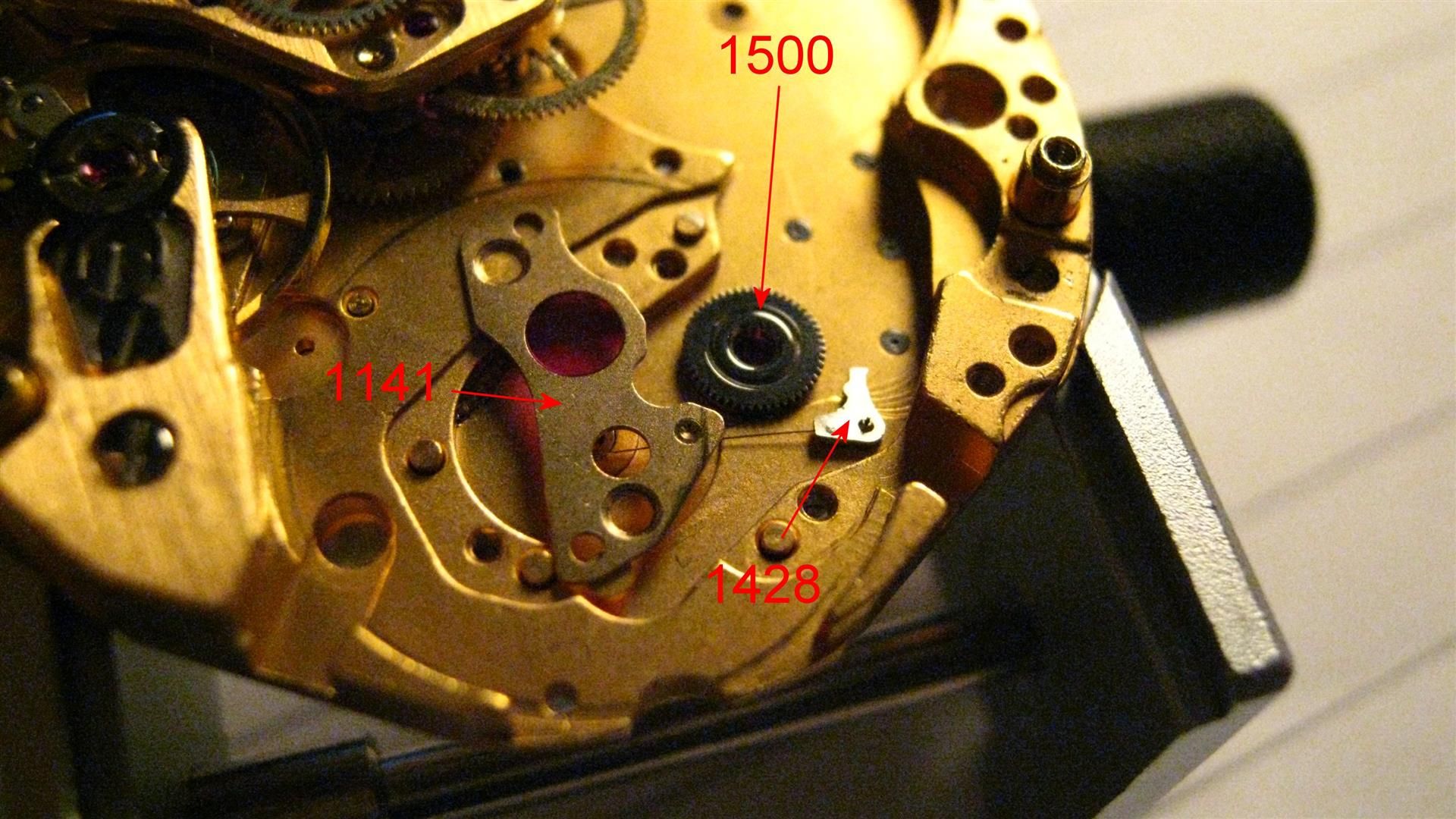

: Now it's the time for removing the 1141 lower bridge for automatic

: device, the 1500 wig-wag pinion and the delicate 1428 stop click

: (the one which allow that the mainspring doesn't unwind when

: recharged by the microrotor), obviously unscrewing the 51141

: screws:

:

:

:

:

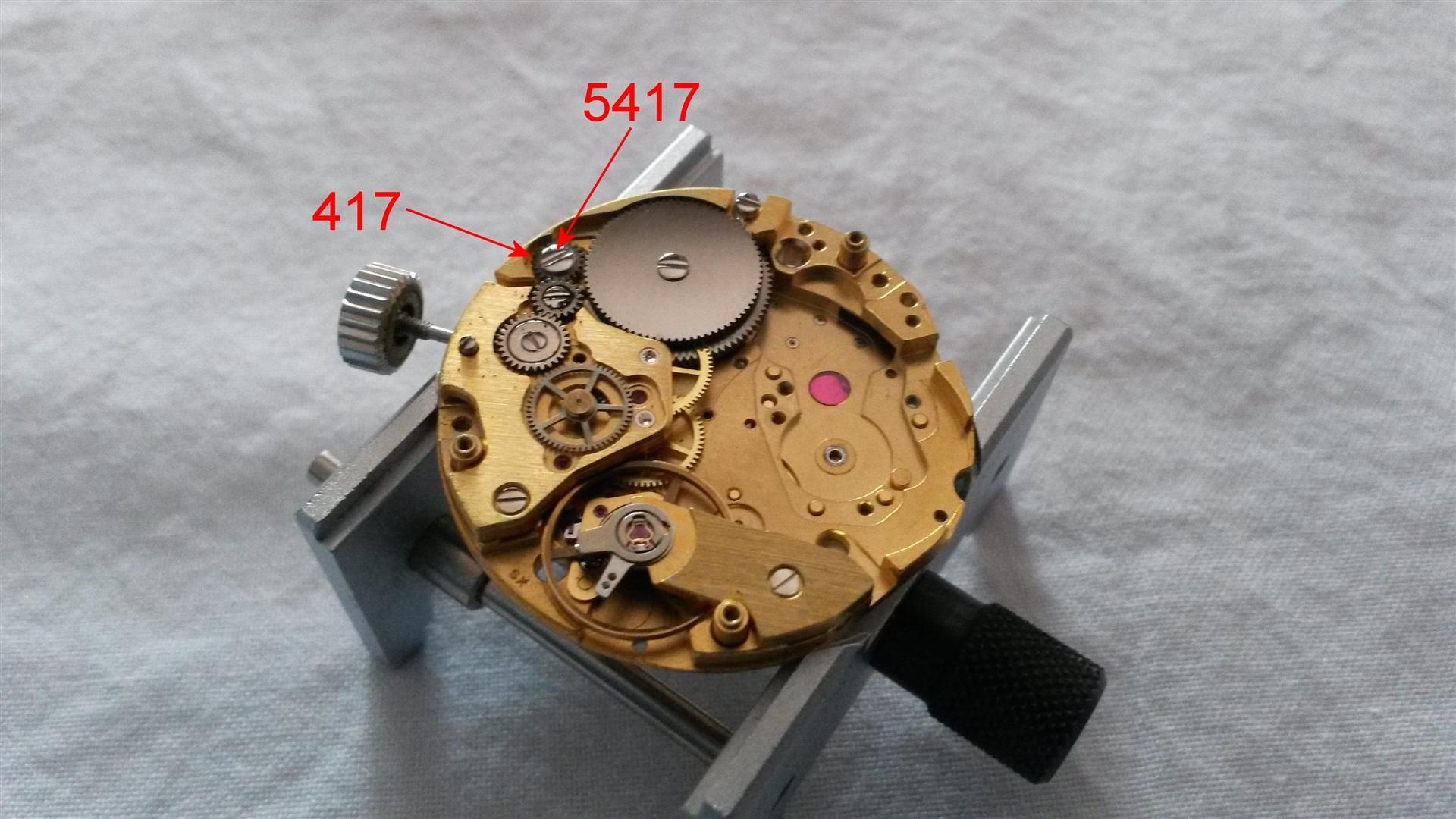

: Then remove the 417 intermediate ratchet wheel and its screw 5417:

:

:

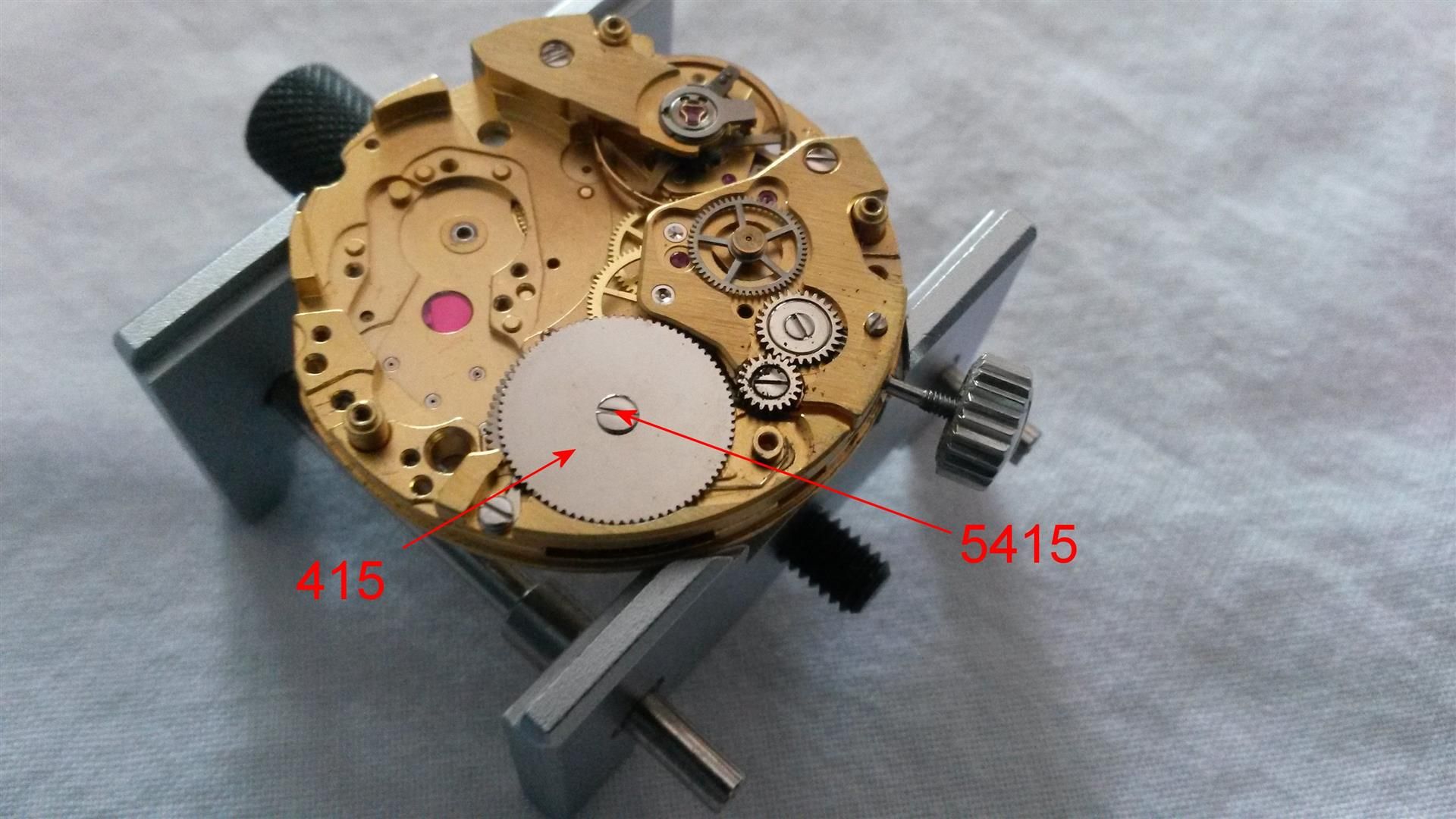

: Now remove the 415 ratchet wheel (after having unwinded the

: mainspring opening gently the 425 click) and its screw 5415:

:

:

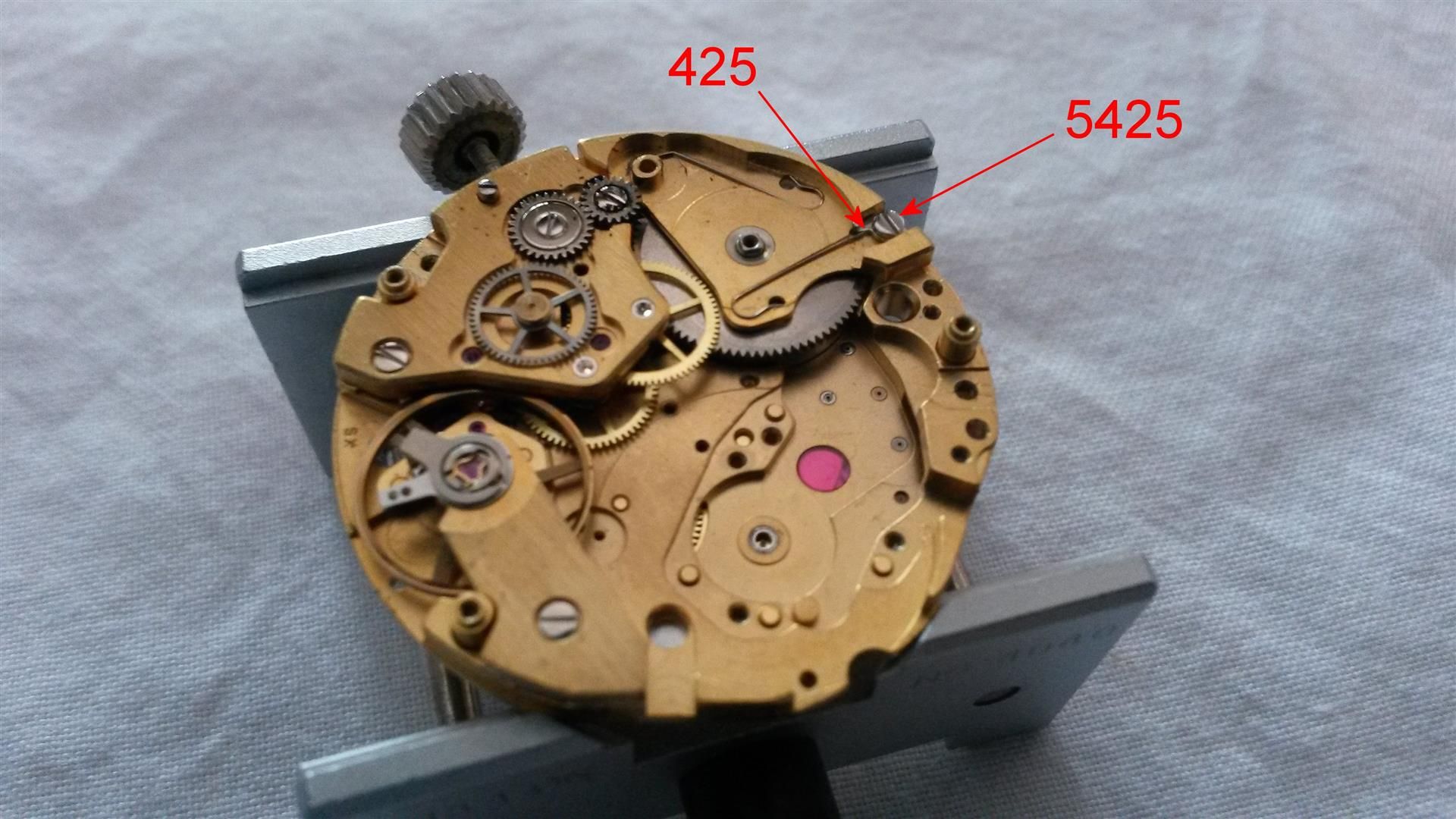

: Now remove the 425 click and its screw 5425:

:

:

: Remove the 105 barrel bridge BUT leave in place the two springs 430

: (click spring) and 523 (setting wheel spring), otherwise they

: will squeeze into the hyperspace (and you will have a serious

: problem :-) ):

:

:

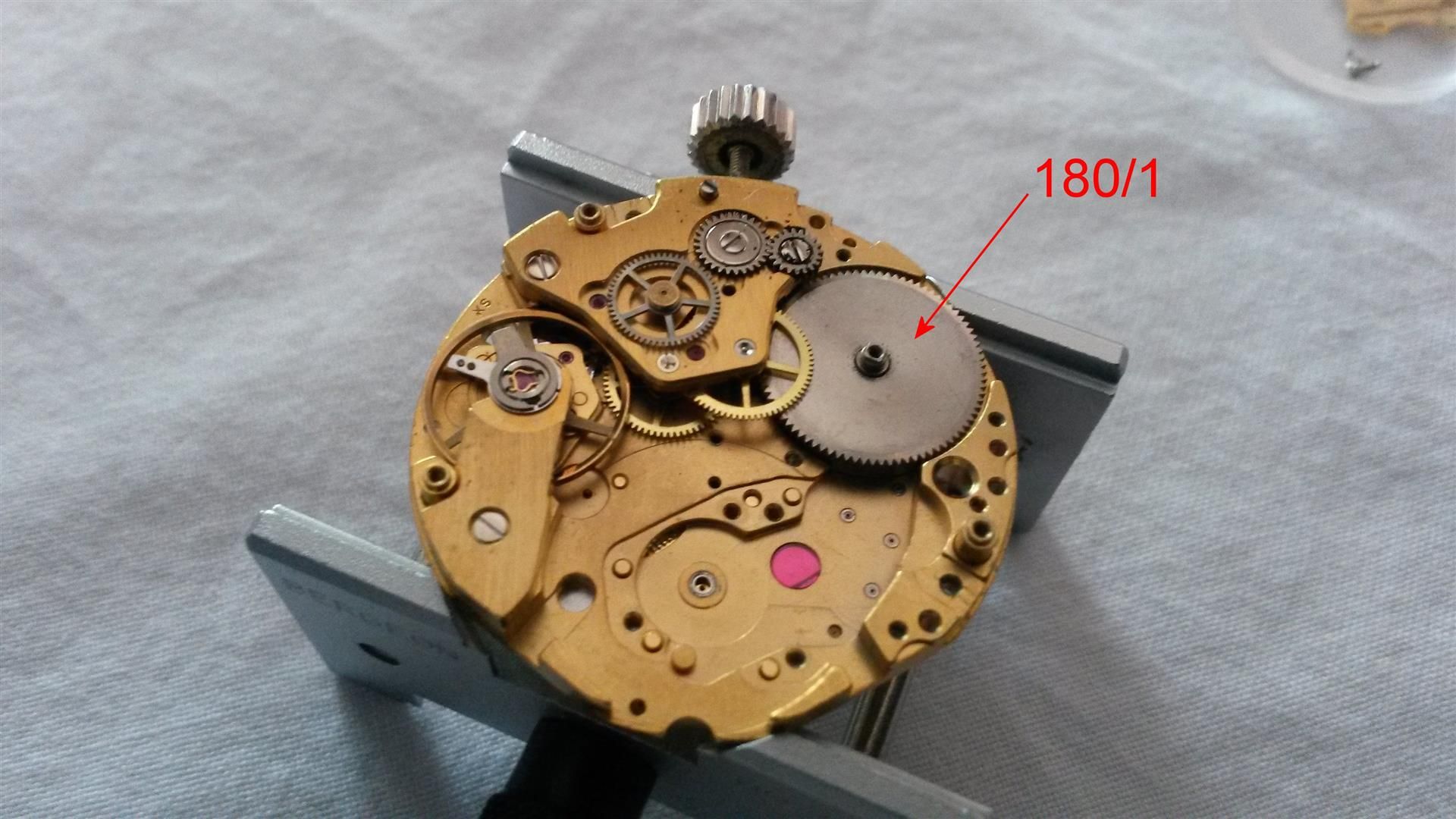

: Remove the 180/1 mainspring's barrel pulling it up at the opposite

: side respect the 200/1 large driving wheel:

:

:

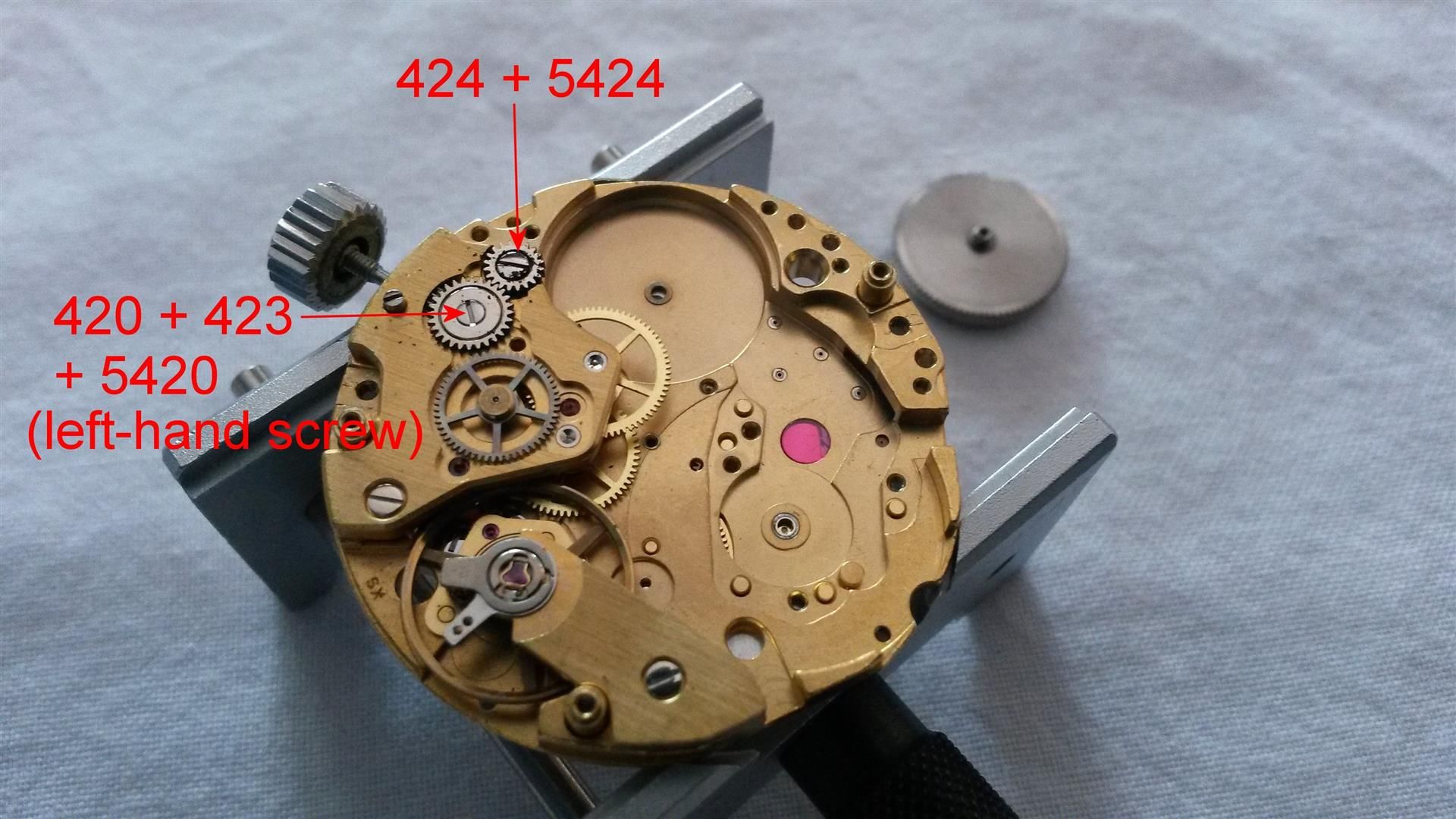

: Remove the 424 intermediate crown wheel and its screw 5424, then

: the 420 (core) + 423 wheel taking care that its 5420 screw is a

: LEFT-HANDED screw (you must "normally screw" to

: unscrew it):

:

:

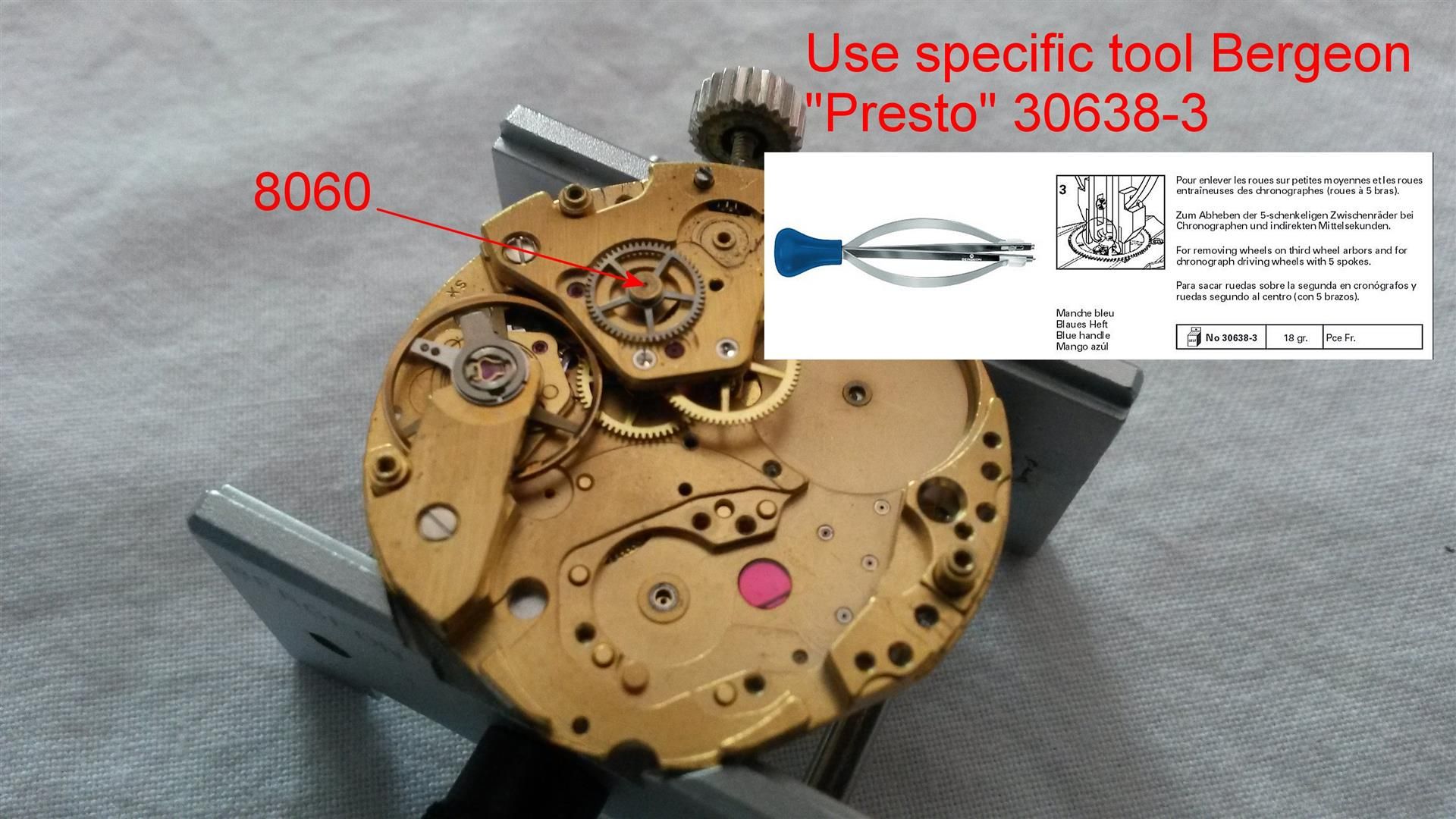

: remove the 8060 driving wheel using the apposite Bergeon tool:

:

:

: now the 110 train wheel bridge and its screw 5110 (if, after

: uncasing the movement, you put again the stem w crown you must

: re-open its screw 5443 by 1.5 turns and pulling out the stem):

:

:

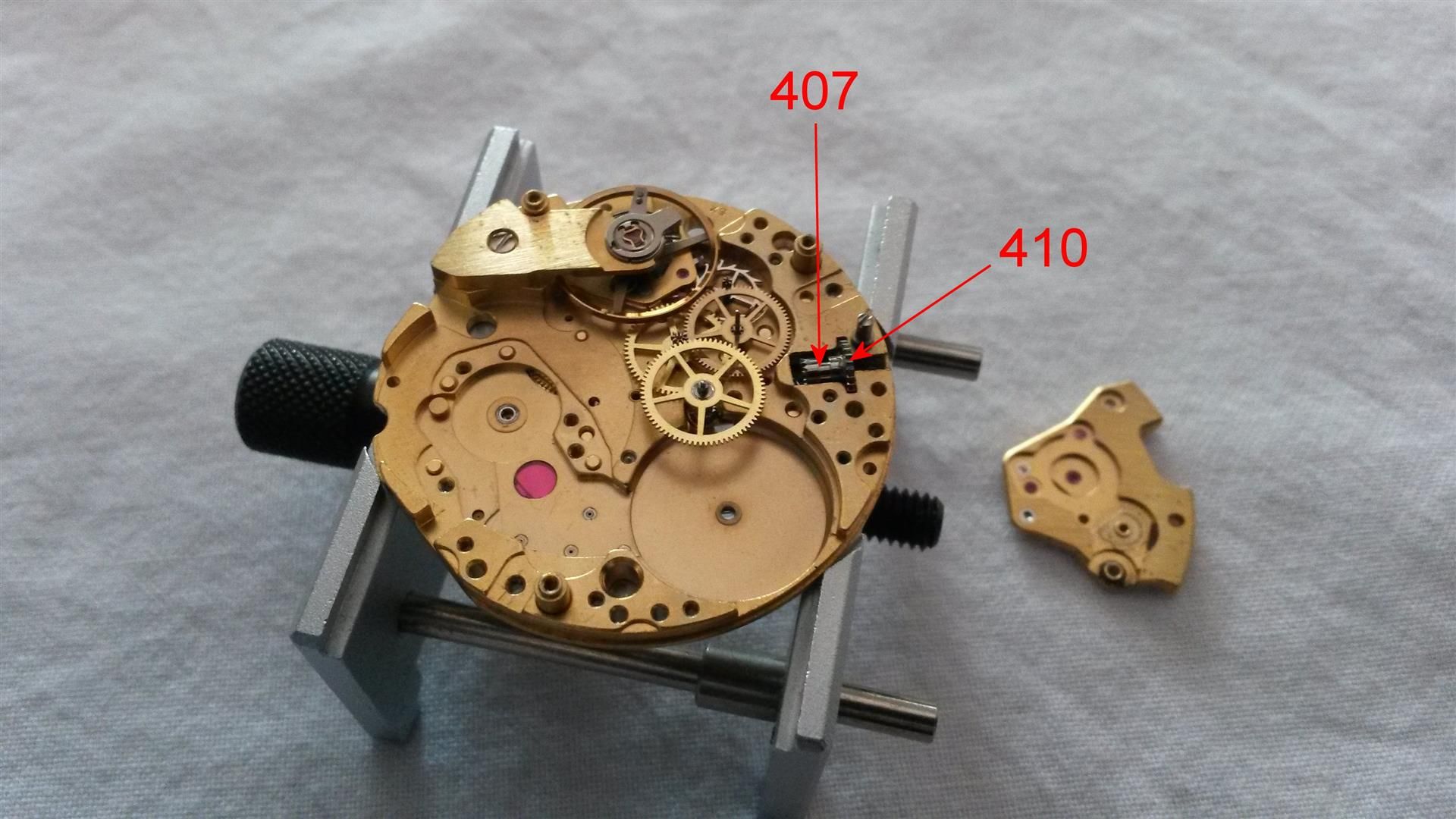

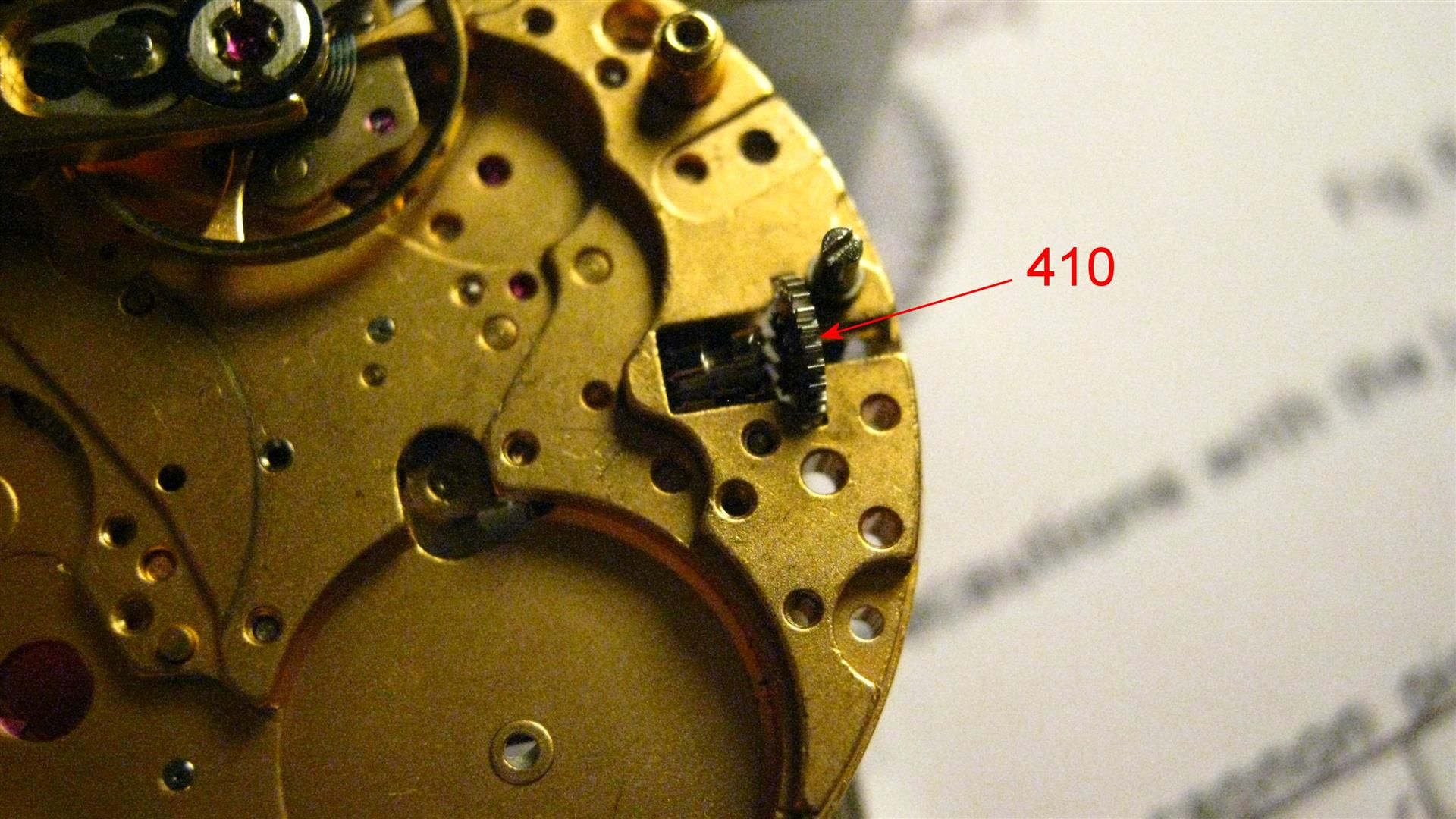

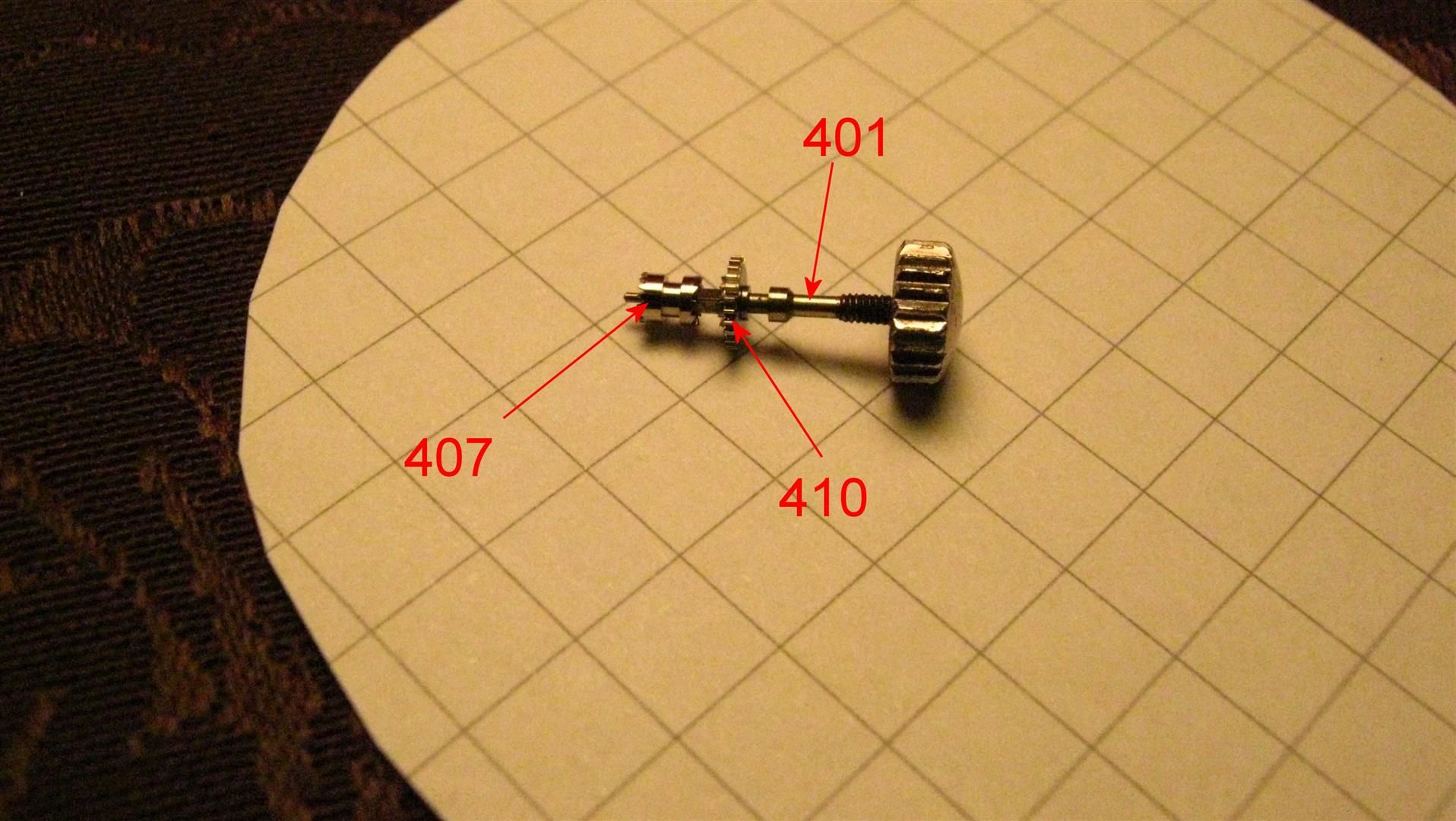

: now the 407 clutch wheel and 410 winding pinion:

:

:

:

:

:

:

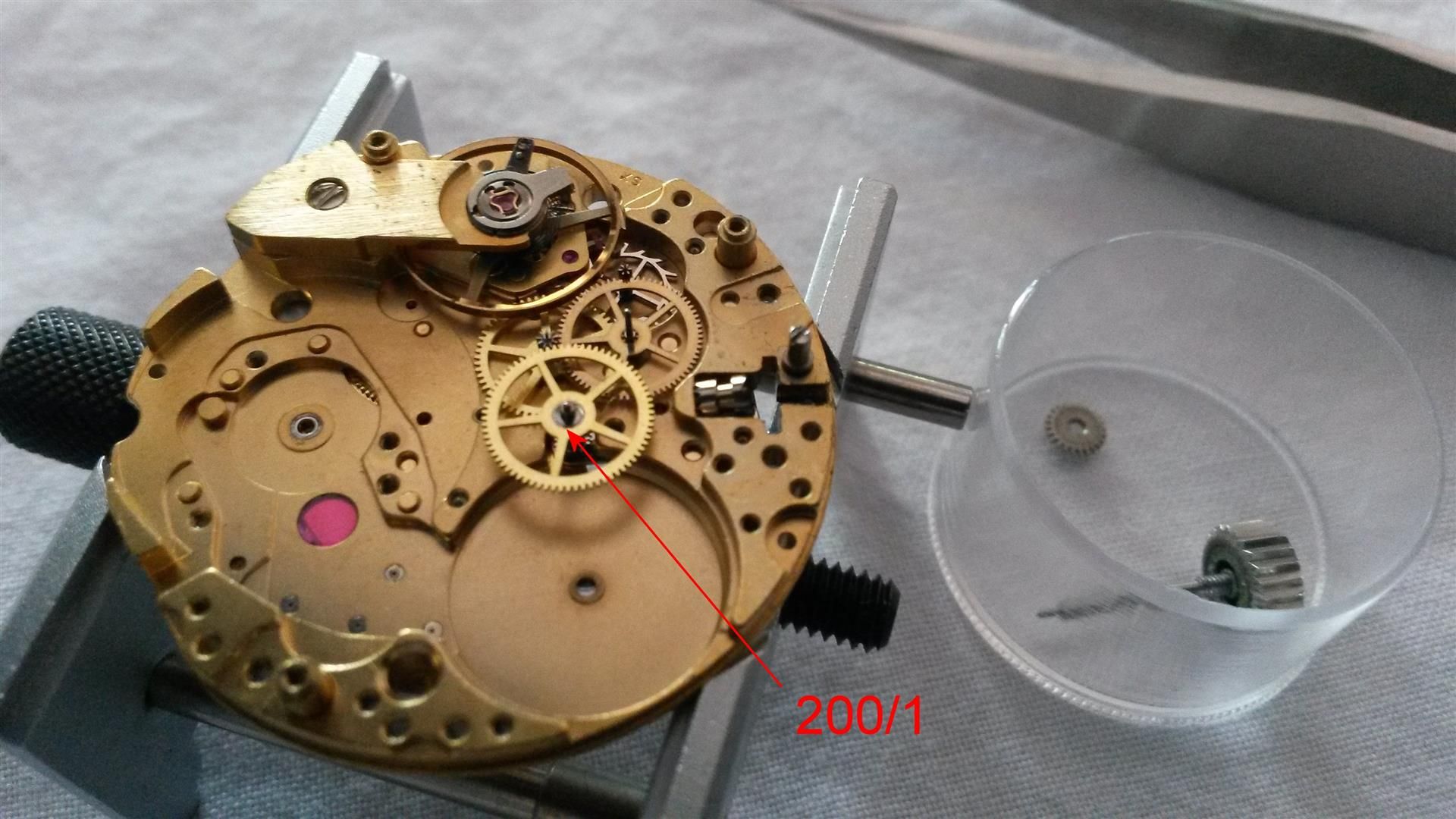

: now the 200/1 large driving wheel with cannon pinion:

:

:

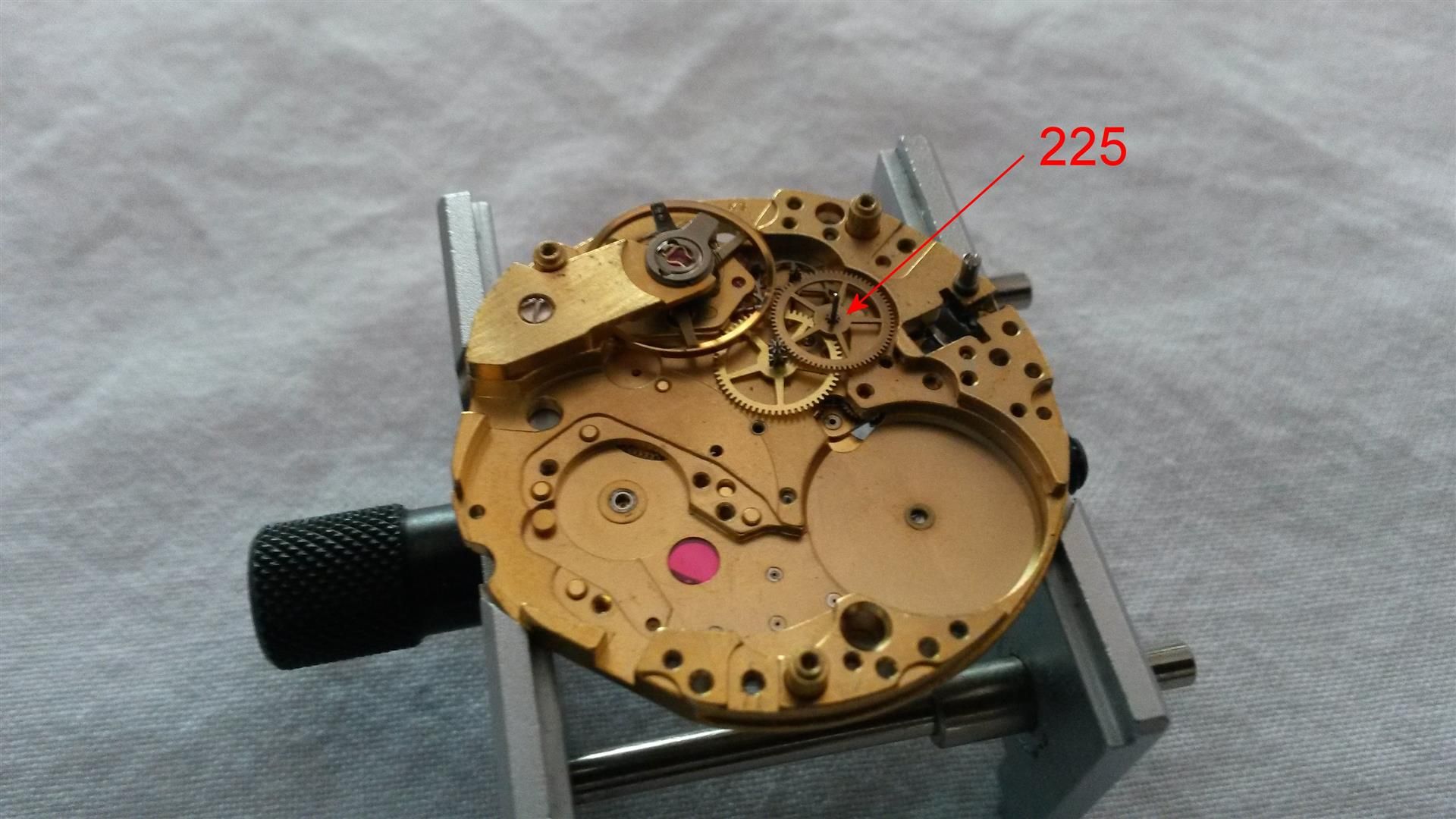

: the 225 fourth wheel (in the Cal15 supports the small seconds hand

: at 10 'clock):

:

:

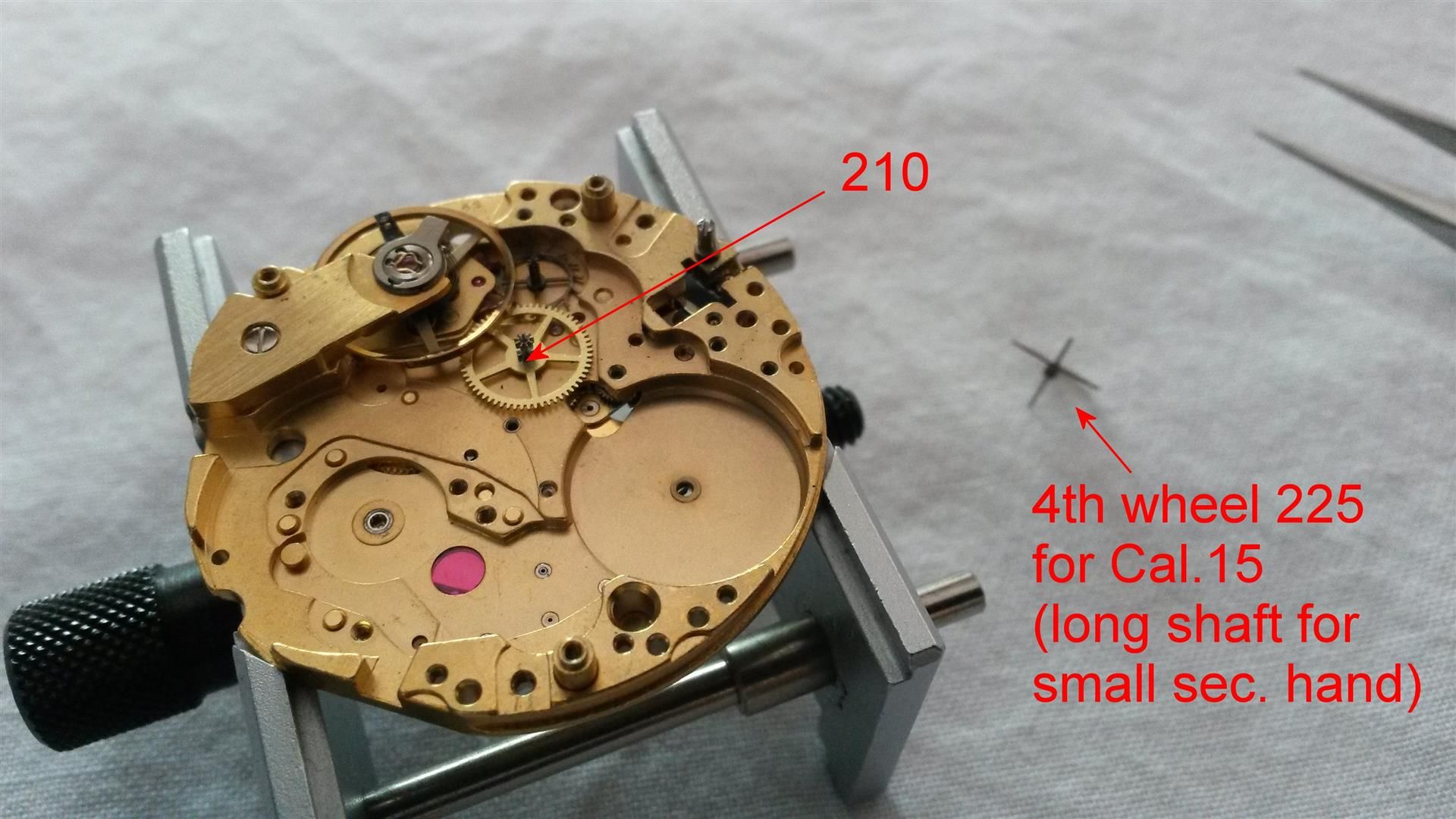

: the 210 third wheel:

:

:

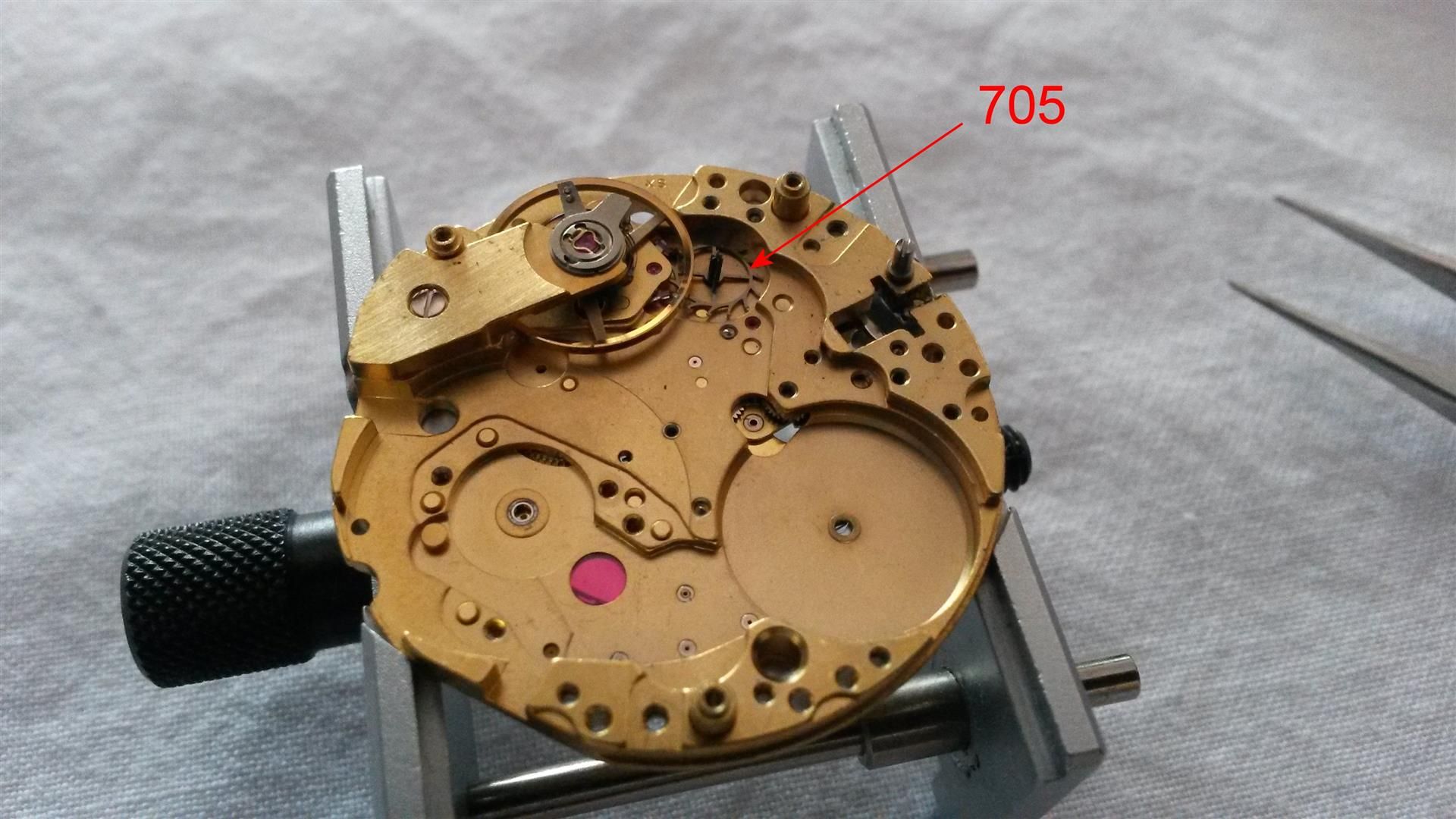

: and finally the 705 escape wheel:

:

:

: and you will have the main plate free from any wheel (balance wheel

: apart):

:

:

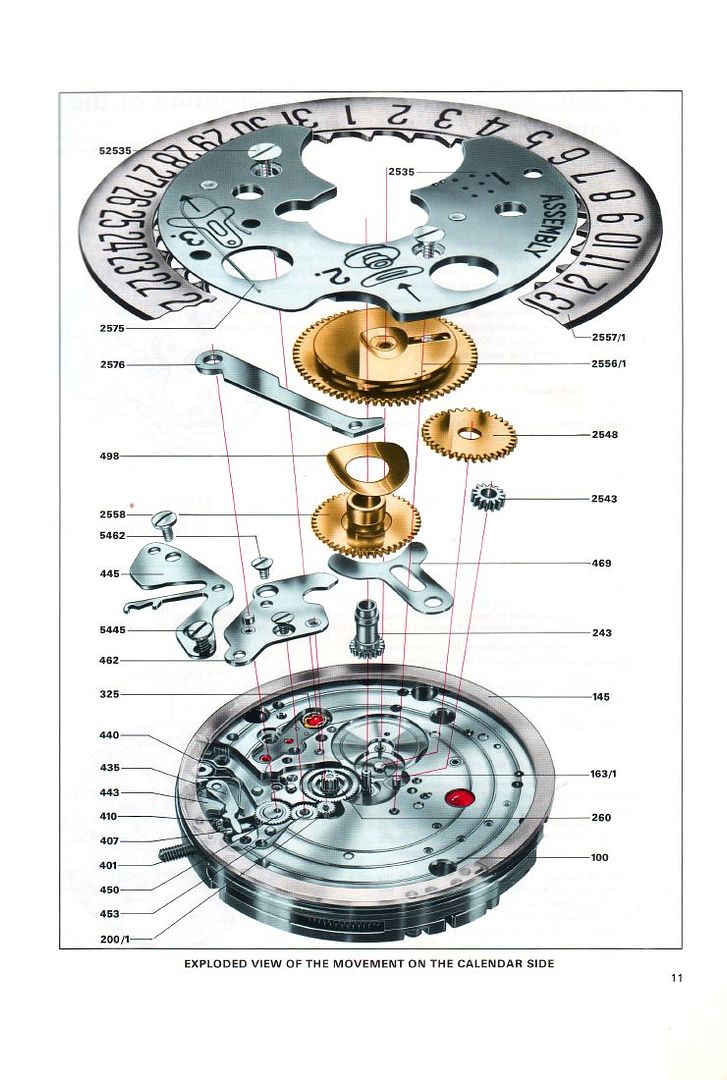

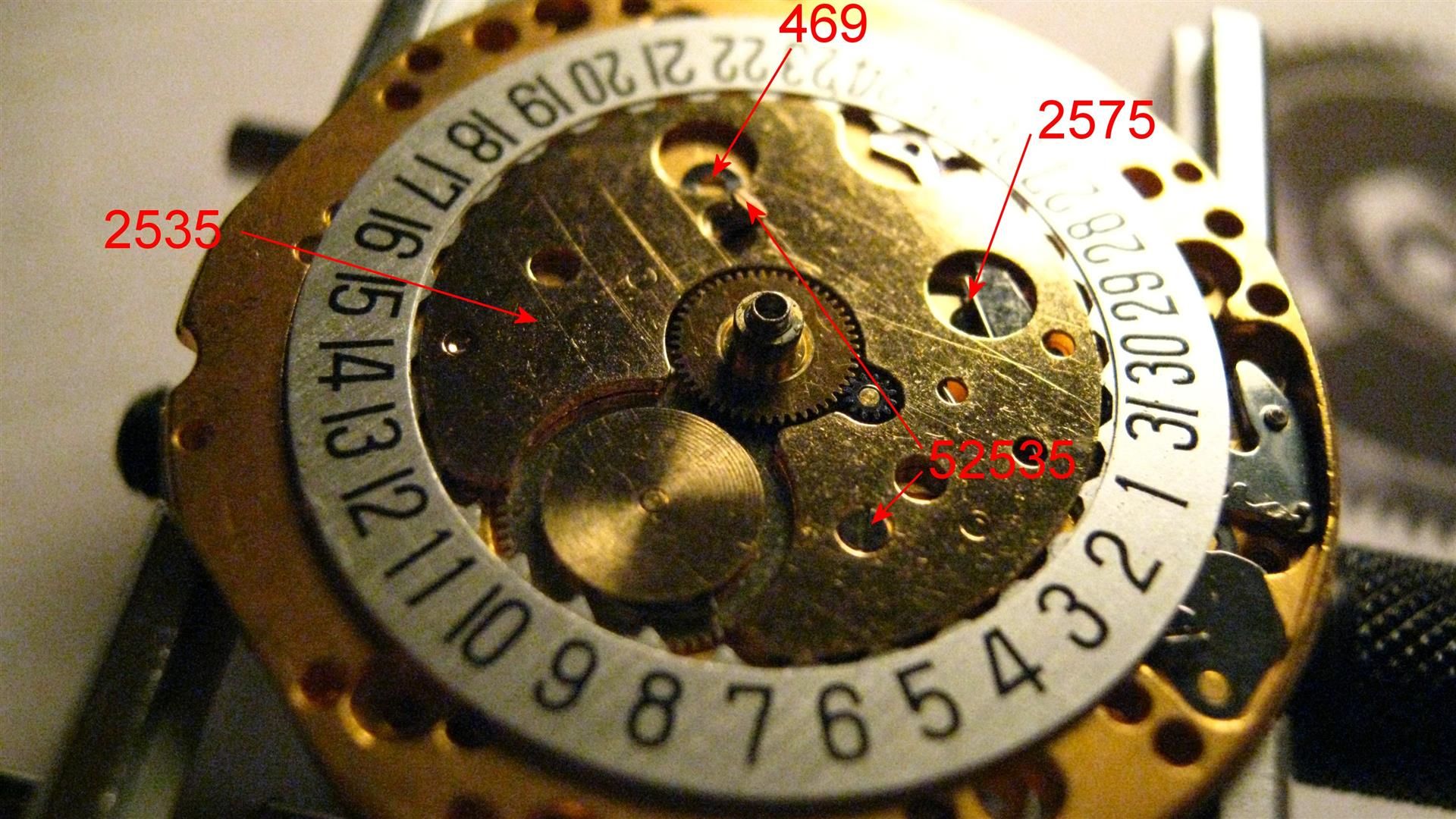

: Turn the movement on the dial side and start disassembling it.

: First unscrew the 52535 ones and pull-up gently the 2535 date

: indicator guard (take care not to damage the date disc):

:

:

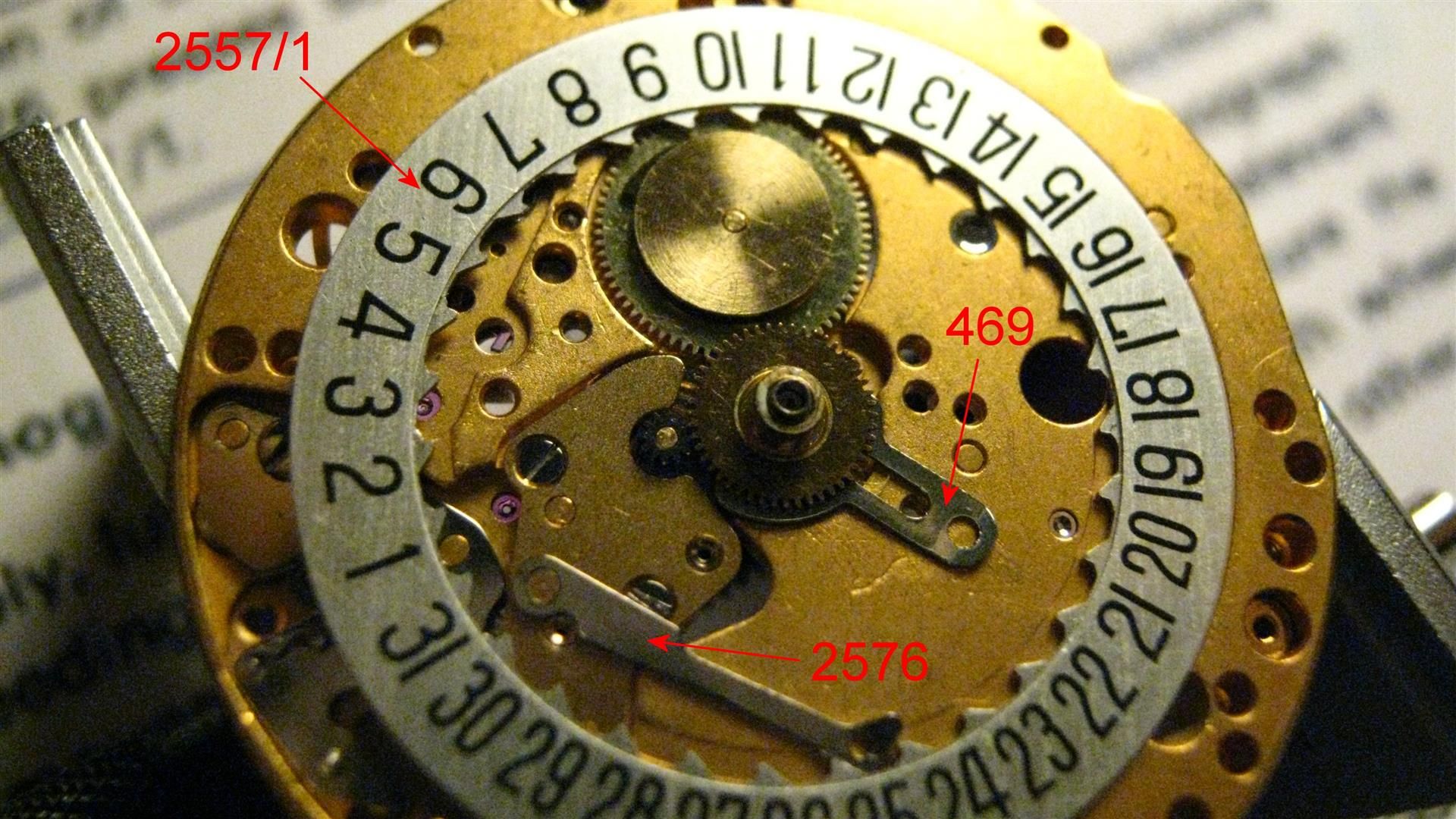

: now remove the 2557/1 date indicator, the 469 hour wheel guard and

: the 2576 date jumper (notice that its 2575 spring will remain

: attached to the 2535 date indicator guard):

:

:

: now pull-up the 2558 double-toothing hour wheel (supports the hour

: hand) and the 243 cannon pinion (supports the minute hand):

:

:

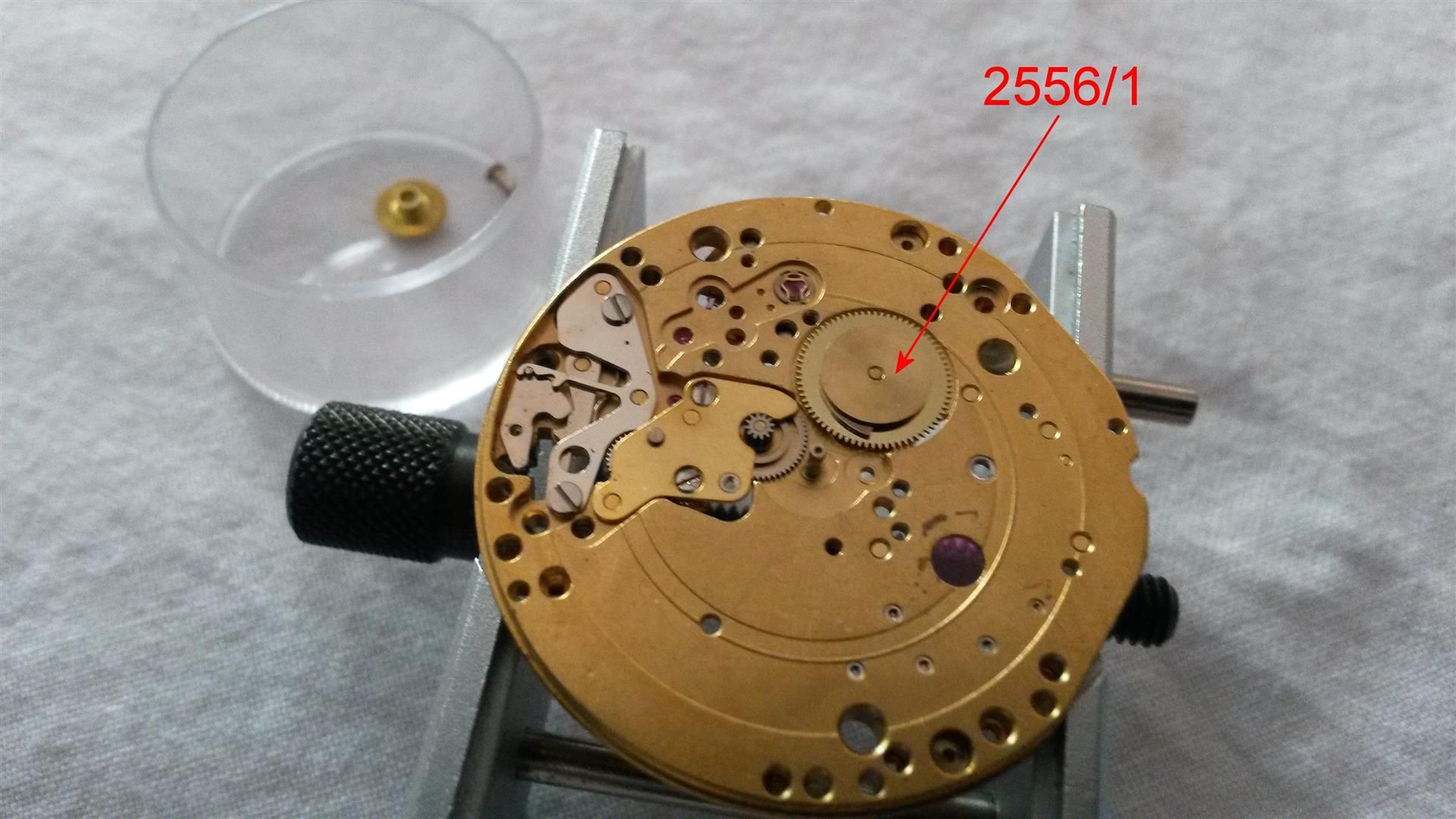

: now the 2556/1 date indicator driving wheel:

:

:

: remove the 462 minute work cock and its screws 5462:

:

:

: then the 260 minute wheel:

:

:

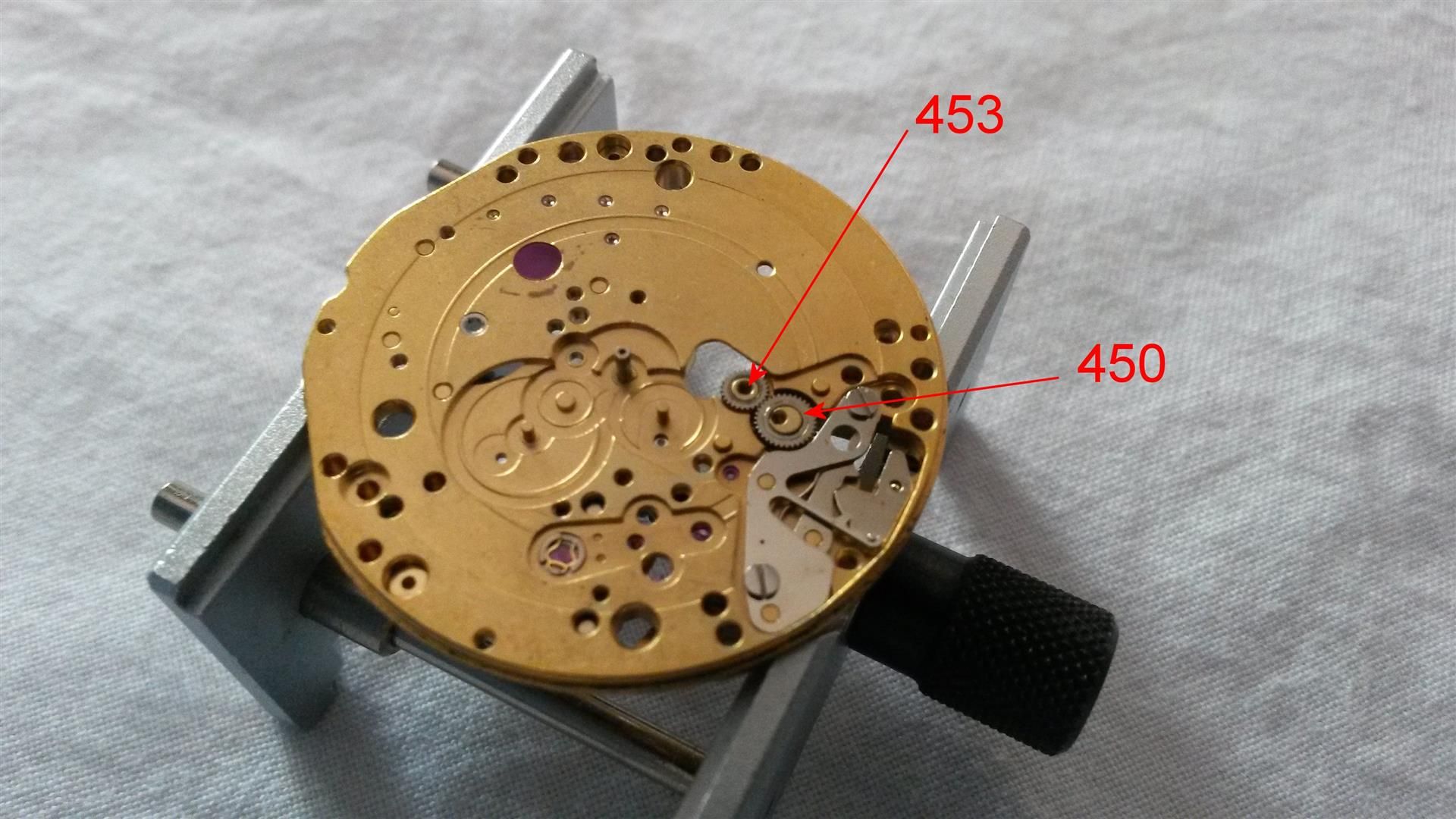

: the 453 additional setting wheel and the 450 double setting wheel:

:

:

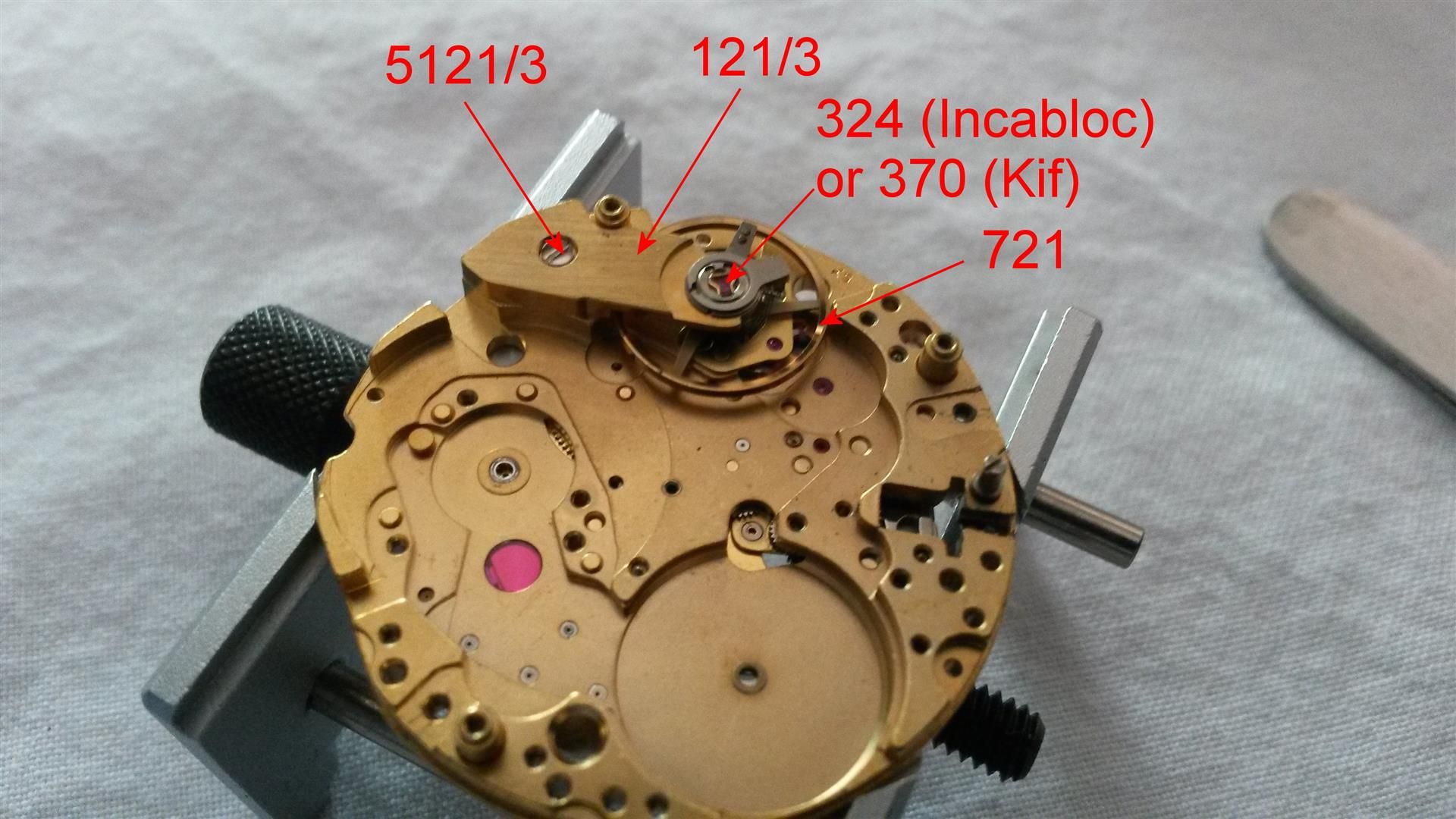

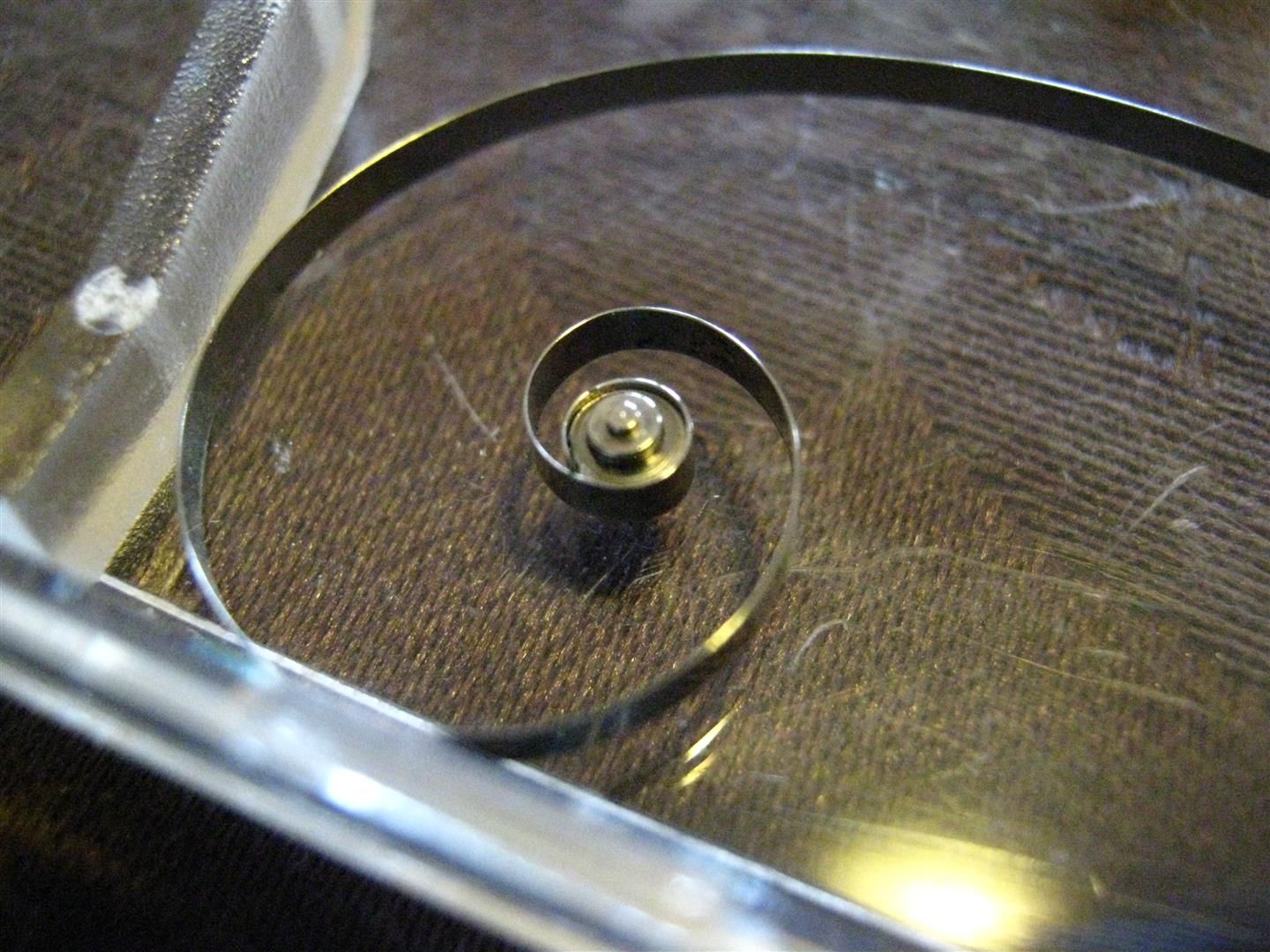

: turn the movement again and let's go with the 721 balance wheel and

: its 121/3 bridge (correct name is balance cock for stud holder

: and shock-protecting device), then open the Incabloc (for

: Cal11/12/14) or Kif (for cal15) golden spring (lyra shaped) and

: remove the 324 Incabloc upper jewel or 370 Kif upper jewel

: (first time I did I lost it sqeezing out from the pliers, then

: understood that a small ball of Rodico with a toothpicker can

: help a lot :-) ):

:

:

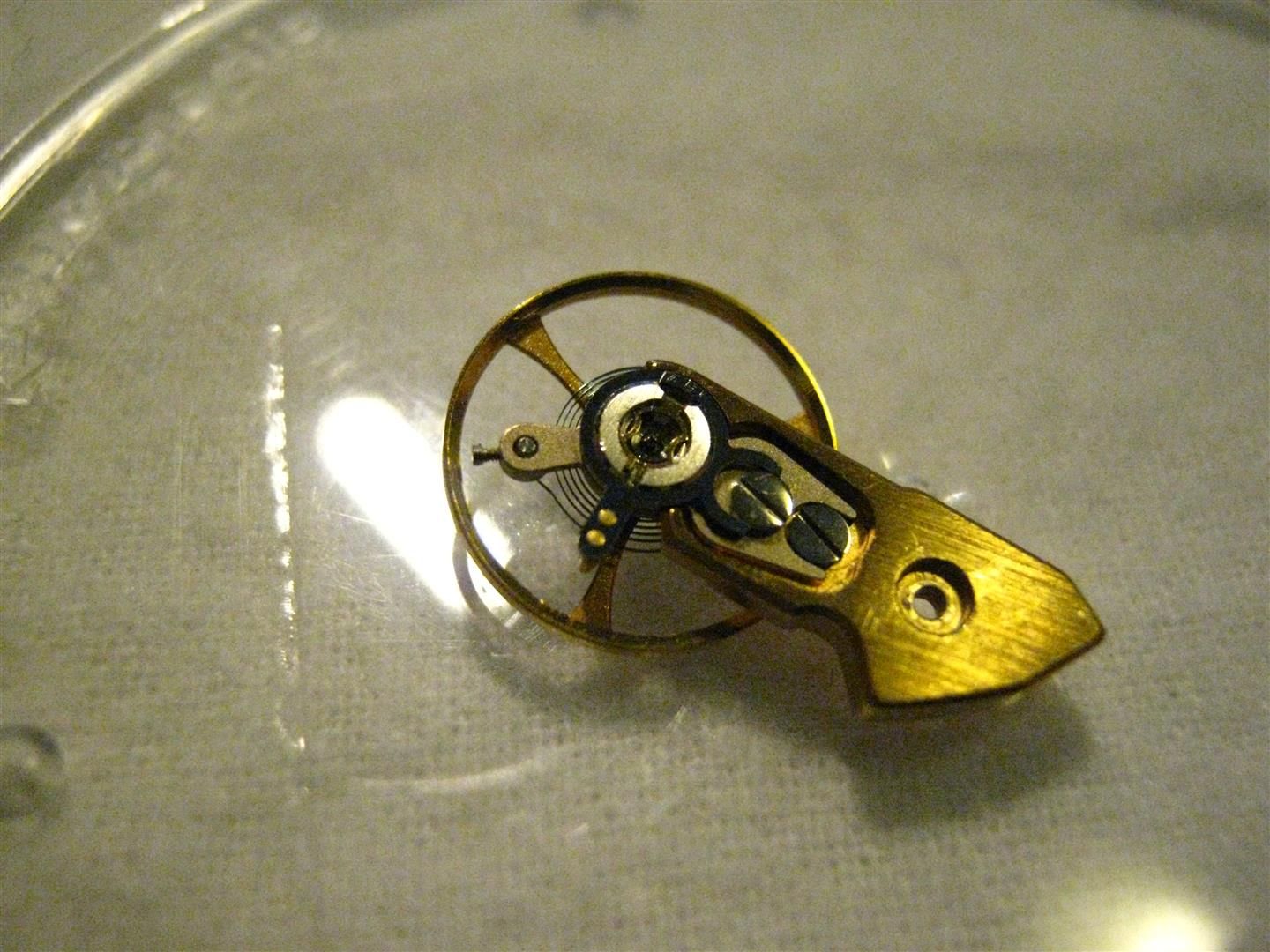

: close the Incabloc (or Kif) spring to avoid losing it and handle

: the balance wheel with care, its hairspring is the more delicate

: part of the watch:

:

:

:

:

:

:

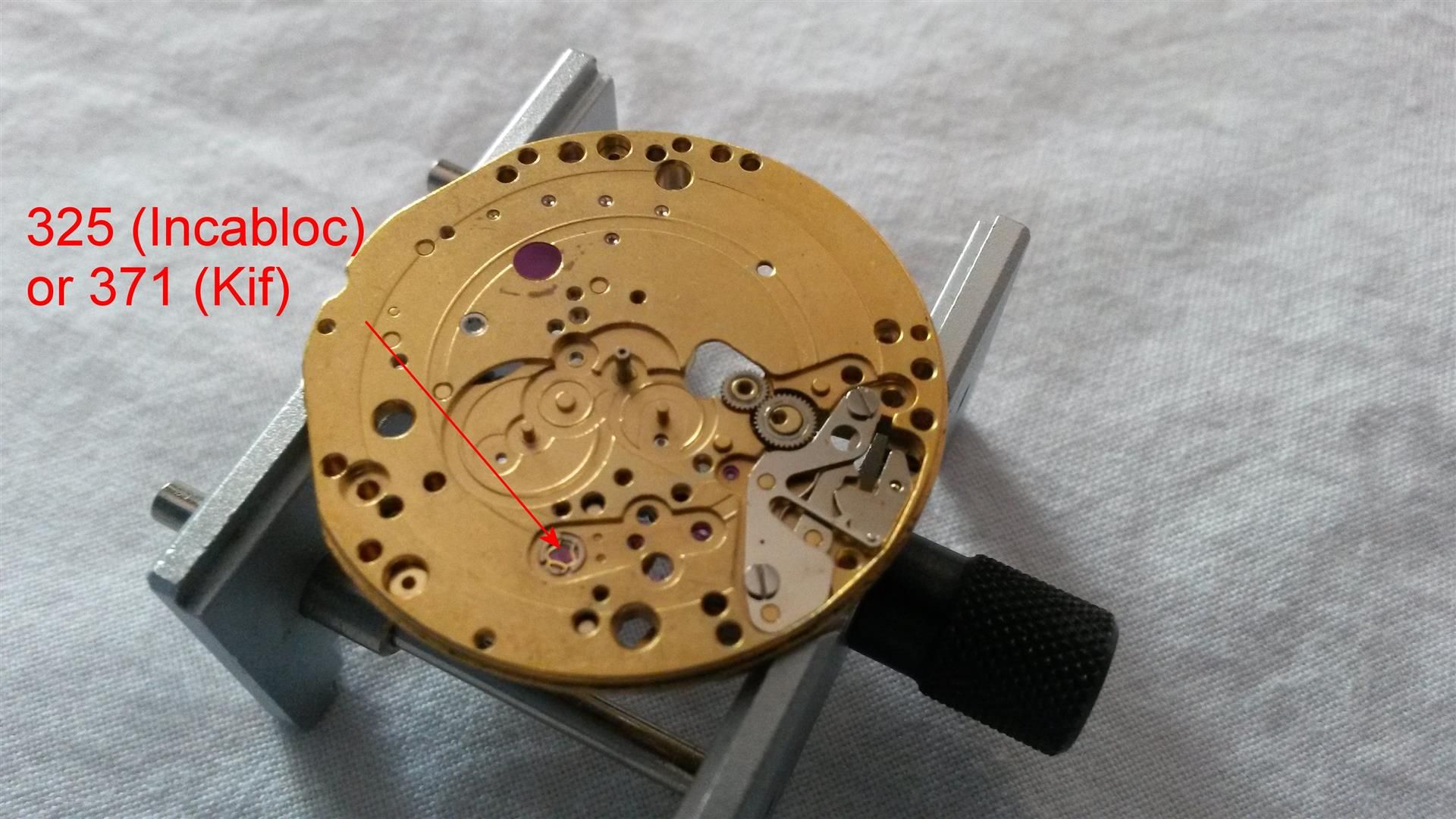

: make the same thing on the dial side removing the 325 Incabloc

: lower jewel from its case (or 371 for cal15):

:

:

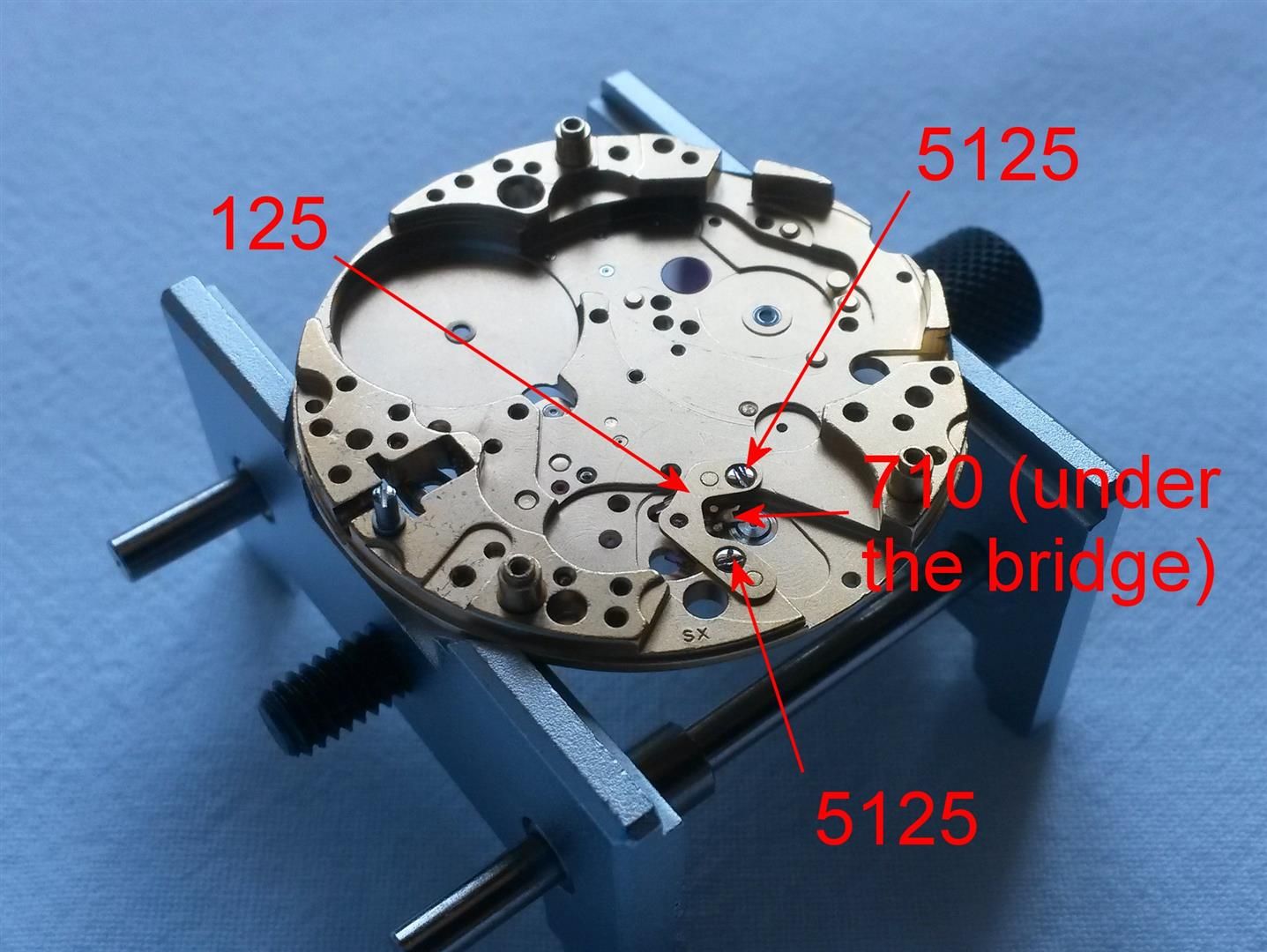

: then the 125 pallet cock (unscrew the two 5125 ones) and the 710

: pallet fork:

:

:

: if you need to service the mainspring (highly recommended) you must

: open the barrel pushing it on a hard surface, take care that the

: mainspring will squeeze out so do it gently:

:

:

: then remove the 195 barrel arbor:

:

:

: and you will have the mainspring ready to wash and putting back

: again using the specific Bergeon tool (mainspring winder):

:

:

: this is my Monza completely disassembled, ready to wash and to be

: oiled and reassembled (but this is another long story):

:

:

: Before leaving you all I want to thank the person (pro watchmaker)

: who helped me a lot every time I found a problem or had an

: undocumented step to do: you know who you are, and without your

: help I would never did it by myself, so thank you from the deep

: of my heart ;-)

: Hope you will have enjoyed if you arrived until here.

: Cheers.

: Gianluca

| Chronocentric and zOwie site design and contents (c) Copyright 1998-2005, Derek Ziglar; Copyright 2005-2008, Jeffrey M. Stein. All rights reserved. Use of this web site constitutes acceptance of the terms of use. | CONTACT | TERMS OF USE | TRANSLATE |