| Informational Websites | ChronoMaddox -- the legacy of Chuck Maddox | OnTheDash -- vintage Heuer website | Zowie -- Omega information |

| Discussion Forums | ChronoMaddox Forum | Heuer Forum | Omega Forum |

| Counterfeit Watchers | ChronoTools Forum | ChronoTrader Forum |

|

|

The largest independent, non-commercial, consumer-oriented resource on the Internet for owners, collectors and enthusiasts of fine wristwatches. Online since 1998. | |||||||

|

||||||||

|

||||||||

|

Vintage Heuer Discussion Forum

The place for discussing 1930-1985 Heuer wristwatches, chronographs and dash-mounted timepieces. Online since May 2003. | ||||||

| |||||||

| |||||||

Hi all,

after my first post (I really thank you all for your affection, I didn’t expect such a reaction) some people asked me to illustrate also the remaining steps in order to service a Chronomatic movement, so in this post I will try to rearrange my little experience to explain how to clean the single parts before reassembling them.

But please, don’t take my next words as the “Holy Bible”, I repeat this is only what I self-learned experiencing with the few watches I serviced so far, I never attended a watchmaking course (only read some technical documents and lurked the web on some fora), so for sure there will be a different and better or faster way to do something I will illustrate, be patient.

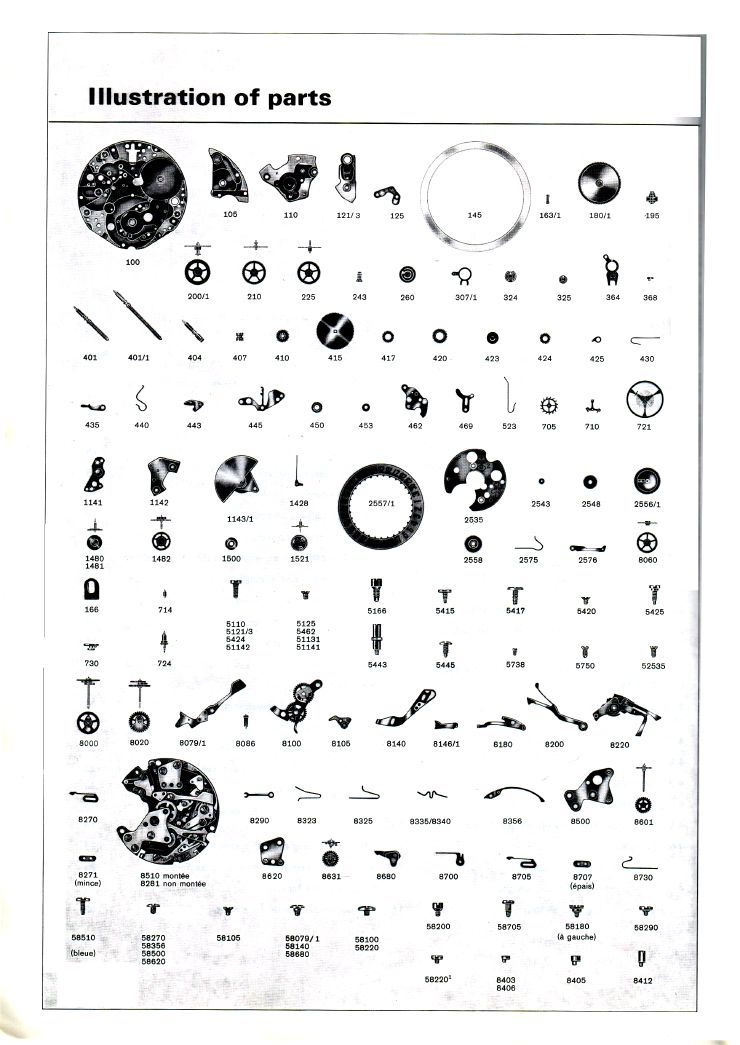

The following is a page taken from the service manual illustrating all the parts you will have to clean (the parts in the lower section will be assembled together to form the chronograph module, that I don't dismantle before washing):

Only exceptions (that is parts I usually don’t clean - but someone could do, don't know) are:

a) the date disc 2557/1 (the cleaning solution could remove the numbers);

b) the date indicator driving wheel 2556/1 (is not a simple wheel but is an assembly and cannot be disassembled, so I only clean the shaft hole with the Rodico);

c) the dial rest 145 (is made of plastic material, better to wash with soap);

d) eventually the large driving wheel 200/1 if you don’t plan to remove or replace its cannon pinion (otherwise, if you wash it, you will have to re-oil the arbour of the driving wheel where the pinion fits, so if you don't wash it at least clean the teeth and the pivot ends with Rodico to remove the old oil).

Before starting I have few recommendations (put on the paper in sparse order, as they came in my mind), that are valid in general working on watches (not only to clean the parts):

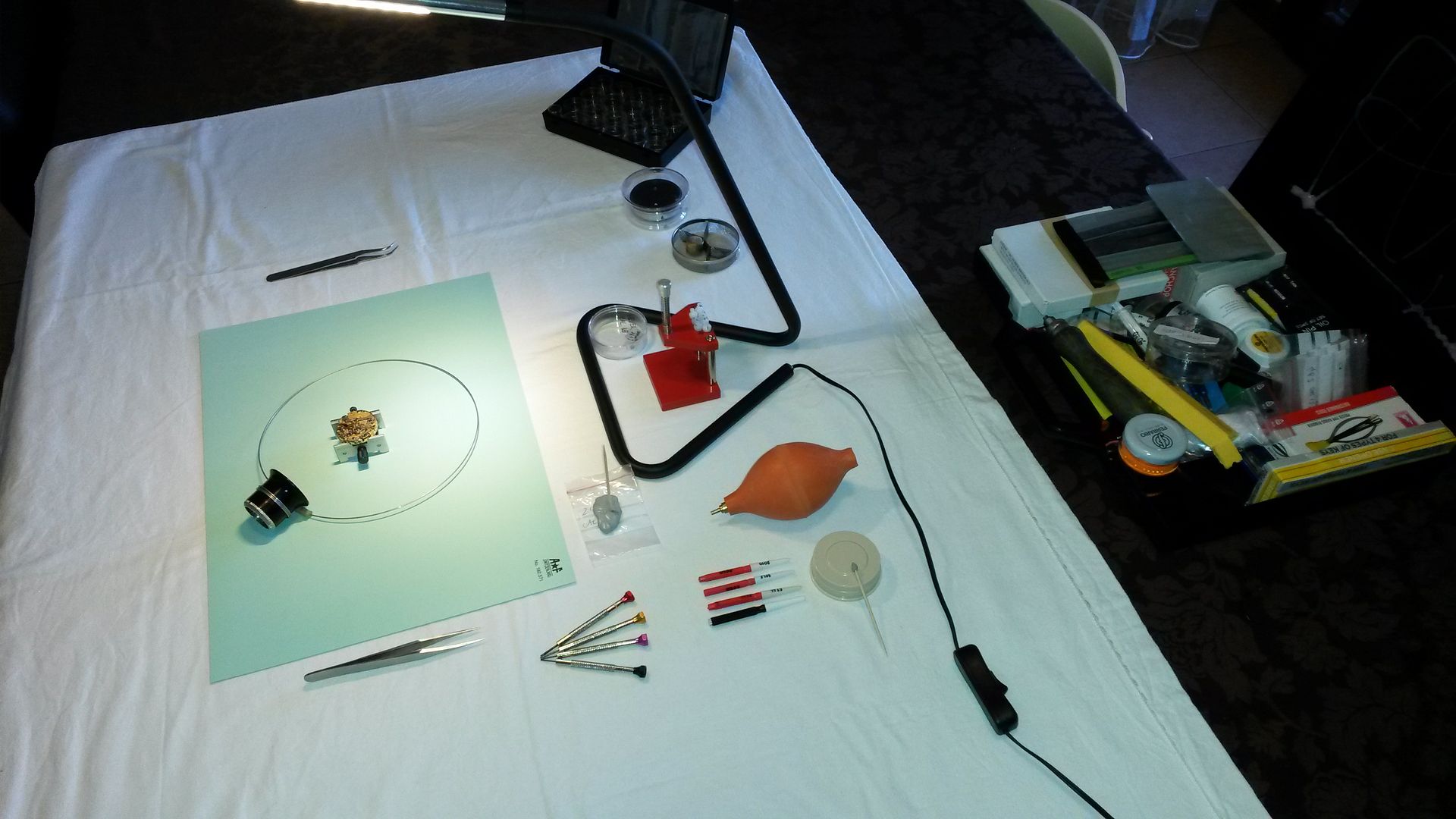

a) Before starting the job be sure to have a work bench clean and free from extraneous objects. As I live in a small flat and I don’t have a room to dedicate to my hobby, when I work on my watches I use the living-room table after having free it from any object and after putting on it a white and clean undersheet.

In fact, the first time I tried to remove the jewel caps from the Incabloc cage I was working on a brown towel covering the glass table top, the jewel cap squeezed out from the tweezers and I can ensure you have no hope to find a dark-red coloured stone small like a pin-head on a brown table :-(

b) Do not touch the parts with naked fingers, always use rubber gloves (especially after having cleaned the movement parts) or finger cots (personally I hate them and prefer the surgical white thin gloves) in order to keep the parts clean from the grease, the sweat and the skin particles that naturally our hands could have;

c) Work on watches only if you are fresh and calm and, above all, without any distraction around (so no children playing around, no wife/girlfriend complaining around), working on your watch must be an unstressful pleasure but needs concentration;

d) Prepare all the tools you will need during the job session BEFORE starting the session and put them in order around you;

e) Work with a white and uniform light (the white undersheet on the table will help to have an uniform and white illumination), when I work overnight (not ideal and in contrast with point c) but…) I use a cheap LED lamp that makes a bright and white light.

Let’s start.

To wash the parts you need essentially:

a) an ultrasonic bath washing machine;

b) a cleaning solution (to be mixed with clear water – I use the demineralised one for the iron);

c) a small watchmaker basket (a metallic basket made with a very thin net in order to keep the smallest parts like screws and springs);

d) an hairdryer to dry the parts after the cleaning bath (VERY IMPORTANT, otherwise you risk to rust some parts – especially the chronograph module that I don’t dismantle – if water remains trapped somewhere);

e) eventually a dust blower, to blow the remaining water out from the holes of the bridges during the drying process (see further).

To wash the parts the pro watchmakers have an expensive and powerful cleaning machine that can wash all the parts together making a pre-washing and a deep-washing with various solutions, obviously this is not my case… I use a quite cheap ultrasonic bath “Becosonic S1” (can be found here http://www.watch-tool.de/html/cleaning_testing.php?id=0280), it can contain 0.6 litre of cleaning solution so can wash only few parts at a time and must repeat the process many times changing, into the basket, the parts to be cleaned.

As cleaning solution I use “Sambol Platina 1:20” (can be found here http://www.watch-tool.de/html/cleaning_testing.php?id=0281bj), essentially I think (from the terrible smell) it is an ammonia-based liquid to be mixed with water in parts 1:20 (if you prepare 1 litre of solution you will need 50 cc of Sambol).

Take care to prepare the solution in an well-aired place (WARNING: this product is flammable, irritating to respiratory system and skin and can seriously damage the eyes, so absolutely don’t breath its vapors) BUT please don't contaminate the solution (so don’t prepare it in the garden under a tree, I usually prepare it in the kitchen under the hood of the stove to take away the fumes).

Assuming you already have the solution ready and loaded into the ultrasonic bath:

1) start to put some parts into the basket. Some watchmakers put all the parts together in the basket (image taken from the web):

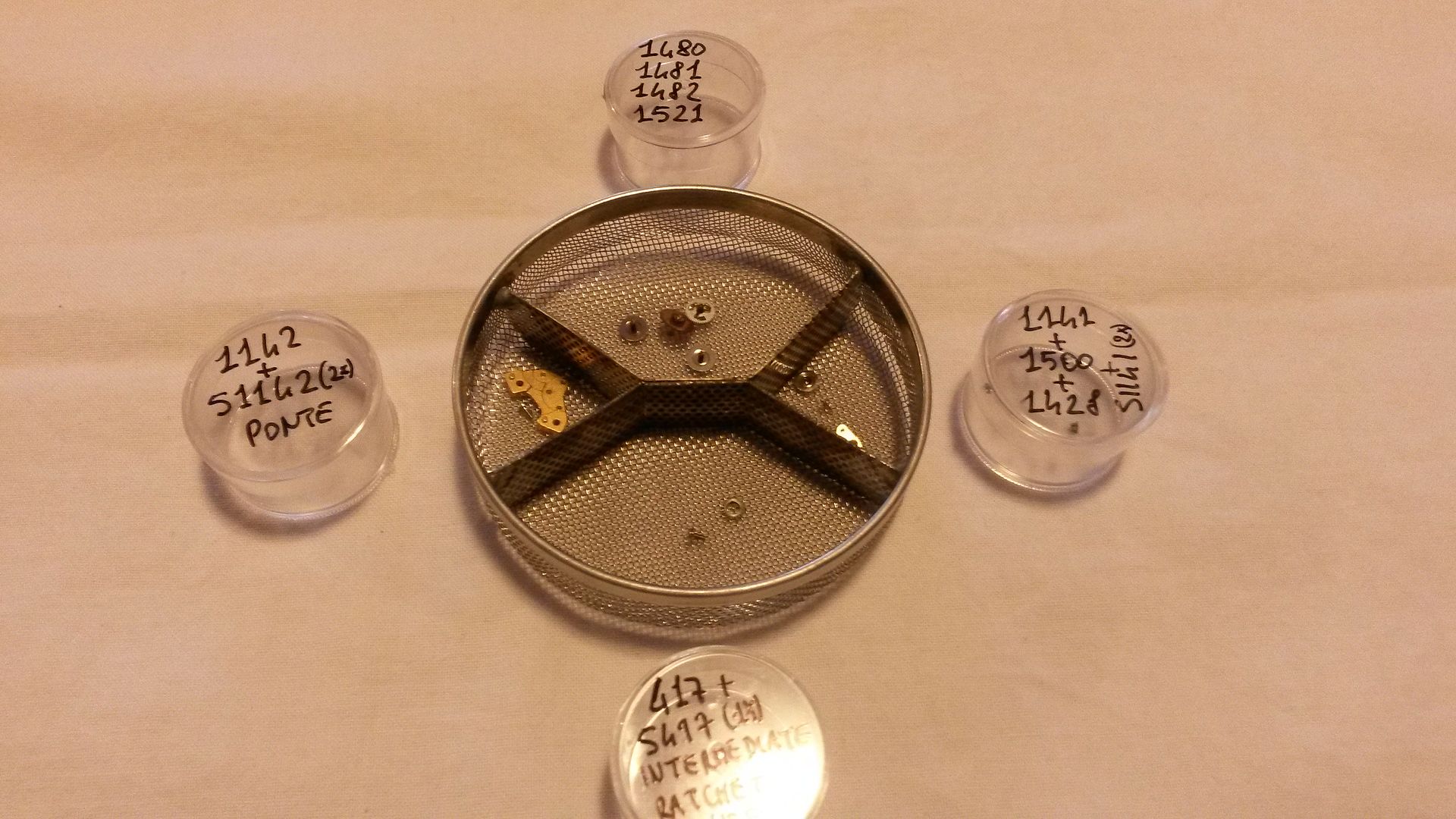

I instead keep them separated as I would never distinguish the screws anymore once mixed together, my basket is divided in four sections so I put, in each section, the parts as I stored when I dismounted them (usually a wheel with its screw/s or groups of wheels that cannot be confused each other):

2) Put the basket into the bath (use the rubber gloves, the cleaning solution irritates the skin) and start the machine: mine is very basic and doesn’t have the possibility to set the time, every cycle lasts 3 minutes, so usually I use a double shot (6 minutes) for parts not so dirty (all the wheels and the screws for instance) while repeat the cycle 3x or 4x (so 9 or 12 minutes total) if parts are really dirty (e.g. the mainspring barrel usually has dried grease to be removed on the inner barrel walls) or have a complex geometry (I wash the chronograph module 6 min on each side, changing it into the basket as a steak on the grill).

3) After the ultrasonic bath put the basket for 3 minutes or so in a container filled only with clean water (the demineralised one) in order to remove traces of the cleaning solution from the parts;

4) Put the basket on the absorbing paper to remove as much water as possible from the metallic net;

5) in the end start drying gently the parts into the basket with the hairdryer (warm air, NOT hot) taking care the air flow is coming over the basket and not under it (some parts are so thin and light that can fly off the basket if invested by an air flow with bottom-up direction);

6) Unload the basket (use the rubber gloves) putting back the cleaned parts in their small plastic boxes, ready for the next step (reassembling + oiling).

IMPORTANT: take care to perfectly dry all the parts before unloading the basket, water tends to be trapped into the oil sinks of the jewel holes and rust the metallic ones if not dried.

For the chronograph module I also use the dust blower to expel the water from it, and hold the module in my hands (with gloves) – not in the basket – while drying to dry all the sides.

Repeat the above points (load the basket with parts, do the ultrasonic bath, clean with clear water, basket on the absorbing paper, drying with hairdryer, unload the basket) with another set of parts until you will end them (so if you have 20 plastic boxes where parts have been stored you will need 5 separate loop to clean them all).

I usually take a couple of hours to wash and dry all the parts of a Chronomatic movement.

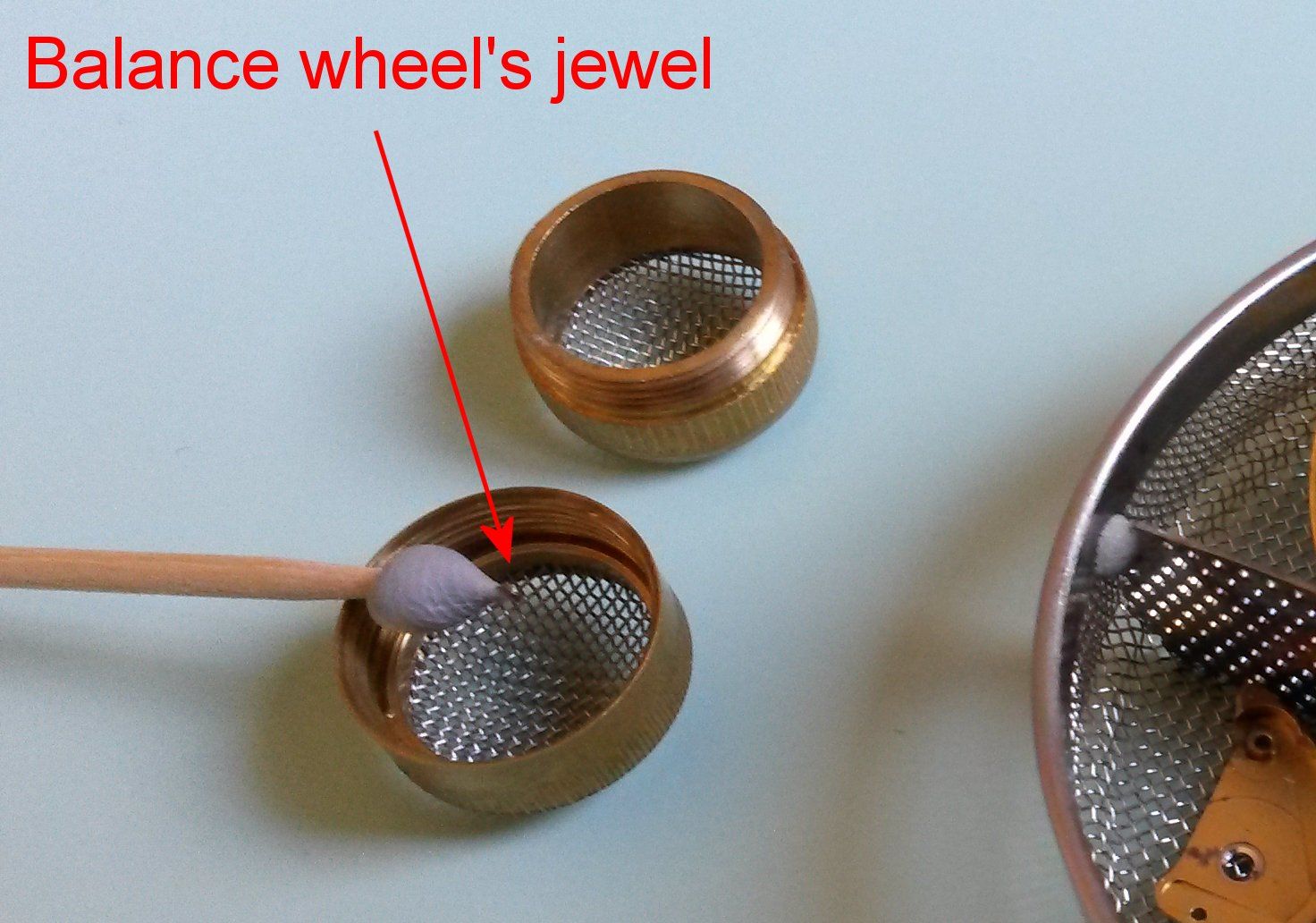

For the jewels of the balance wheel, the stones are so little that I use another mini-basket to keep them while cleaning:

That’s all.

Would be great if someone else would add his experience in order to have a knoledgeable database on this argument.

All my best.

Gianluca

| Chronocentric and zOwie site design and contents (c) Copyright 1998-2005, Derek Ziglar; Copyright 2005-2008, Jeffrey M. Stein. All rights reserved. Use of this web site constitutes acceptance of the terms of use. | CONTACT | TERMS OF USE | TRANSLATE |