| Informational Websites | ChronoMaddox -- the legacy of Chuck Maddox | OnTheDash -- vintage Heuer website | Zowie -- Omega information |

| Discussion Forums | ChronoMaddox Forum | Heuer Forum | Omega Forum |

| Counterfeit Watchers | ChronoTools Forum | ChronoTrader Forum |

|

|

The largest independent, non-commercial, consumer-oriented resource on the Internet for owners, collectors and enthusiasts of fine wristwatches. Online since 1998. | |||||||

|

||||||||

|

||||||||

|

Vintage Heuer Discussion Forum

The place for discussing 1930-1985 Heuer wristwatches, chronographs and dash-mounted timepieces. Online since May 2003. | ||||||

| |||||||

| |||||||

We are three days into 2016, and I am thrilled to see this posting!!

Huge thanks for this labor of love!!

Jeff

+++++++++++++++++++++++++++

: Hi all,

: Taking advantage of the Xmas holidays I thought to prepare this

: post, that is the ideal prosecution of the two previous posts

: about “How to disassemble a Chronomatic movement”:

: http://chronocentric.com/forums/heuer/index.cgi?md=read;id=79646

: and “How to clean a Chronomatic movement (part 2)” (quite

: trivial and generic and valid for all types of movements):

: http://chronocentric.com/forums/heuer/index.cgi?md=read;id=79689

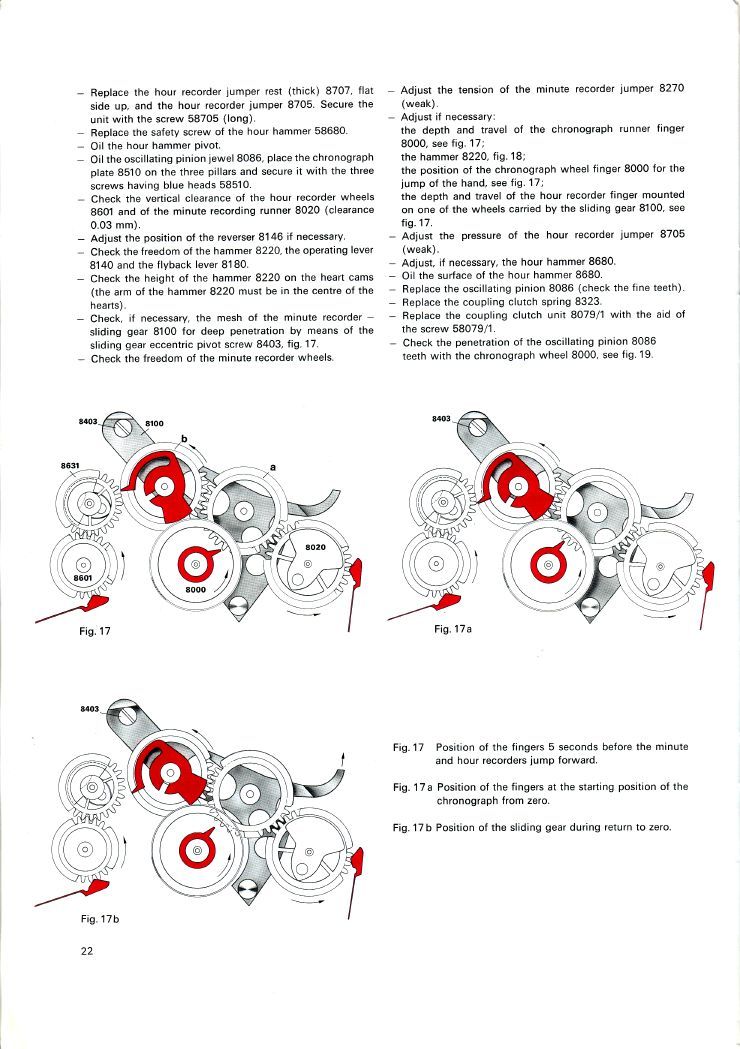

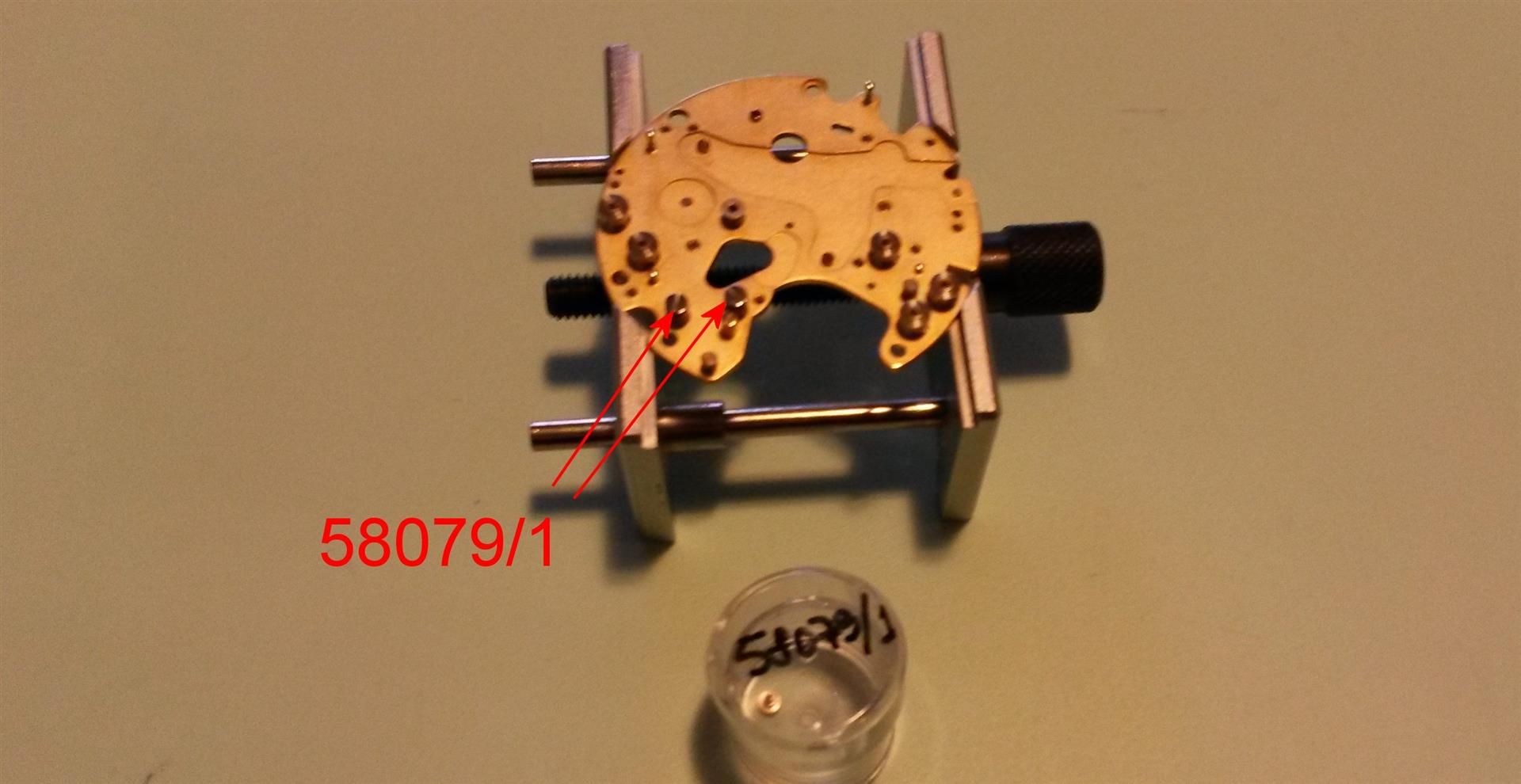

: In the first post we saw that usually is not necessary to

: disassemble the chrono module to service it (this is also stated

: into the service manual, see pag.14), you can put it directly

: into the ultrasonic bath and, after having carefully dried it

: (to avoid the trapped water may rusts some parts) you will only

: need to dismount the two bridges and eventually a couple of

: screws to reach some points to be oiled (as we will see in this

: post).

: However this time we will see how to reassemble, step by step, the

: chrono module just for sake of information (can happen you have

: to partially dismount it, e.g. to replace some broken / rusted

: parts) and to ideally conclude the first post, so will see in

: details all the steps described in the following four pages of

: the service manual (you can find it on OTD too or on the Chuck

: Maddox website):

:

:

:

:

:

:

:

:

: I will only make three important assumptions, that are:

: a) the chronograph module, before servicing, is working well and

: doesn’t need any regulation: in fact, into this module, there

: are some eccentric screws that is essential NOT to touch unless

: you need it (e.g to regulate the penetration of the oscillating

: pinion 8086 into the central chrono wheel 8000), otherwise you

: risk to deregulate one or more of the functions of the

: chronograph.

: b) we will not explain the techniques involved in the art of oiling

: a watch (this would deserve an apposite post) so I will make the

: assumption that the reader knows how to oil / grease a watch and

: the differences involved among the various oils and greases

: needed.

: c) All the parts of the chronograph module have already been

: dismounted and cleaned, so we are ready to reassemble it.

: Banally to dismount it you can follow the following steps

: bottom-up, obviously avoiding the oiling notes :-).

: To service the chronograph module (its code is 8510 if fully

: mounted or 8281 for the base plate) only two lubricants are

: needed:

: a) Synt-a-Lube: this is a thin oil, suitable for the pivot holes of

: “fast moving” wheels (e.g. the balance wheel’s jewels 324

: and 325 of the main module, the oscillating pinion 8086) or

: wheels with very low pressure (all the chronograph module’s

: ones). I use the Moebius 9010.

:

:

: b) Bergeon KT22: this is a grease (not an oil) and is used in the

: manual winding mechanism (here the wheels haven’t shafts but

: are similar to washers, so have a large surface to be lubricated

: but are relatively slow with an high load to sustain to wind the

: mainspring), in the setting mechanism, and in many points of the

: chronograph module where parts rubs one each other. I use the

: Bergeon KT22 but Moebius 8200 should be the same.

:

:

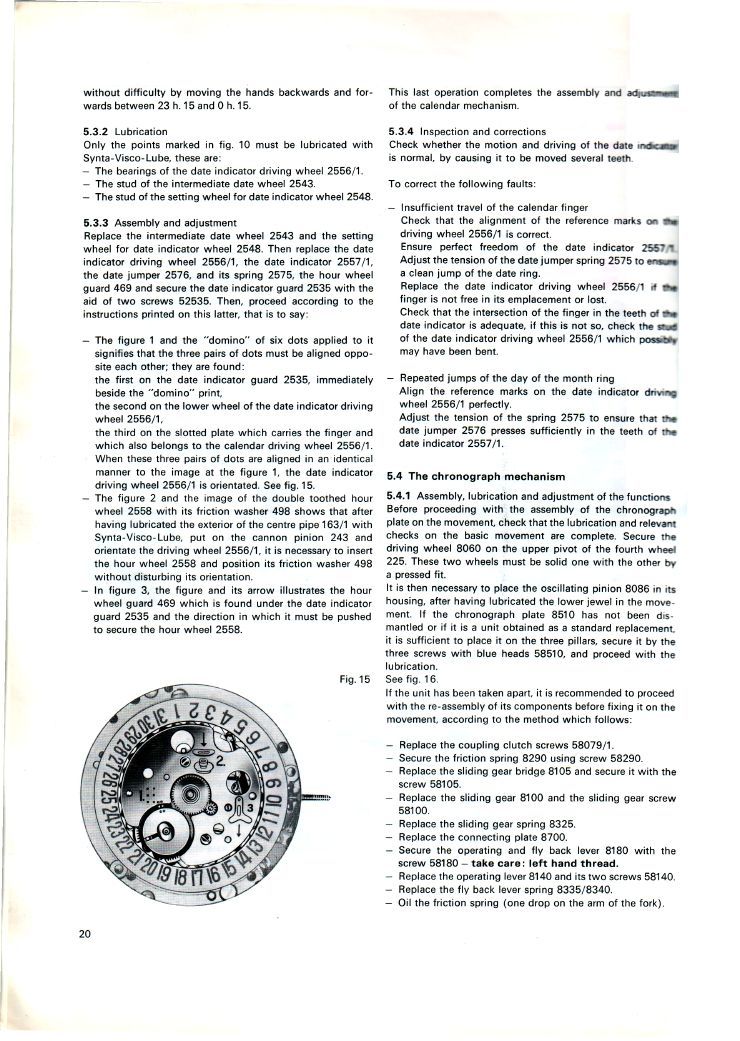

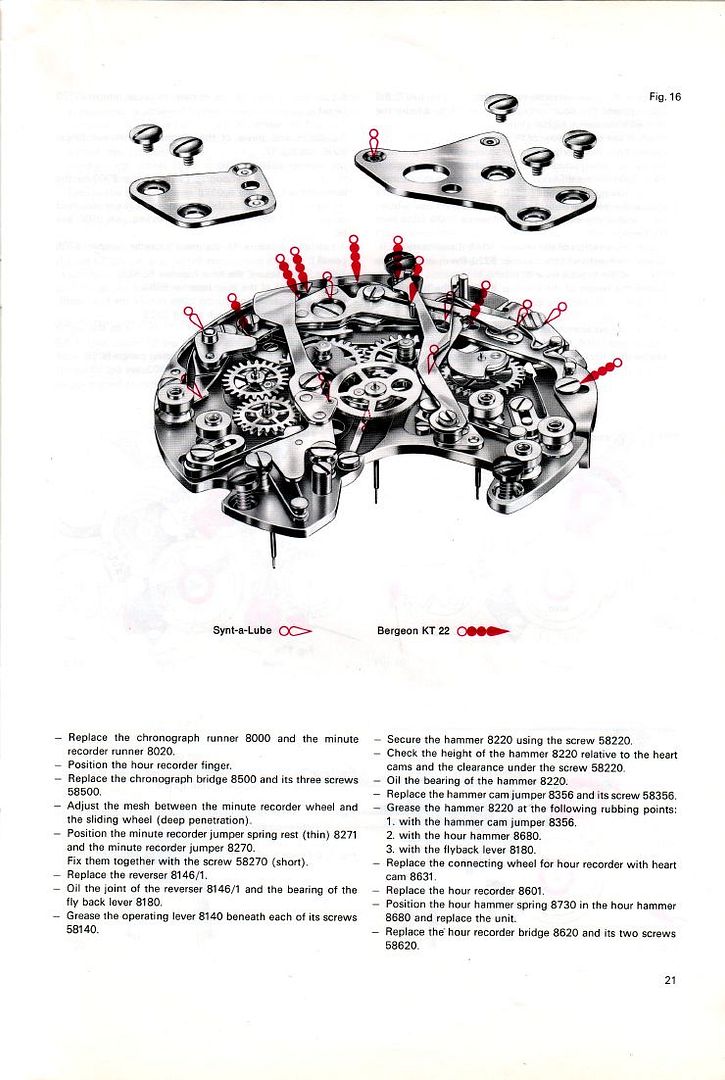

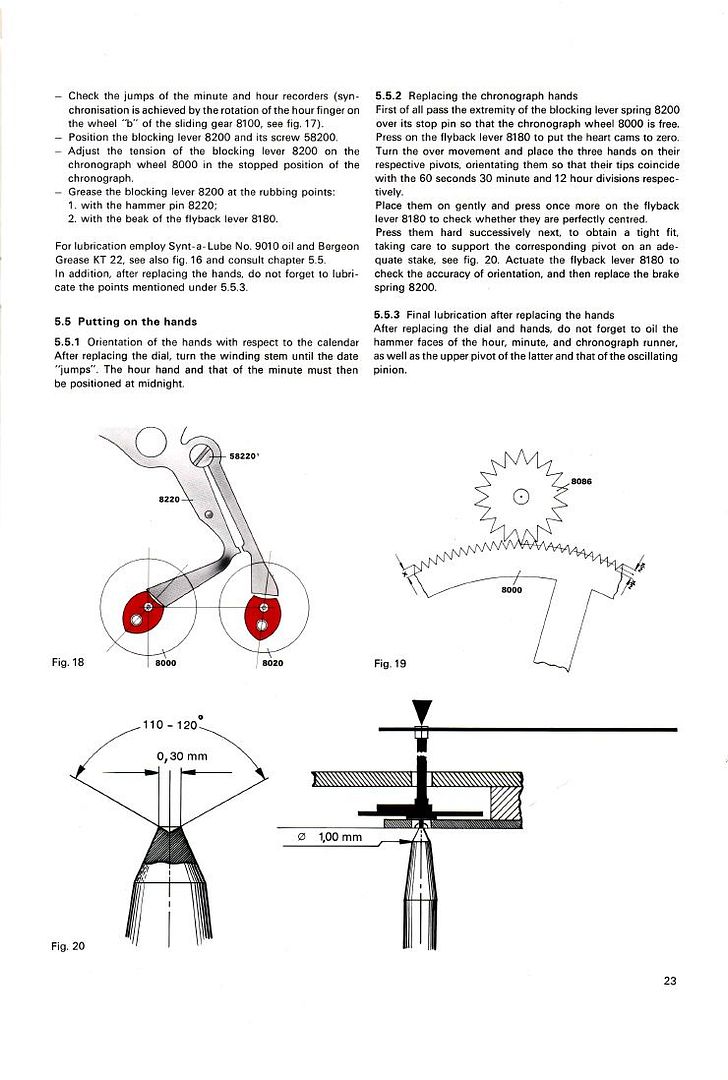

: The following image is taken from the service manual and illustrate

: the “lubrication plan” of the chronograph module (that is

: “which oil or grease to put where”).

: Obviously the oil or grease must be applied during the reassembling

: process of the parts in the points specified into the image.

:

:

: Let’s start.

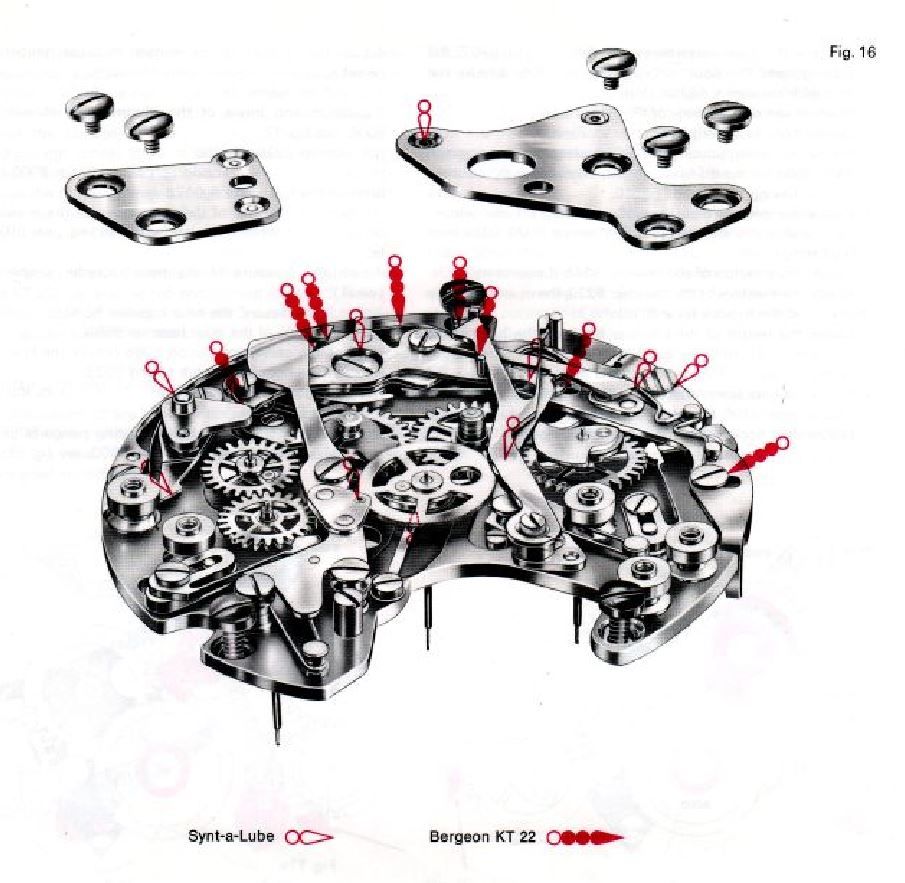

: This is the naked 8281 chronograph plate, already fitted with

: bushes and regulating screws (into the Cal12/14/15 the latter

: are usually gold coloured while into the Cal11/11i are nickel

: coloured but there are some Cal12 with nickel coloured

: eccentrics too):

:

:

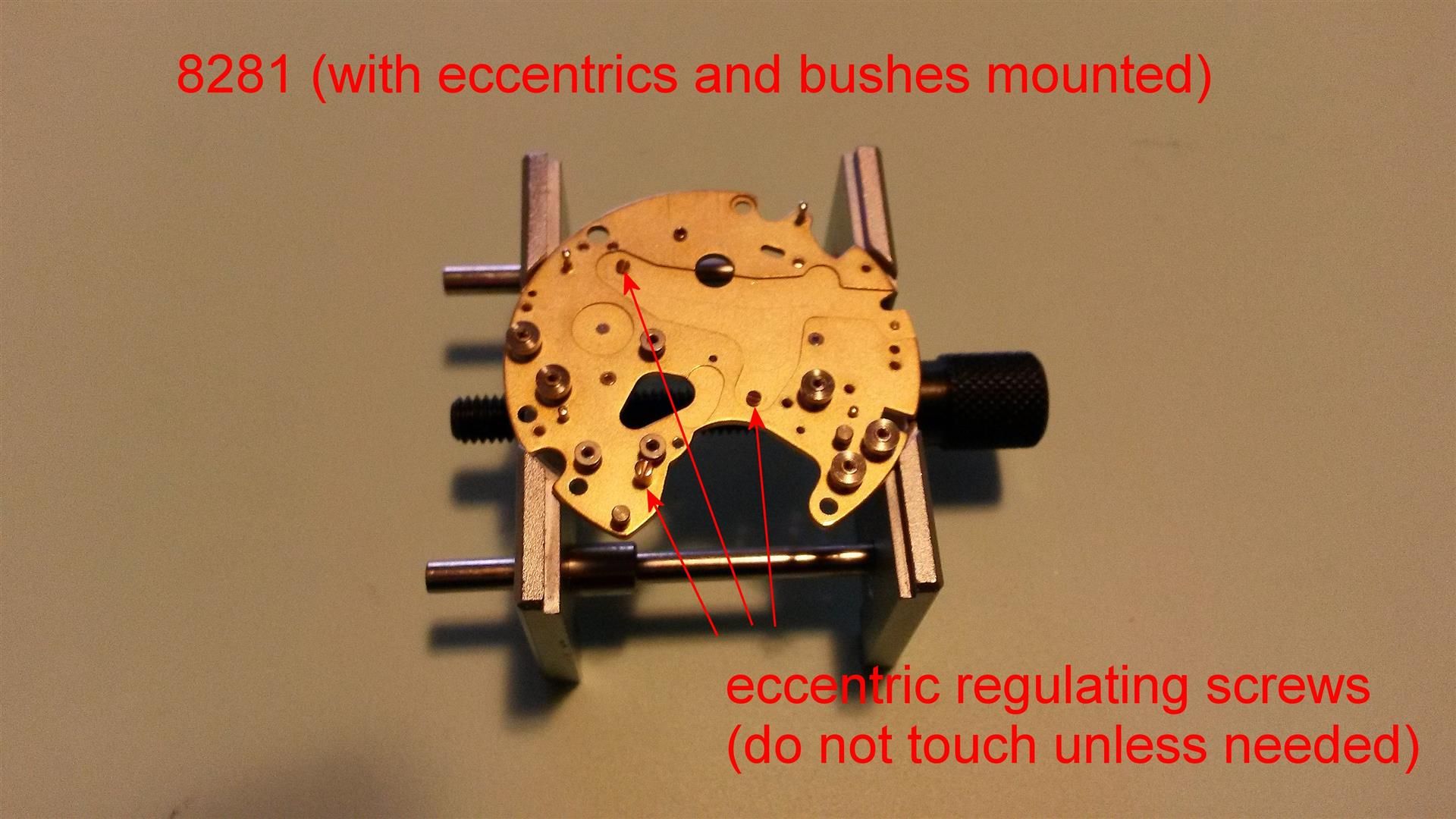

: 1) Replace the two coupling clutch screws 58079/1:

:

:

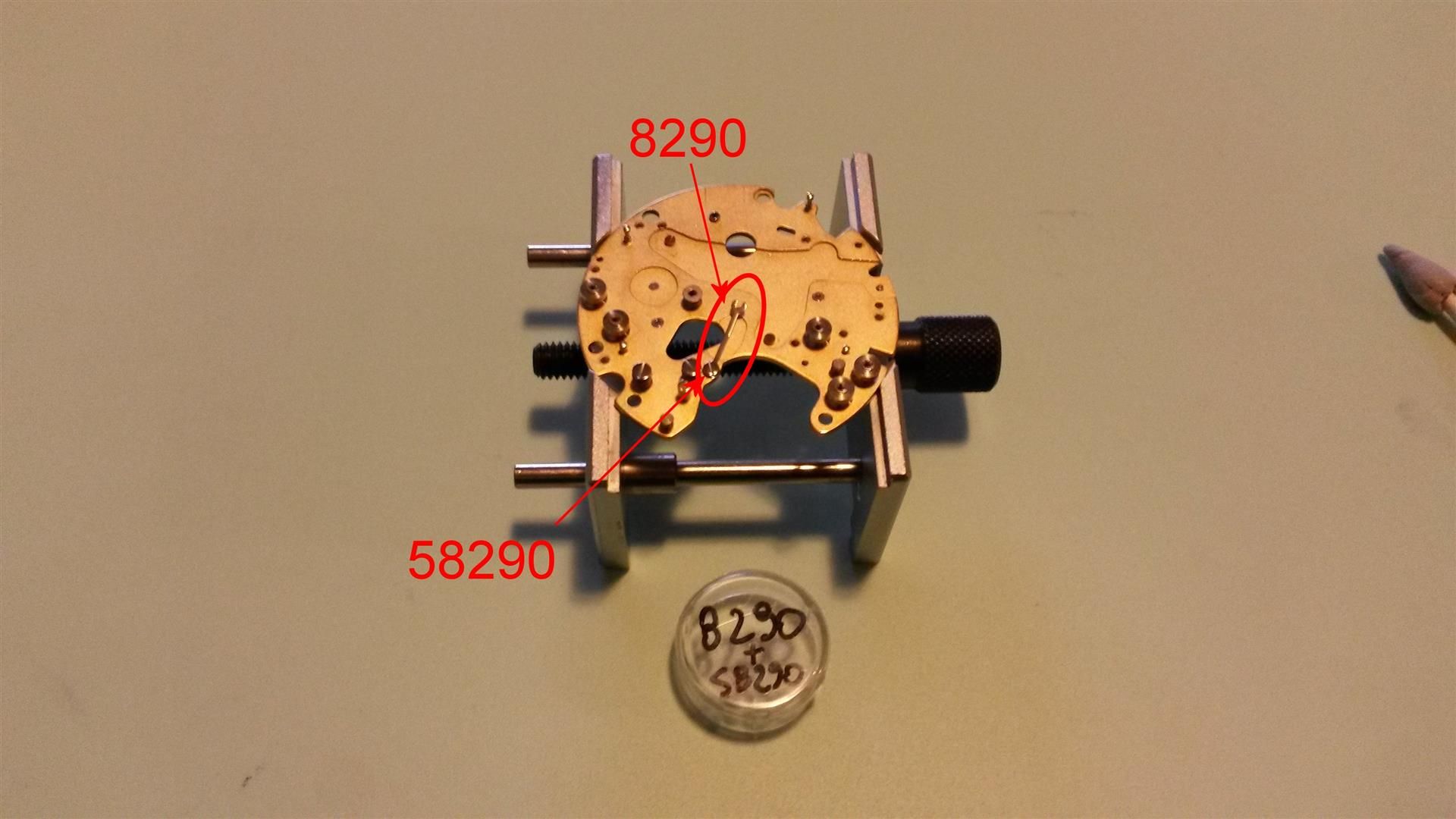

: 2) Secure the friction spring 8290 using its screw 58290:

:

:

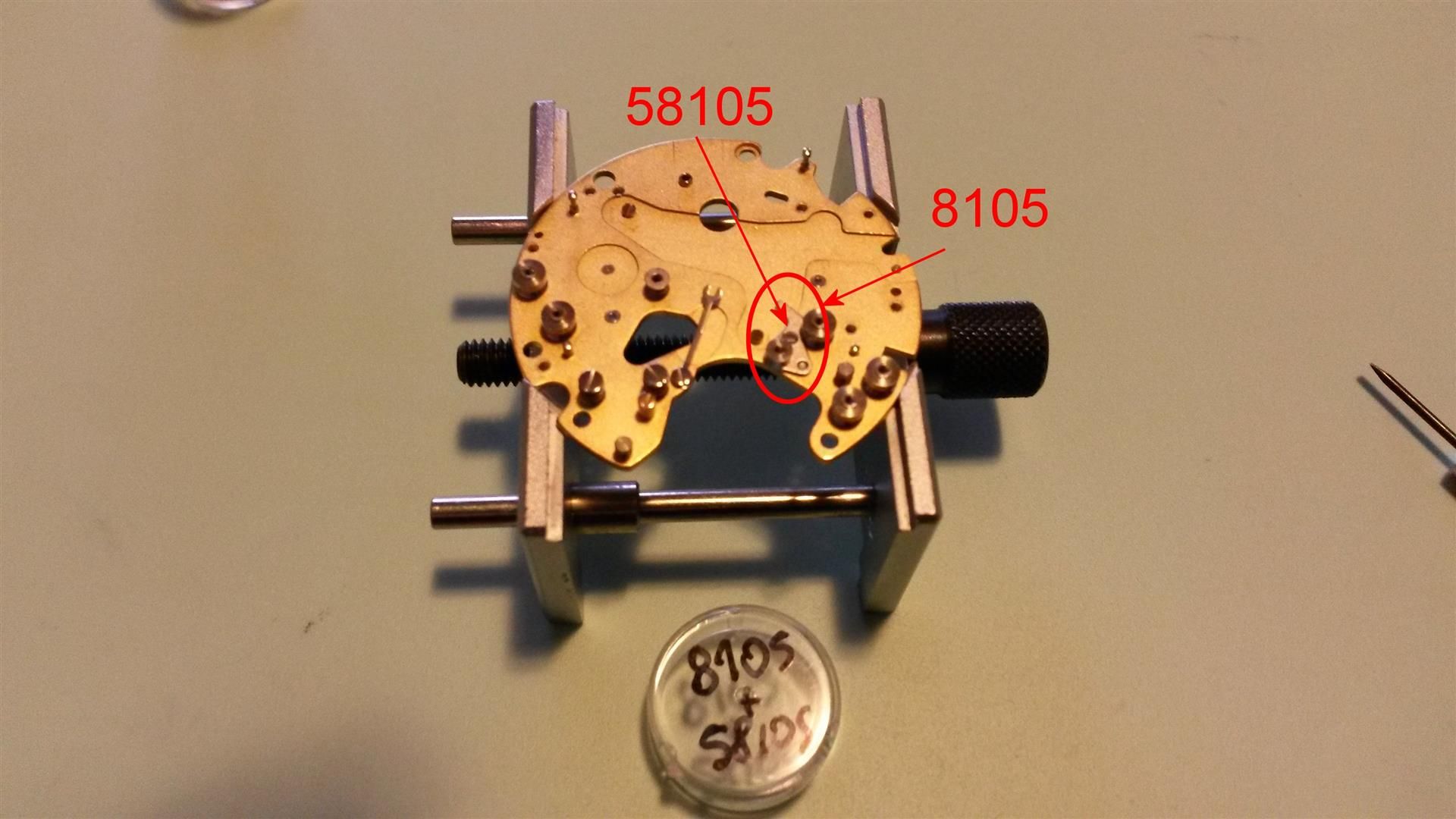

: 3) Replace the sliding gear bridge 8105 and secure it with the

: screw 58105:

:

:

: 4) Replace the sliding gear 8100 and secure it with its sliding

: gear screw 58100:

:

:

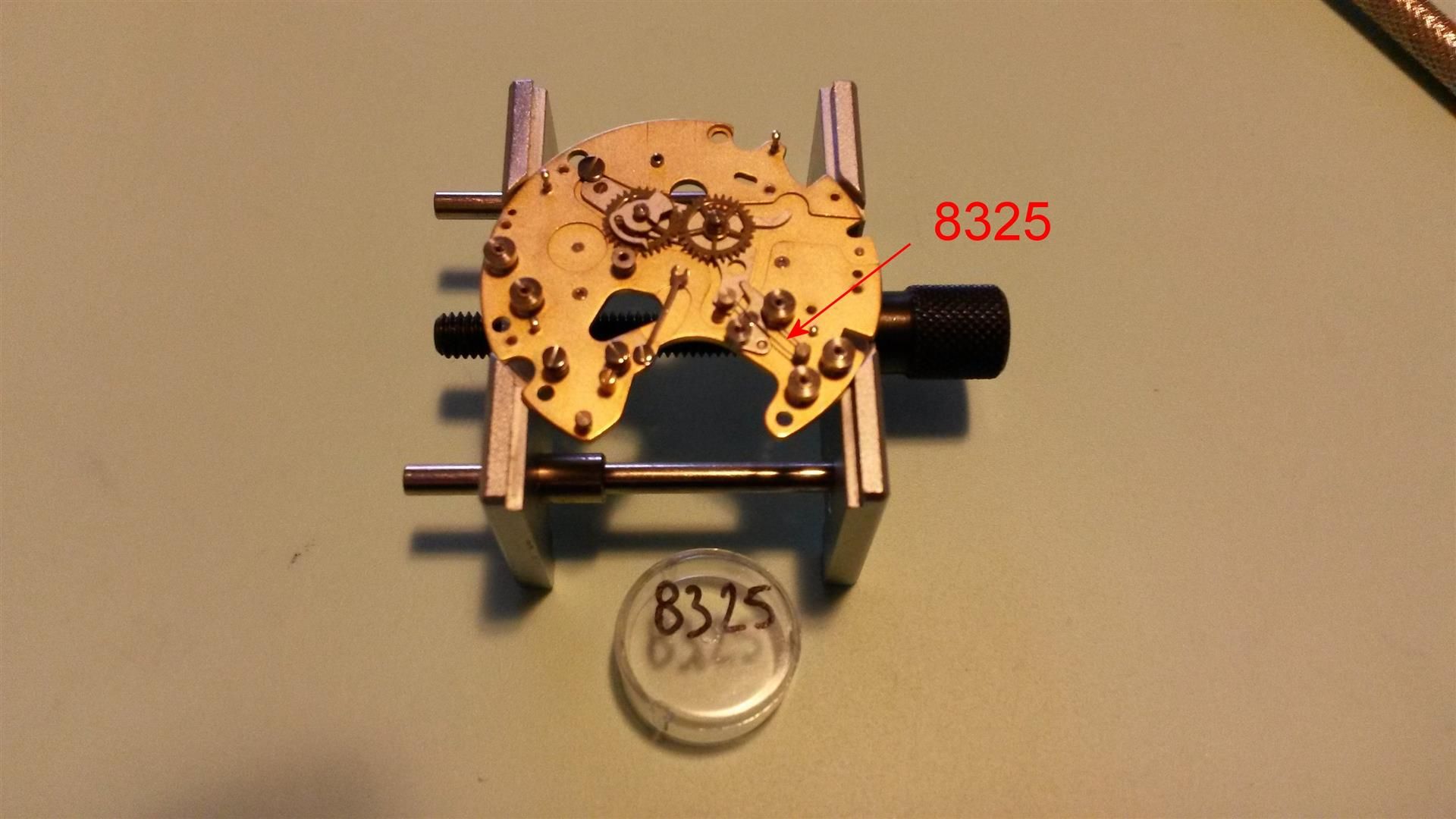

: 5) Replace the sliding gear spring 8325:

:

:

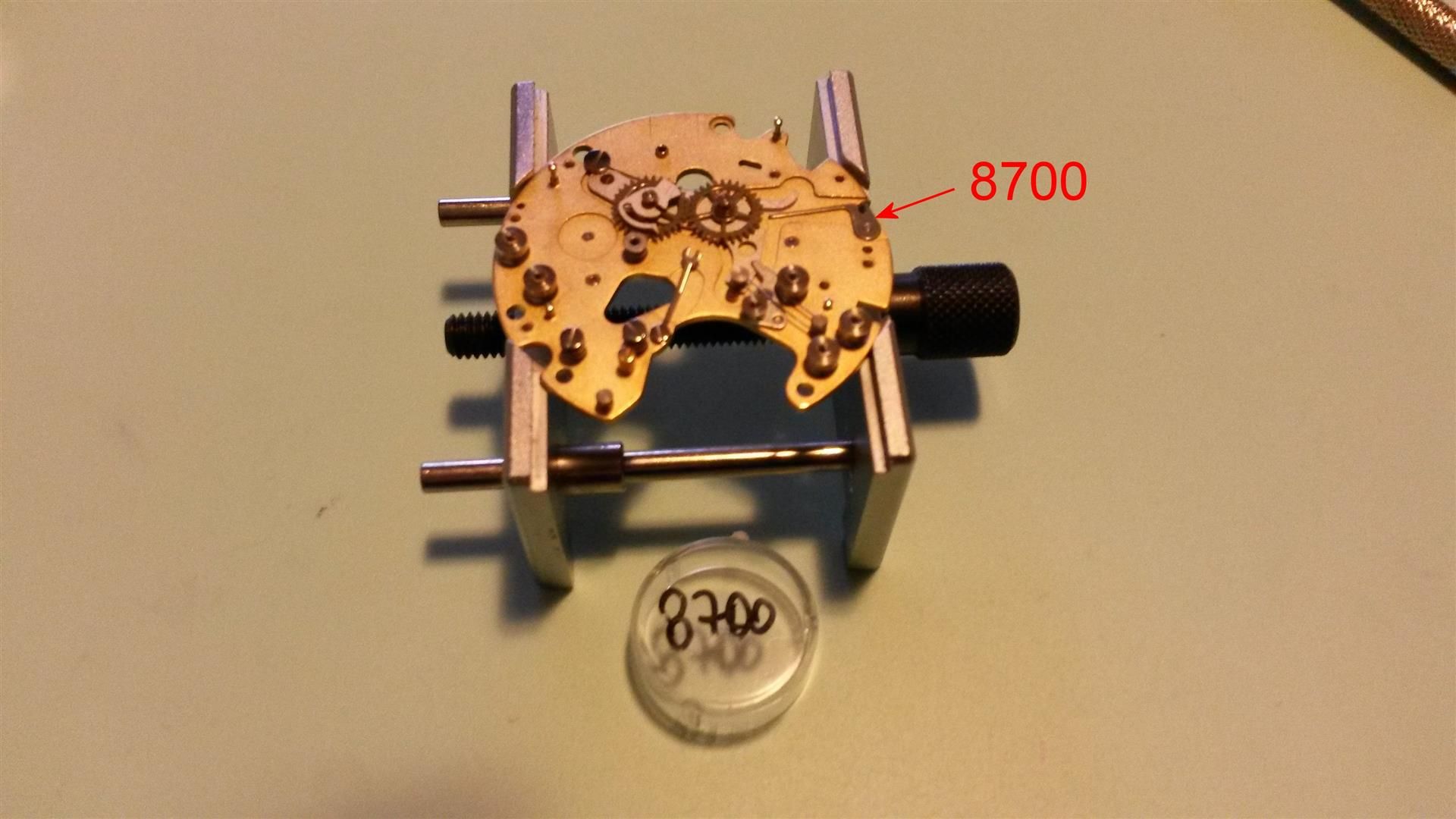

: 6) Replace the connecting plate 8700:

:

:

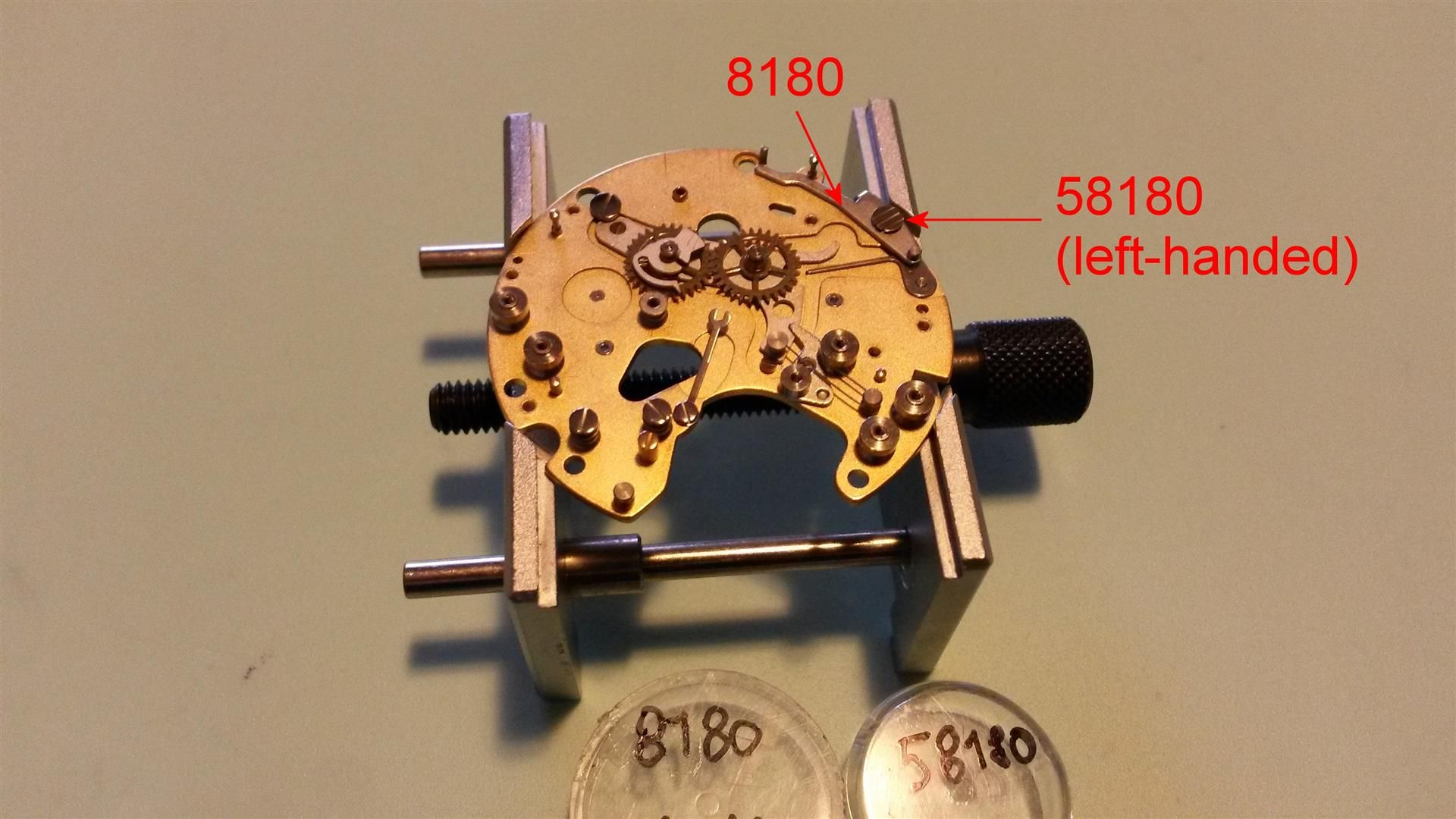

: 7) Secure the operating and fly-back lever 8180 with the screw

: 58180 (take care: is a left-hand screw!!!):

:

:

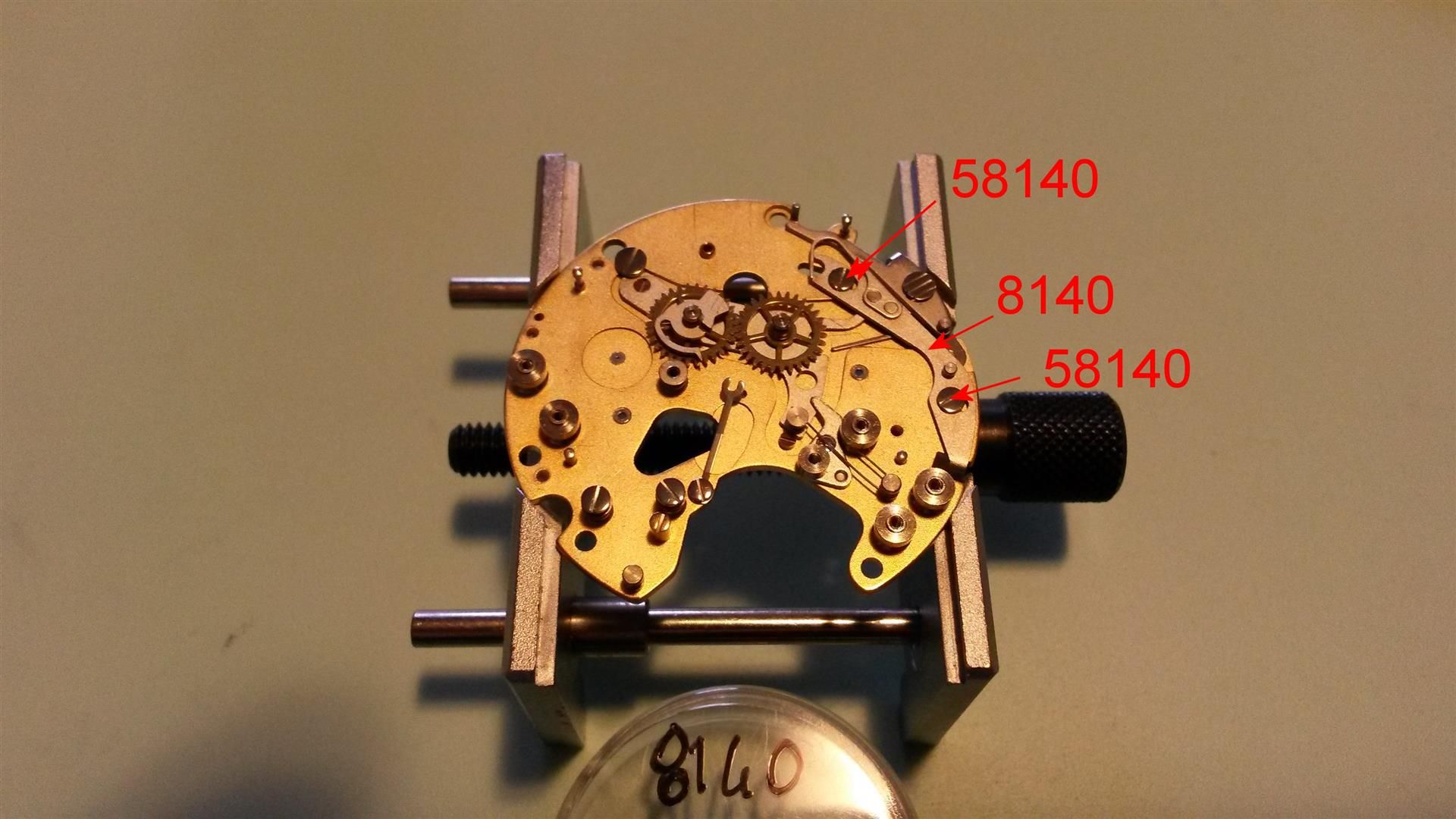

: 8) Replace the operating lever 8140 and its two screws 58140:

:

:

: 9) Replace the fly-back lever spring 8335/8340, then oil with

: Moebius 9010 the friction spring (one drop on the arm of the

: fork):

:

:

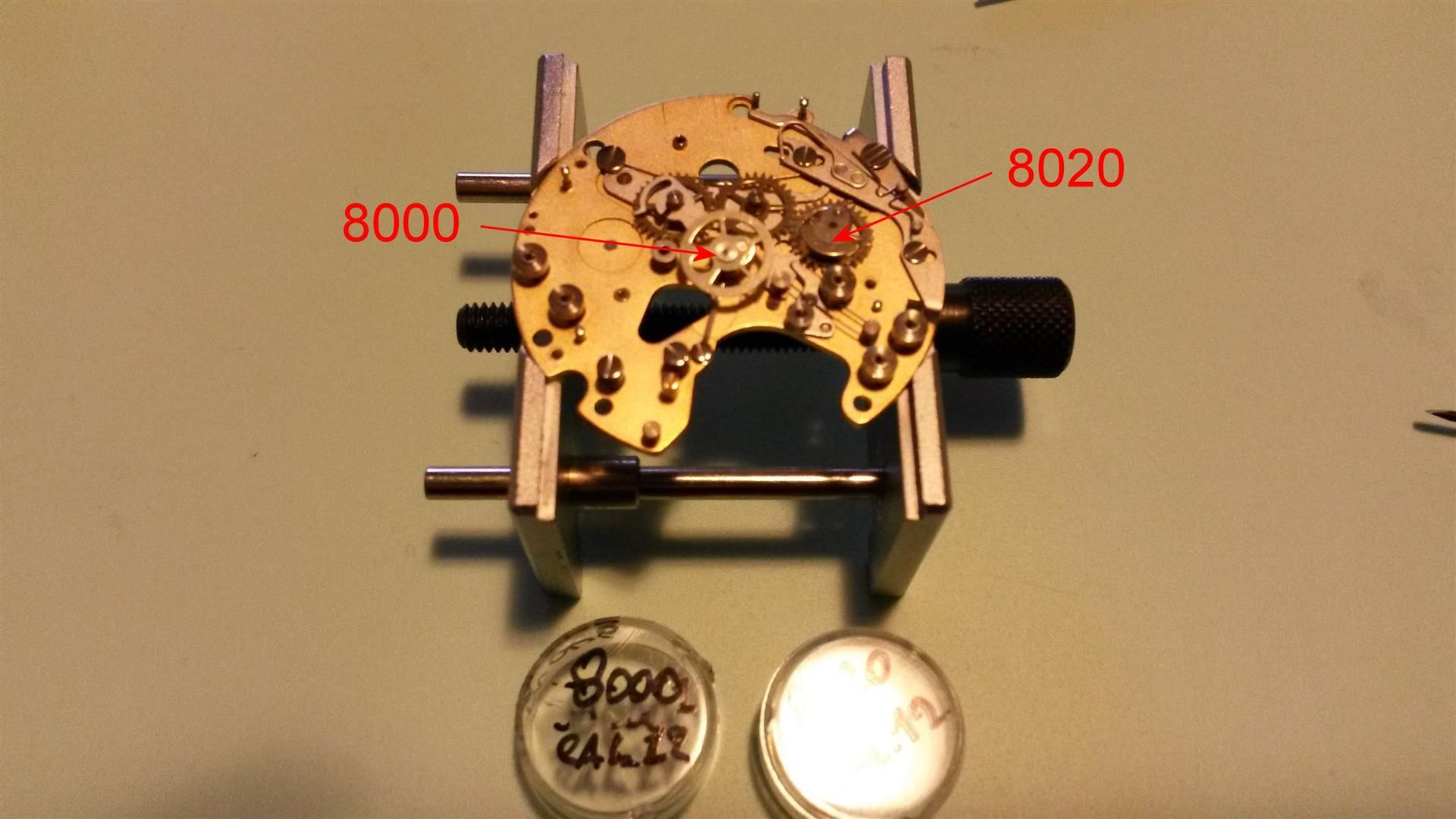

: 10) Replace the chronograph runner 8000 and the minute recording

: runner 8020:

:

:

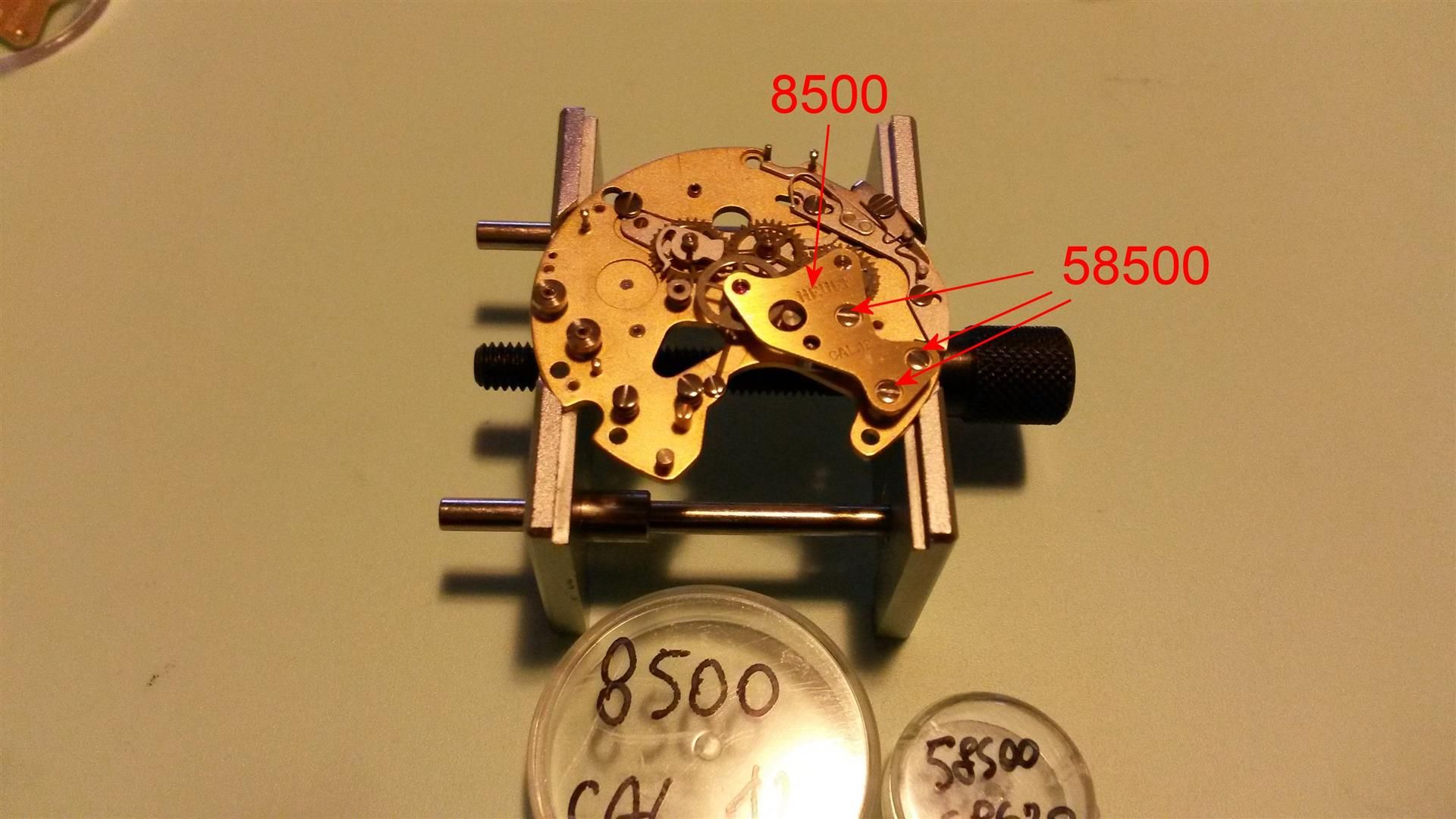

: 11) Replace the chronograph bridge 8500 with its three screws 58500

: (bear in mind that, at the end of the reassembling, we will have

: to dismount it again to add a lever, so don’t tighten the

: screws):

:

:

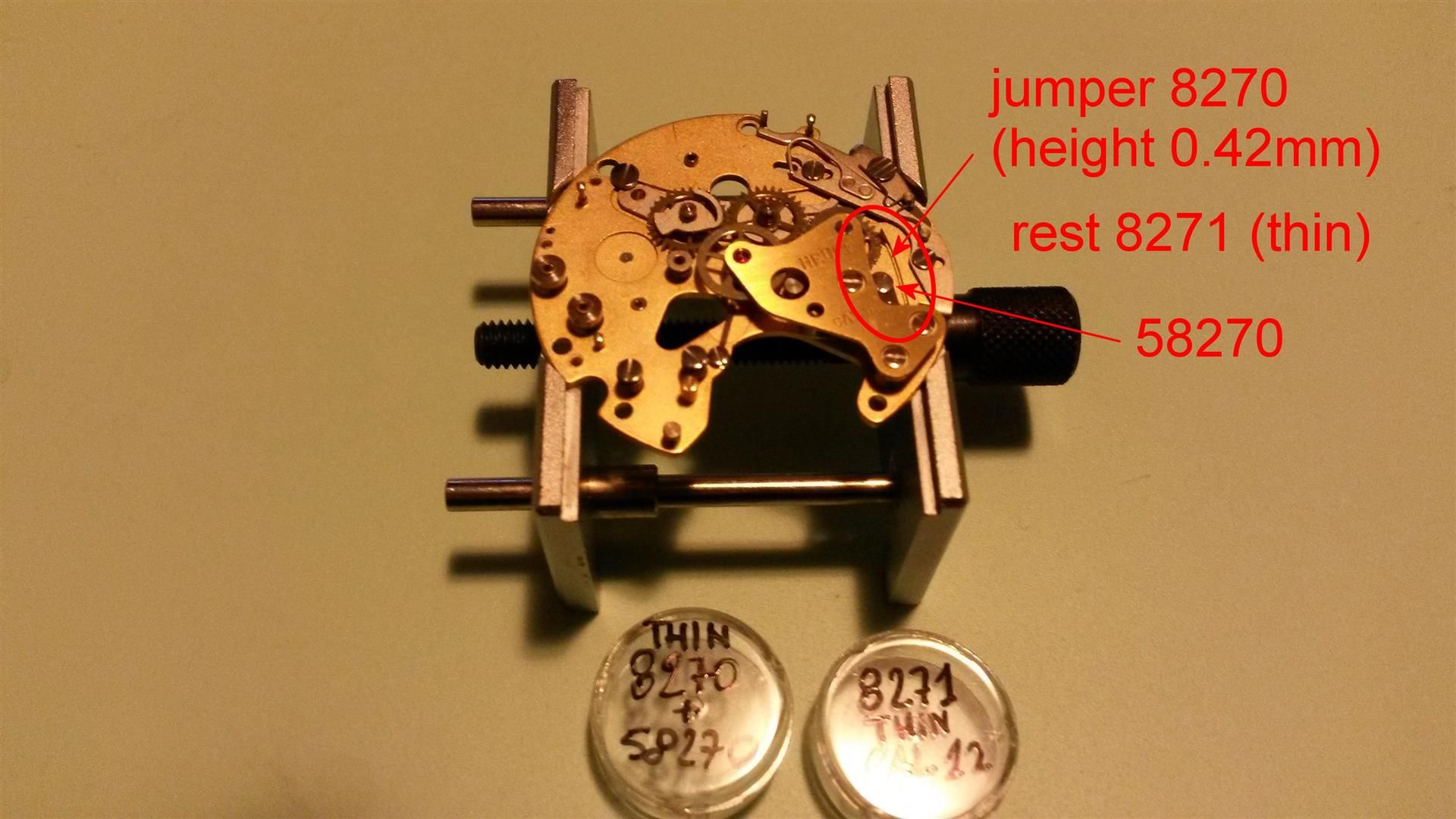

: 12) Position the minute recorder jumper spring rest 8271 (is the

: thinner one) and the minute recorder jumper 8270, then fix them

: together with the screw 58270 (sorry for the ugly image, is

: partially hidden):

:

:

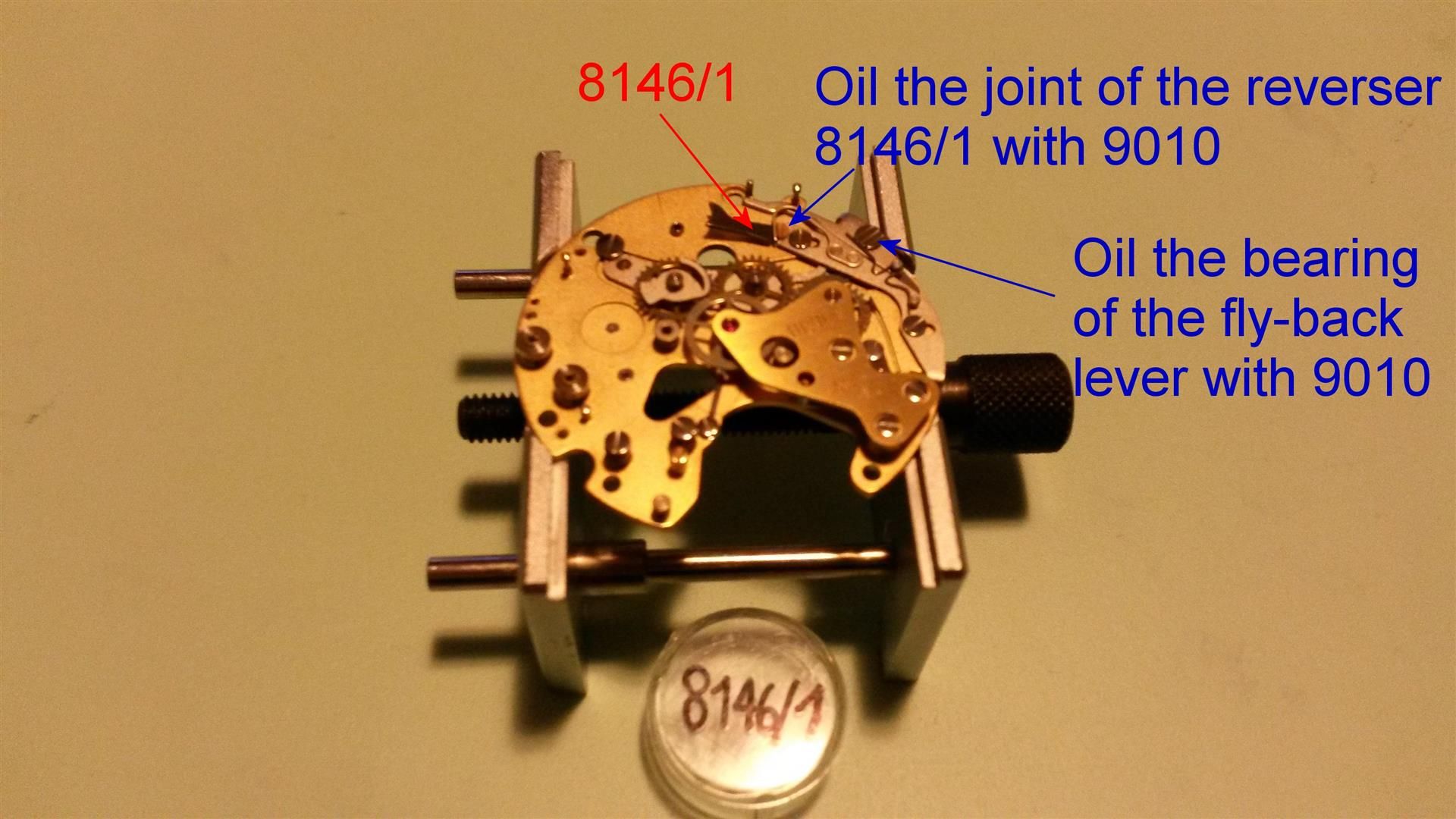

: 13) Replace the reverser 8146/1, then oil with 9010 the joint of

: the reverser (it partially rotates during the start/stop pusher

: action so needs low friction) and oil the bearing of the

: fly-back lever 8180 with 9010 and the contact point with the

: spring 8335/8340:

:

:

: 14) Replace the hammer cam jumper 8356 fixing it with its screw

: 58356, then grease with KT22 the operating lever 8140 beneath

: each of its screws 58140:

:

:

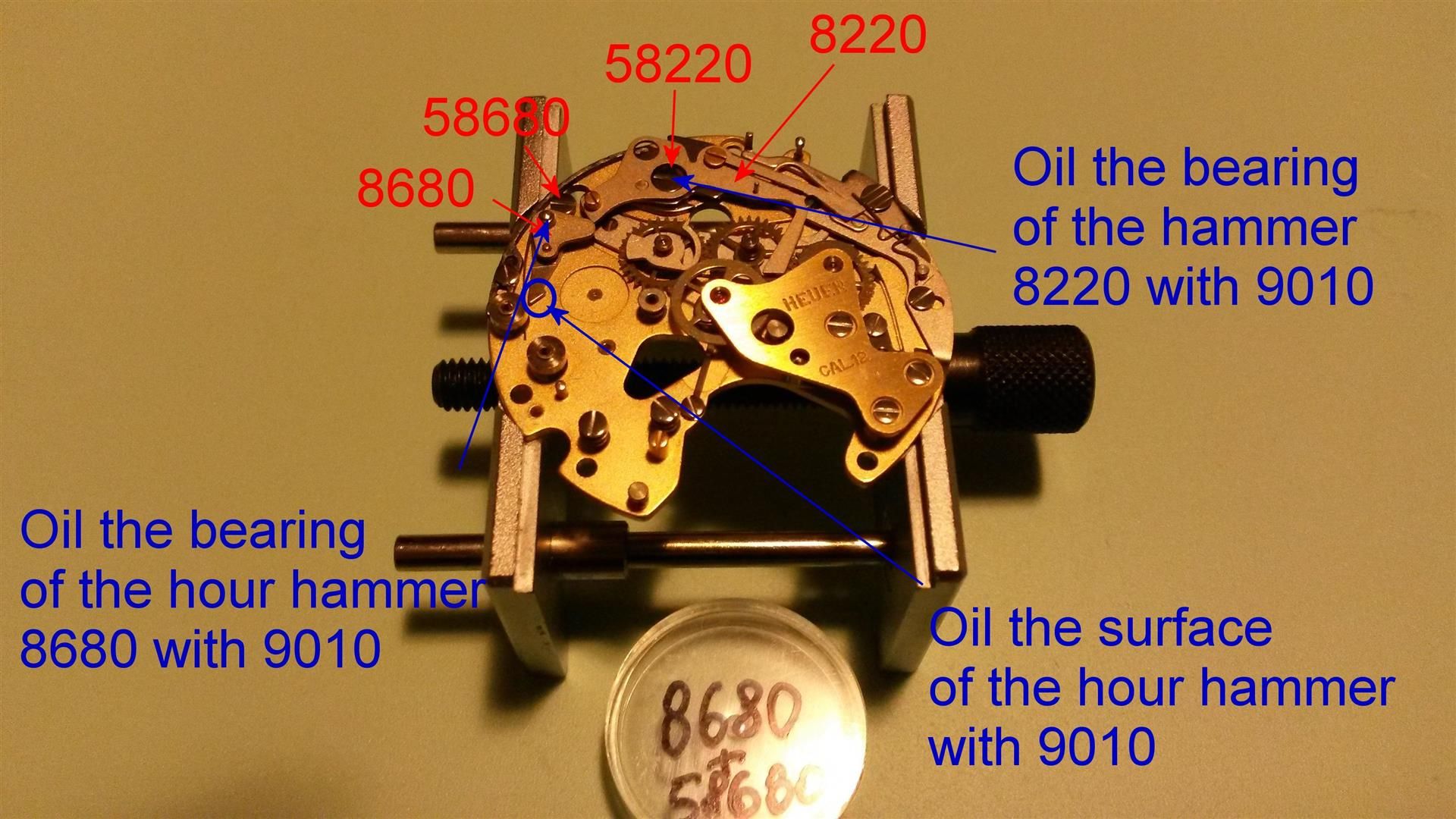

: 15) Secure the hammer 8220 using the screw 58220 (gently open the

: hammer cam jumper 8356 during the operation), then oil the

: bearing of the hammer 8220 (probably is better to put a drop of

: oil around the bearing before put the screw in order not to

: spread the oil around the hammer screw hole).

: Then replace the hour hammer 8680 (the one which resets the hour

: recorder small hand) and its safety screw 58680, leaving its

: spring free (I prefer instead to immediately tension the spring

: but is essential NOT to move the 8220 from the open position in

: order to leave the hour hammer open), then oil its pivot (like

: above, if you have the parts dismounted probably is better to

: put a drop of oil on the pivot before fitting the part).

: Oil also the surface of the hammer to avoid friction when beating

: on the heart cam of the wheel 8631 (see further):

:

:

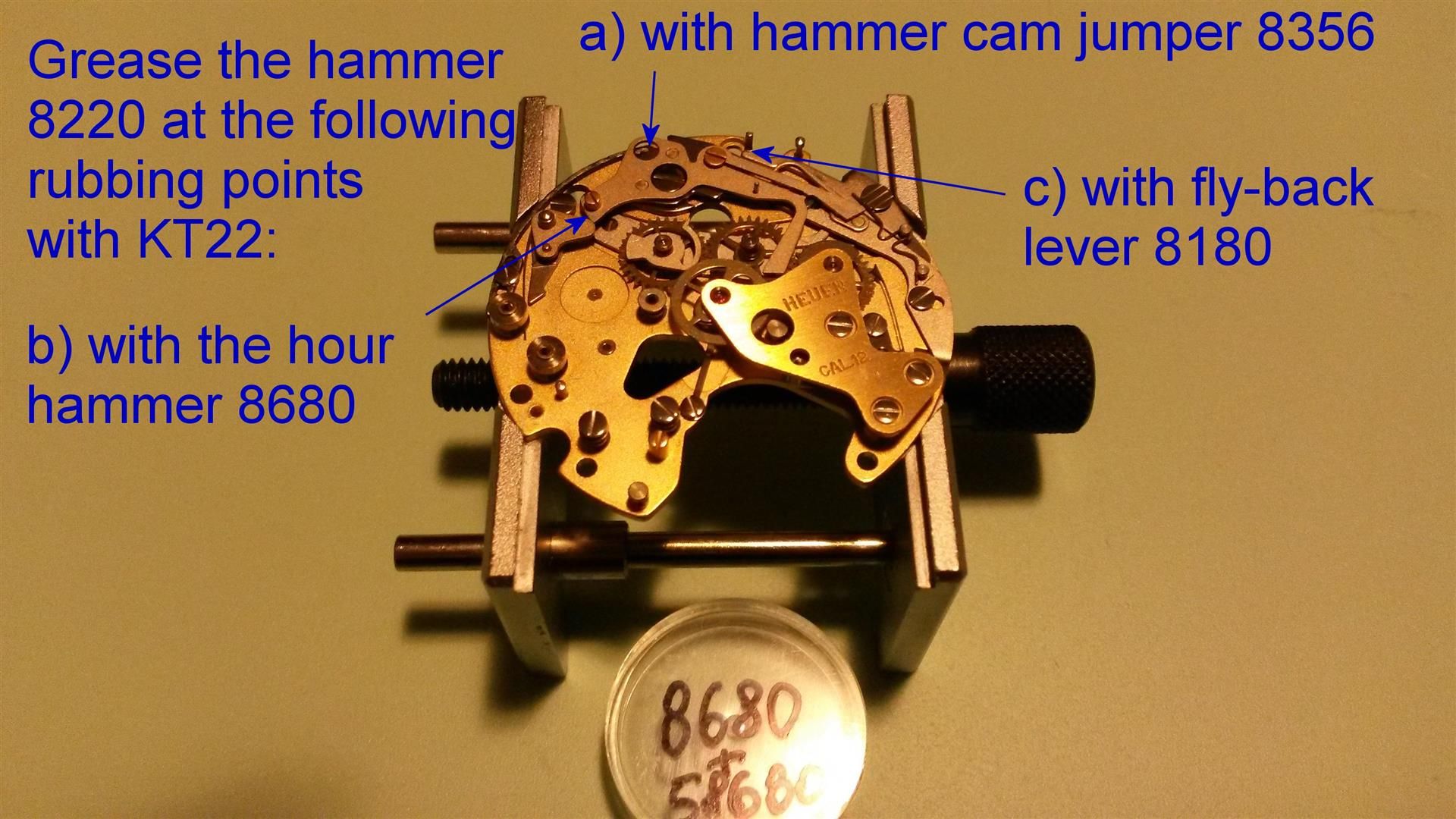

: 16) Grease with KT22 the hammer 8220 at the following rubbing

: points:

: - with the hammer cam jumper 8356 (this is essential to have a poor

: friction = smooth movement of the pushers when start / stop /

: reset, you will have to move the hammer 8220 to reach all the

: grooves to be greased and this is the reason why is better to

: position the spring of the hour hammer 8680 after this step);

: - with the hour hammer 8680;

: - with the fly-back lever 8180;

:

:

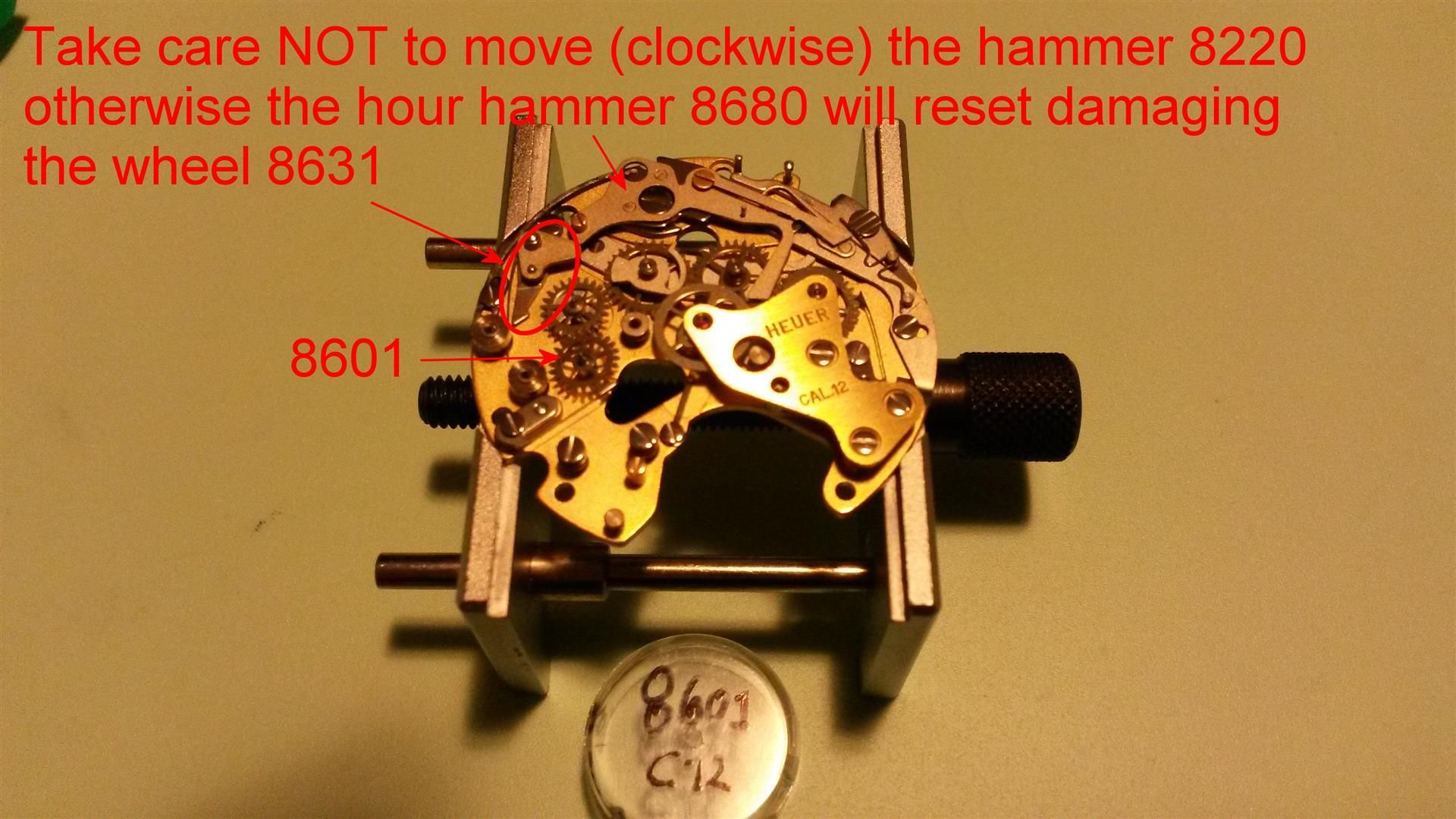

: 17) Replace the connecting wheel for hour recorder 8631 (beware:

: NOT to move the hammer 8220 for obvious reasons):

:

:

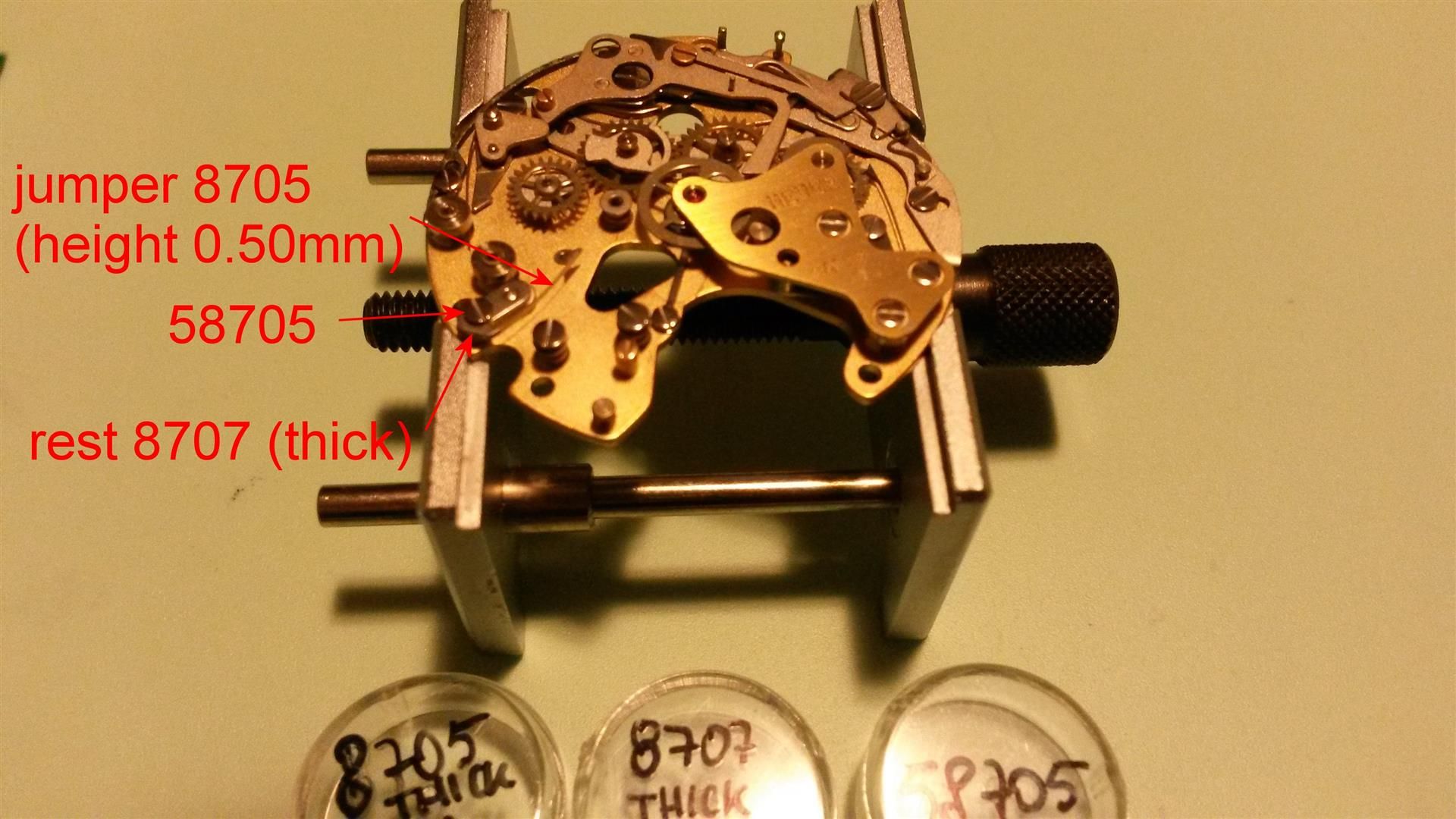

: 18) Replace the hour recorder jumper rest (is the thicker one)

: 8707, flat side up, and the hour recorder jumper 8705 (is the

: thicker one too, this is 0.50mm height while the 8270 is 0.42mm)

: and secure them with the screw 58705. I prefer to replace the

: jumper 8707 BEFORE replacing its wheel while the manual suggests

: the opposite, for me is easier as the jumper will help the hour

: recorder wheel to stay in place pressed towards the 8631 and

: thus facilitating the mounting of the bridge):

:

:

: 19) Replace the hour recorder wheel 8601. If not already done this

: is the moment to put in place the spring of the hour hammer:

:

:

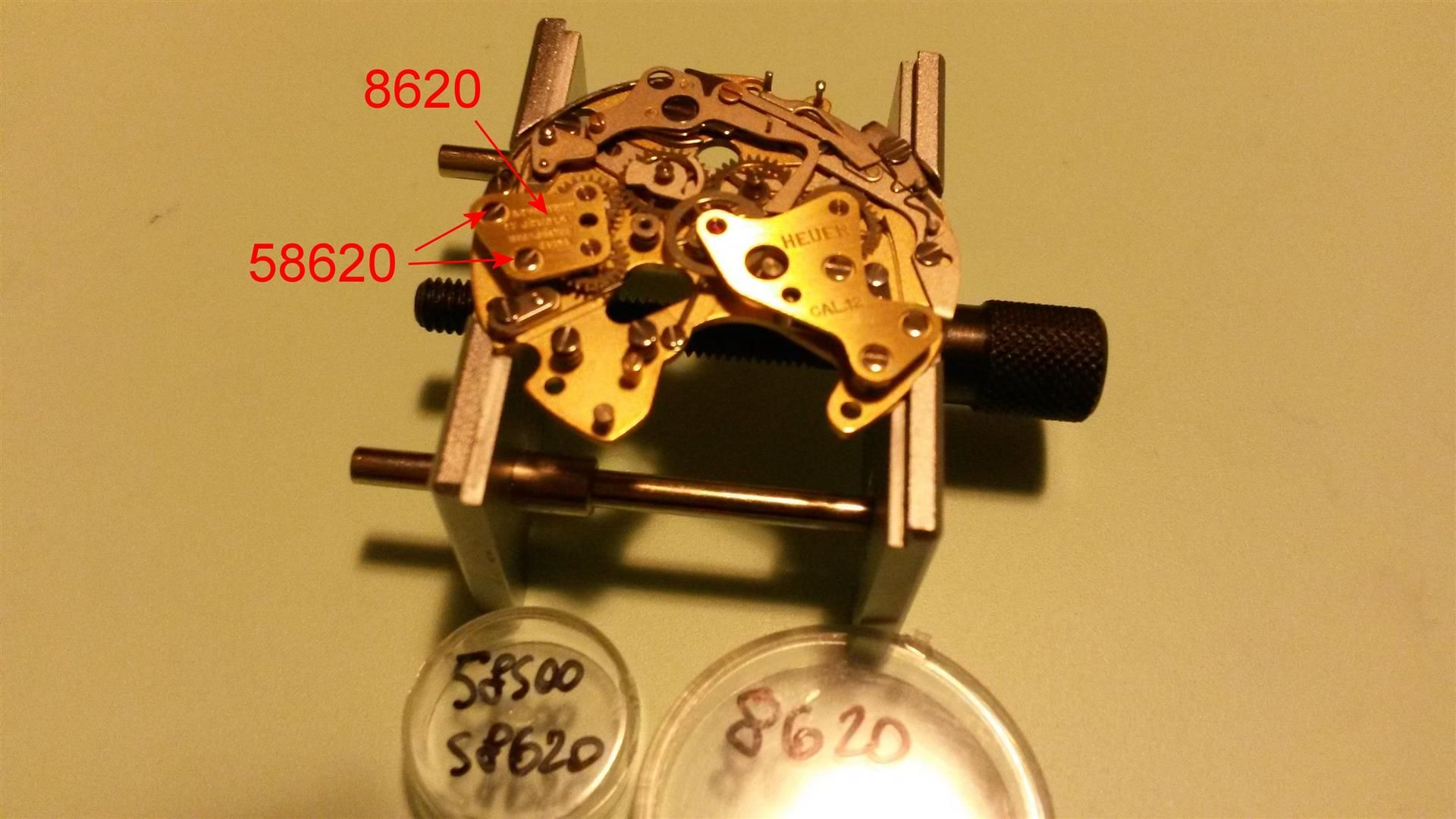

: 20) Replace the hour recorder bridge 8620 and its two screws 58620:

:

:

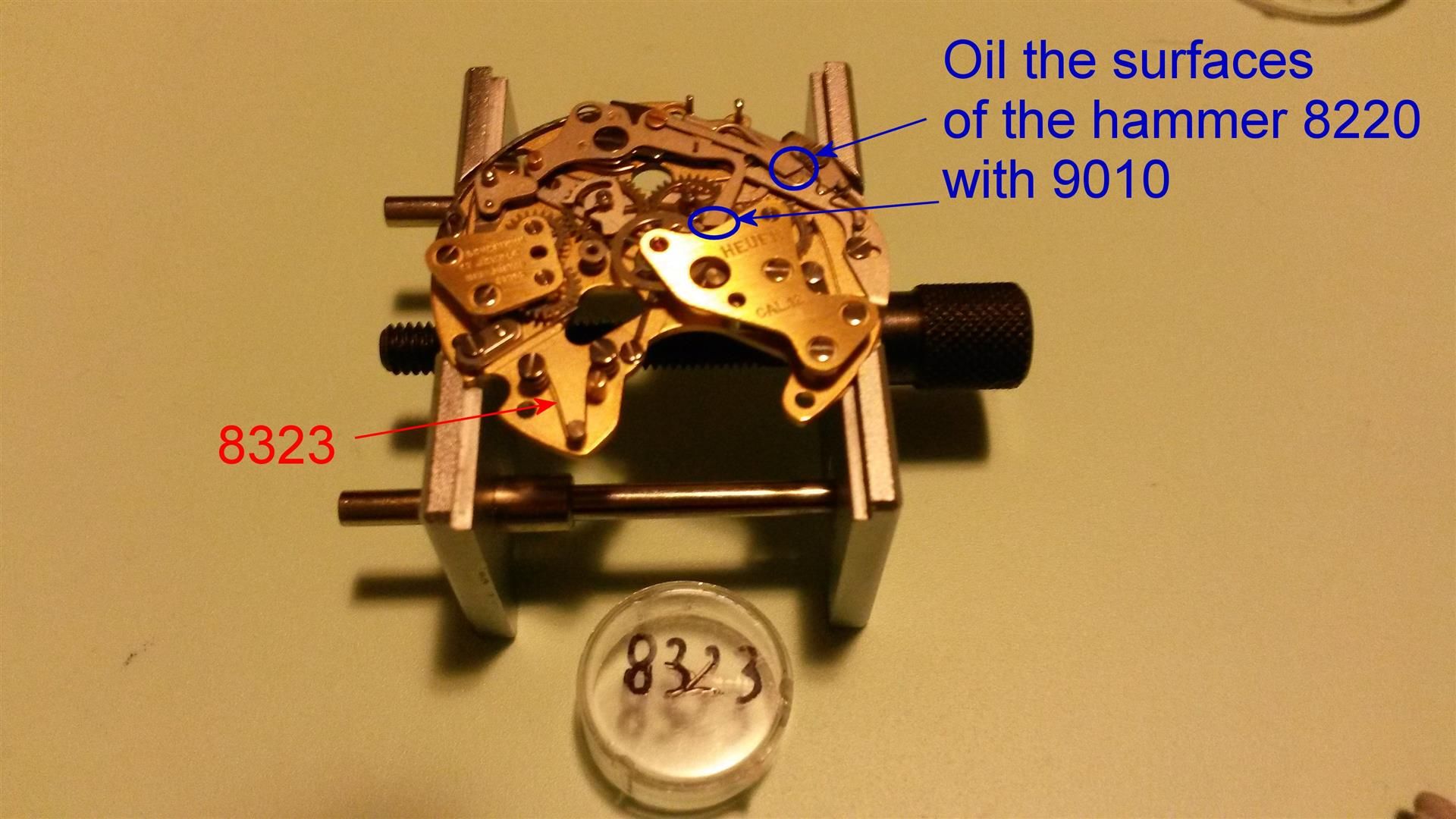

: 21) Replace the coupling clutch spring (for oscillating pinion)

: 8323, then oil both the surfaces of the hammer 8220 (essential

: to avoid rubbing when the hammer beats on the heart cams of the

: wheels 8000 and 8020):

:

:

: 22) Replace the coupling clutch unit 8079/1 with its fixing screw

: 58079/1 and check that it moves freely stopping between the two

: other screws 58079/1 (the first ones replaced at the beginning

: of the reassembling procedure):

:

:

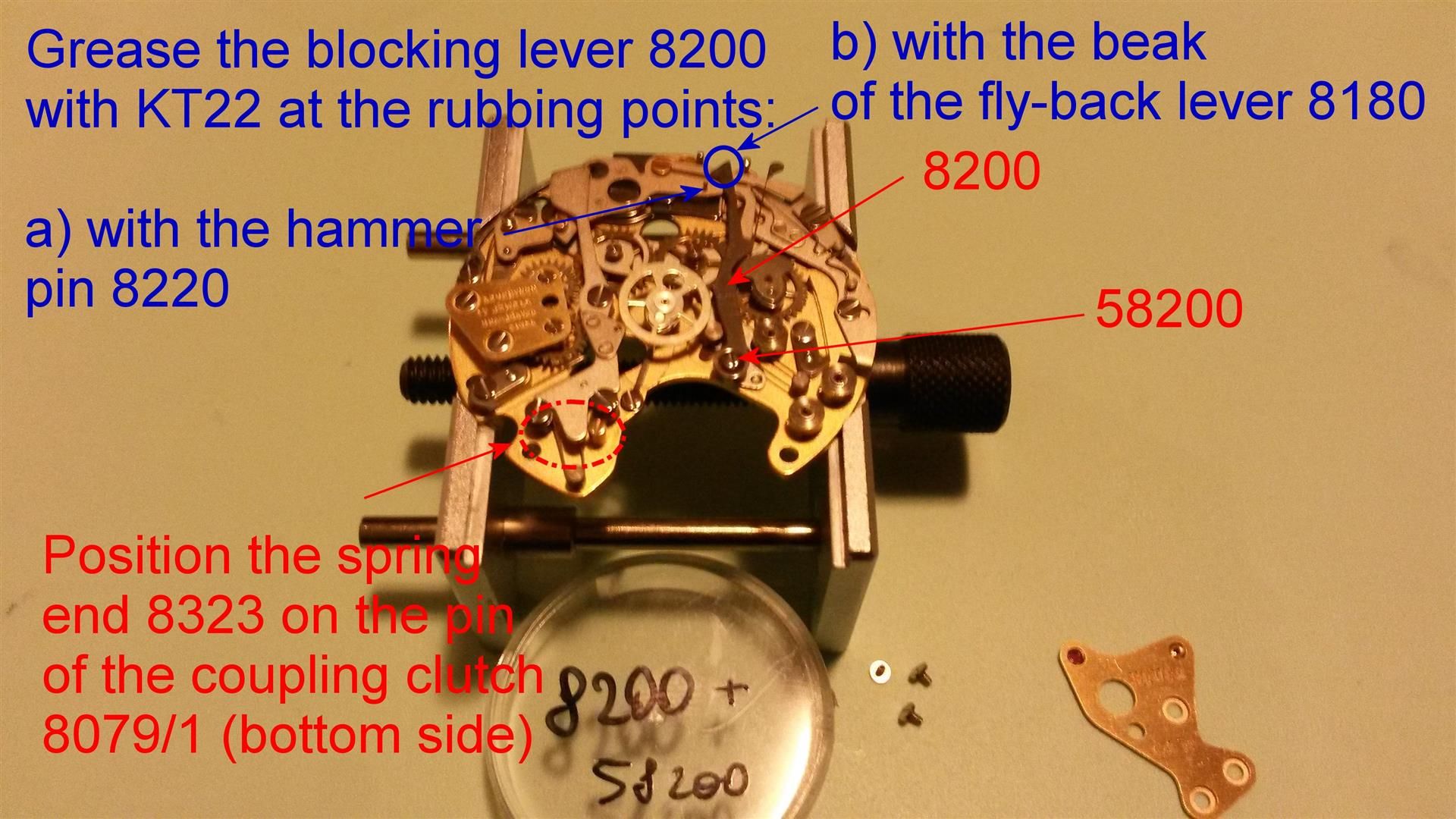

: 23) Now you can position the spring 8323 on the pin located on the

: bottom side of the coupling clutch 8079/1 in order to tension

: the coupling clutch in the rest position (when the chronograph

: is disengaged the oscillating pinion 8086 spins freely not

: engaging the chronograph central runner 8000, the travel done

: from the oscillating pinion - that is its penetration into the

: teeth of the 8000 wheel - is regulated by the golden eccentric

: located below one of the screws 58079/1).

: Then remove the chronograph bridge 8500 and position the blocking

: lever 8200 and its screw 58200, then replace the bridge 8500 and

: secure firmly its three screws.

: The blocking lever 8200 has the function to block the chronograph

: wheel 8000 (and thus the central second hand) during the stop

: phase and when the chrono is disengaged, but must free the wheel

: 8000 during the chrono running and reset phases, so verify the

: tension of the blocking lever 8200 in the stopped position of

: the chronograph passing the extremity of the blocking lever

: spring over its stop pin. Bear in mind that:

: - an excessive tension can damage the fine teeth of the chronograph

: runner 8000;

: - never turn by hand the chronograph runner 8000 while the blocking

: lever is in its stop position (that is pressed) for the reason

: above.

: Lastly grease the blocking lever 8200 at the rubbing points:

: - with the hammer pin 8220;

: - with the beak of the fly-back lever 8180.

:

:

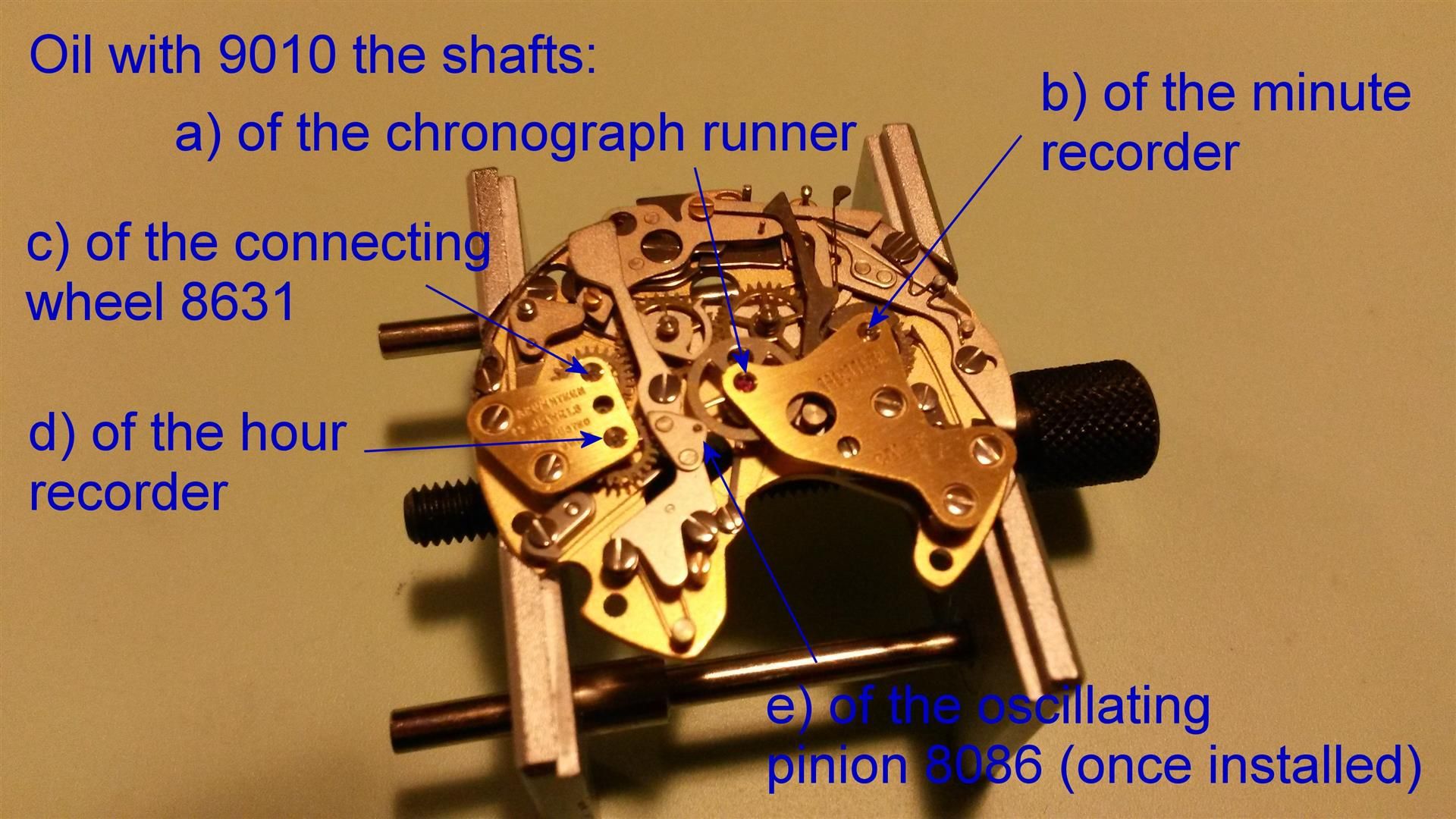

: 24) Now the chronograph module is completely assembled, so you can

: oil with 9010 the upper pivots of the wheels 8000 (chrono

: seconds), 8020 (minute recorder), 8601 (hour recorder), 8631

: (connecting wheel).

: After having replaced the chronograph module on the basic movement

: (don’t forget to oil the lower jewel of the oscillating pinion

: 8086 with oil 9010 and replace the oscillating pinion too) and

: secured it with the three blue screws 58510 don’t forget to

: oil also the upper bearing of the oscillating pinion (very

: important: the oscillating pinion always spins despite the

: chronograph is engaged or not, so if not lubricated can wear out

: prematurely and this is a really expensive and hard-to-find

: spare part nowadays):

:

:

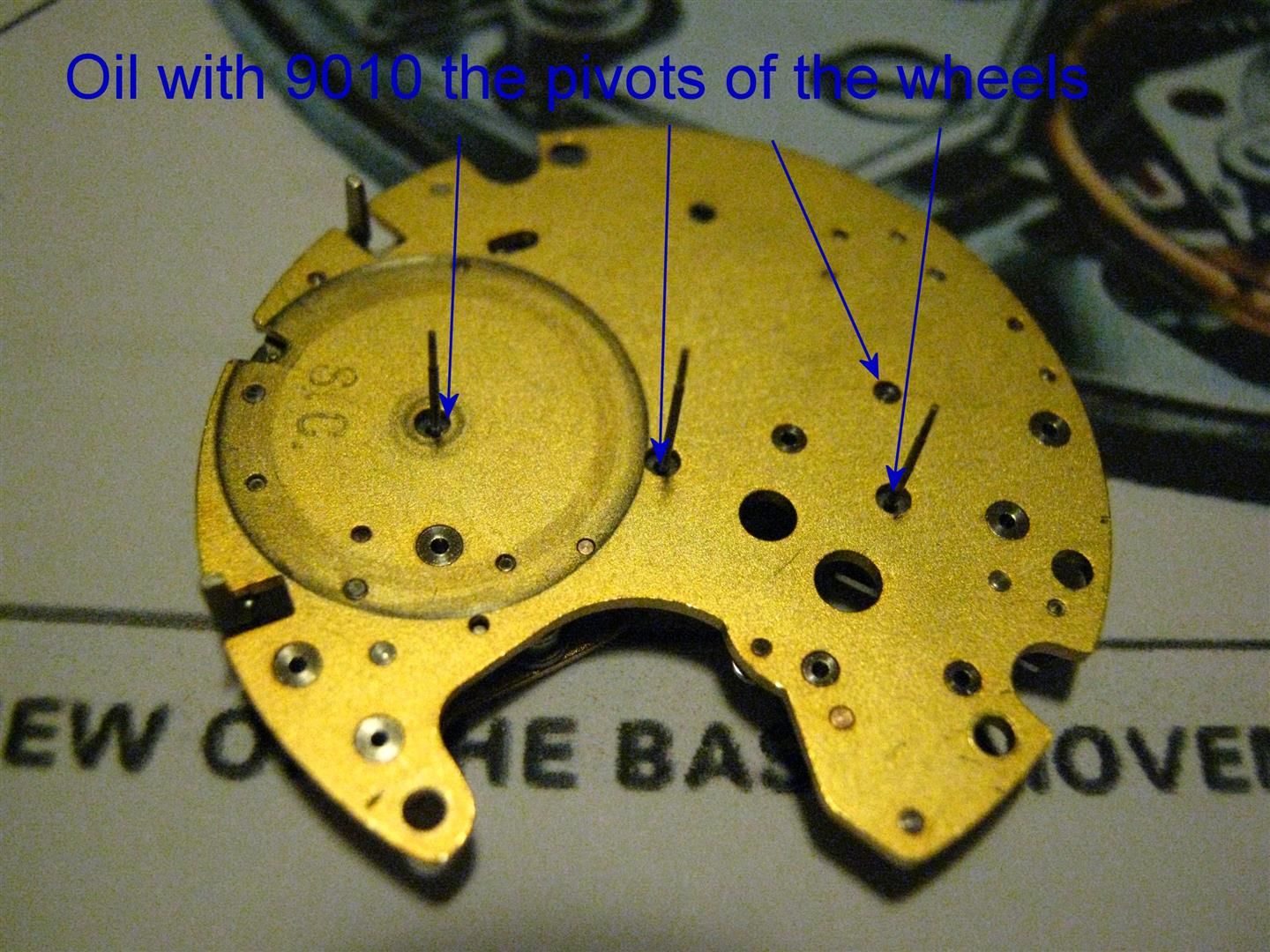

: 25) Even if the manual doesn’t suggest to oil any point on the

: lower side of the chronograph module I usually put a tiny drop

: of 9010 also on the following points, even if this is less

: important because the three shafts of the three chrono wheels

: will pass through the basic movement (the 8020 through the

: microrotor hollow arbor, the 8000 through the center pipe 163/1

: where the minute hand spins) so there will be other rubbing

: points to be lubricated on the basic movement too.

:

:

: Hope you enjoyed if you arrived until here :-)

: Gianluca

| Chronocentric and zOwie site design and contents (c) Copyright 1998-2005, Derek Ziglar; Copyright 2005-2008, Jeffrey M. Stein. All rights reserved. Use of this web site constitutes acceptance of the terms of use. | CONTACT | TERMS OF USE | TRANSLATE |