| Informational Websites | ChronoMaddox -- the legacy of Chuck Maddox | OnTheDash -- vintage Heuer website | Zowie -- Omega information |

| Discussion Forums | ChronoMaddox Forum | Heuer Forum | Omega Forum |

| Counterfeit Watchers | ChronoTools Forum | ChronoTrader Forum |

|

|

The largest independent, non-commercial, consumer-oriented resource on the Internet for owners, collectors and enthusiasts of fine wristwatches. Online since 1998. | |||||||

|

||||||||

|

||||||||

|

Vintage Heuer Discussion Forum

The place for discussing 1930-1985 Heuer wristwatches, chronographs and dash-mounted timepieces. Online since May 2003. | ||||||

| |||||||

| |||||||

Hi all,

I'm servicing my first Cal.12 and I have some doubts which would need to be solved, so I post this request hoping that someone of you could help me.

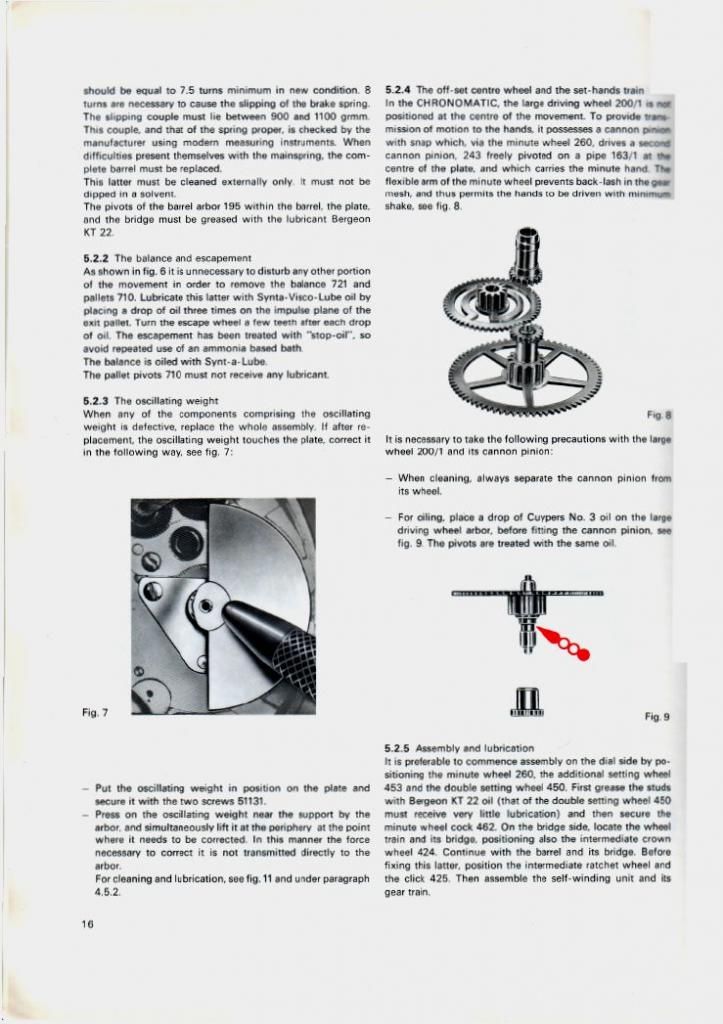

a) in the Cal.12 technical manual, among the various type of oil, there is one named "Cuypers. n.3" that is employed only in a fundamental and delicate wheel of the movement, that is the snap-in cannon pinion of the large driving wheel (part no. 200/1) and the pivots of this assembly.

This wheel, in fact, provides the transmission of the motion to the hands and possesses a cannon pinion with snap.

The assembly (driving wheel + cannon pinion) is made in such a way that, during normal use, the pinion is united with its driving wheel (I mean does not slip respect to the wheel) so motion (that is torque) can be transmitted to the hands from the pinion via the minute wheel 260, but when you set the hour (pulling the crown in the external position), the pinion must "slip" (that is it deformates) respect to its driving wheel to allow transmission of motion to the hands via the keyless work and NOT via the wheel train.

My doubt is: as this Cuypers oil does not exists anymore, which kind of oil should I use inside the arbor of the cannon pinion before re-snapping it on the driving wheel's arbor?

Should I use a liquid one (such Moebius 9020) to facilitate the slipping during the hour setting OR a more viscous one (like Microgliss D5, for example) to allow transmission of the torque to the hands (i.e. pinion must be united to the wheels to avoid that hands could not rotate as the pinion slips in normal use)?

b) Second doubt: inside the mainspring barrell is preferable to use a grease with graphite (to facilitate the slipping of the spring when the mainspring is overwinded) or the normal Bergeon KT22 (quoted into the manual as the unique grease to be used) is also OK?

I ask this because an expert watchmaker told me that, in an automatic watch you must always use grease with graphite inside the barrell and a grease without graphite does not allow the mainspring to slip when overwouned so the risk is that the barrel transmits more torque and the watch does not keep accurate time when overwinded.

Hoping in your precious help.

All my best.

Gianluca

| Chronocentric and zOwie site design and contents (c) Copyright 1998-2005, Derek Ziglar; Copyright 2005-2008, Jeffrey M. Stein. All rights reserved. Use of this web site constitutes acceptance of the terms of use. | CONTACT | TERMS OF USE | TRANSLATE |